Self-adaptive flow control system and application thereof to high-temperature and high-salinity oil reservoir

A high-temperature, high-salt, self-adaptive technology, applied in the fields of production fluids, drilling compositions, wellbore/well components, etc., can solve the problems of low emulsion sweep efficiency, achieve outstanding economic benefits, improve oil recovery, Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

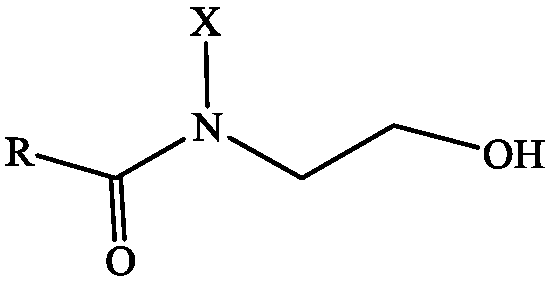

[0030] The oil-water interfacial tension of embodiment 1 adaptive fluidity control system

[0031] The mineralization degree of preparation is 30000mg / L (Ca 2+ , Mg 2+ The concentration is 500mg / L) and 210236mg / L (Ca 2+ , Mg 2+ Mineralized water with a concentration of 11324 mg / L), add 0.2% N, N-bishydroxyethyl alkylamide, 0.15% C12 / C14 glycoside surfactant, 0.05% glycerin, and stir for 1 to 3 hours. Obtain an adaptive fluidity control system; use a TX500C rotating interfacial tensiometer to measure the relationship between the adaptive fluidity control system and two degassed crude oils (viscosities at 80°C are 25.1mPa·s and 8.3mPa·s respectively) at 80°C. Interfacial tension, measuring time 2h, to obtain a stable interfacial tension value. The self-adaptive fluidity control system is 3.0~22×10 4 The high salinity condition of mg / L can keep the interfacial tension of oil and water at 10 -2 ~10 -3 mN / m order of magnitude, showing excellent oil washing performance, the r...

Embodiment 2

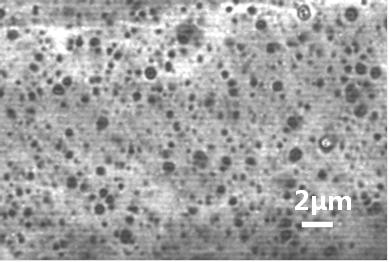

[0034] Embodiment 2 Self-adaptive fluidity control system forms the viscosity of emulsion with crude oil

[0035] The mineralization degree of preparation is 30000mg / L (Ca 2+ , Mg 2+ The concentration is 500mg / L) and 210236mg / L (Ca 2+ , Mg 2+ Mineralized water with a concentration of 11324mg / L), sequentially add 0.2% N-hydroxyethyl alkylamide, 0.15% C12 / C14 glycoside surfactant, 0.05% glycerin, and stir for 1 to 3 hours to obtain self-adaptive Mobility control system; configure and seal the adaptive fluidity control system and crude oil according to the oil-water ratio of 5:5, 4:6, 3:7, 2:8, 1:9, and place them in an oil tank with a magnetic stirring device. in a bath; then in an oil bath at 95°C, stir magnetically for 1 hour, and observe the emulsification. After stirring, use a high-temperature and high-pressure Haake rheometer to measure the viscosity of the emulsion, crude oil, and salinity water at 140°C. See the table 2. Table 3. At high temperature and high salinity,...

Embodiment 3

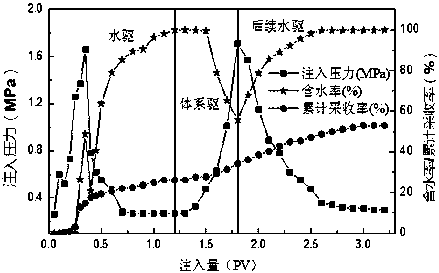

[0042] Example 3 Enhanced Oil Recovery Performance of Adaptive Mobility Control System

[0043] The mineralization degree of preparation is 30000mg / L (Ca 2+ , Mg 2+ The concentration is 500mg / L) and 210236mg / L (Ca 2+ , Mg 2+ Mineralized water with a concentration of 11324 mg / L), add 0.2% N, N-bishydroxyethyl alkylamide, 0.15% C12 / C14 glycoside surfactant, 0.05% glycerin, and stir for 1 to 3 hours. Obtain an adaptive fluidity control system; in the displacement experiment of artificial simulated core (45×45×300mm, three-layer heterogeneity, average porosity 19.4%, gas permeability 100 / 200 / 500mD), temperature 104°C , the viscosity of crude oil is 18.1mPa s (104°C), and the original oil-bearing water saturation is 70.3%. In the water flooding stage, it is affected by heterogeneity and unfavorable water-oil mobility ratio. The oil recovery degree of water flooding is low, and the water cut The 98% oil recovery rate is 31.2%, and the remaining (residual) oil saturation is 48.4%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com