Method for regulating and controlling photoelectric haze and ultraviolet filtration effect of modified nano-cellulose film

A nanocellulose and filtration technology, which is applied in the field of biomass optoelectronic nanomaterials, can solve the problem that the haze value of nanocellulose films cannot be regulated, and achieves enhanced ultraviolet filtration performance, increased use range, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (3) Preparation of modified nanocellulose film

[0034] Take 12-36 mg of TEMPO-oxidized cellulose nanofibers dry, ultrasonically disperse them in 10-30 mL of deionized water, then weigh 3-9 mg of modifier Zn(II) terpyridine complex and dissolve them in 2-6 ml of dimethyl sulfoxide solution, then mixed and stirred for 12 to 24 hours. Vacuum filtration is carried out to obtain a modified nanocellulose film, that is, a modified nanopaper.

[0035] The reaction formula is shown below.

[0036]

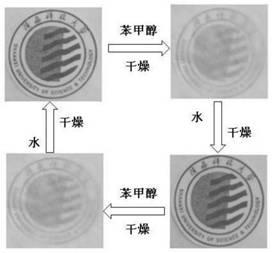

[0037](4) Treatment of nanocellulose films with different solvents

[0038] (401) Treating Unmodified Nanocellulose Films with Different Solvents

[0039] Put the unmodified nanocellulose film in a weighing bottle, add 10-50ml of solvent, take it out after soaking for 10-60min, remove excess solvent, and obtain the unmodified nanocellulose film after solvent treatment.

[0040] (402) Treatment of modified nanocellulose films with different solvents

[0041] Put the modified ...

Embodiment 1

[0048] Weigh 3g of dry bleached coniferous wood fibers in deionized water, and shear at high speed for 5min, so that the fibers are evenly dispersed in the water. Add TEMPO (0.01mmol / g) and NaBr (6.0mmol / g) aqueous solutions in turn, add NaOH aqueous solution to adjust the pH value to 10, then add NaClO (6.0mmol / g) solution to the system, and stir for 3h. After the reaction is completed, the pH of the reaction solution is adjusted to neutral by dilute hydrochloric acid to obtain a TEMPO-oxidized cellulose suspension. Wash with deionized water until neutral, adjust to a concentration of 0.03 wt% cellulose suspension, perform high-pressure homogenization treatment, and homogenize 40 times under a pressure of 60 MPa to obtain TEMPO-oxidized cellulose nanofibers.

[0049] 5mmol (0.98g) of 3,4,5-trimethoxybenzaldehyde and 10mmol (7.7g) of KOH particles were dissolved in 50ml of ethanol solution, and then 10mmol (1.2g) of 2-acetylpyridine was added dropwise. The solution was stirre...

Embodiment 2

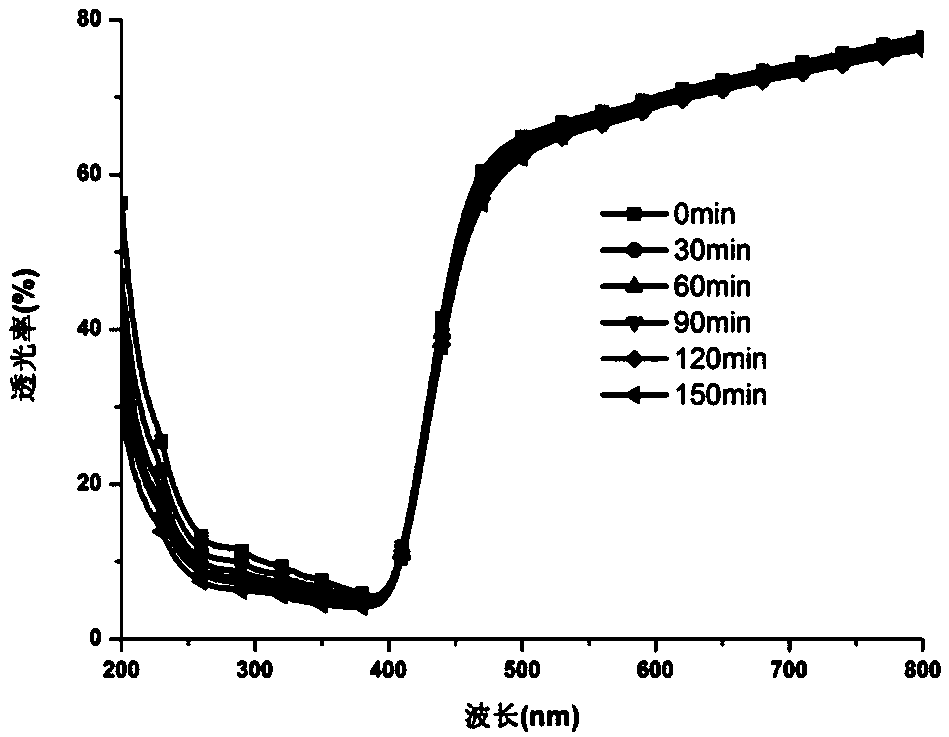

[0062] Put 5 pieces of modified nanocellulose films in benzyl alcohol treatment respectively, but the soaking time is 0, 30min, 90min, 120min and 150min respectively, remove excess benzyl alcohol solvent, and obtain modified nanocellulose after benzyl alcohol solvent treatment. Thin film, carry out light transmittance test, obtain ultraviolet-visible light transmittance spectrum, the result is as follows image 3 shown. From image 3 It can be seen that compared with the modified nanocellulose film without benzyl alcohol treatment, the absorption of the modified nanocellulose film treated with benzyl alcohol in the ultraviolet region is significantly reduced, indicating that after solvent treatment, it has high efficiency. Ultraviolet filtration performance, and with the prolongation of treatment time, the ultraviolet filtration performance is also continuously enhanced, which is due to the increase of haze with the prolongation of treatment time, that is to say, the increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com