Preparation method and application of super-crosslinked porous polyion liquid material

A technology of polyionic liquid and ionic liquid, which is applied in the field of preparation of hypercrosslinked porous polyionic liquid materials, can solve problems such as reducing surface energy, and achieve the effects of simple reuse, high content and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation method of hypercrosslinked porous polyionic liquid material, it comprises following specific steps:

[0020] Step 1, the preparation of rigid diene ionic liquid monomer;

[0021] Weigh 2-vinylimidazole and 4-chloromethylstyrene, mix them according to the ratio of the amount of substances as 1:1, add a polymerization inhibitor, the amount of polymerization inhibitor is 1% of the total mass, add tetrahydrofuran, and make 40% After solution, stir at 60°C for 48 hours to obtain the corresponding ionic liquid, wash with ethyl acetate, diethyl ether, and petroleum ether three times in sequence, and then vacuum-dry at 60°C to obtain the rigid diene ionic liquid monomer;

[0022] After dissolving the rigid diene ionic liquid monomer in acetone, add it to potassium hexafluorophosphate for exchange, the molar amount of salt is 1.5 times that of the monomer, heat and stir at 60°C, and add 1% polymerization inhibitor, exchange After filtering to remove the co...

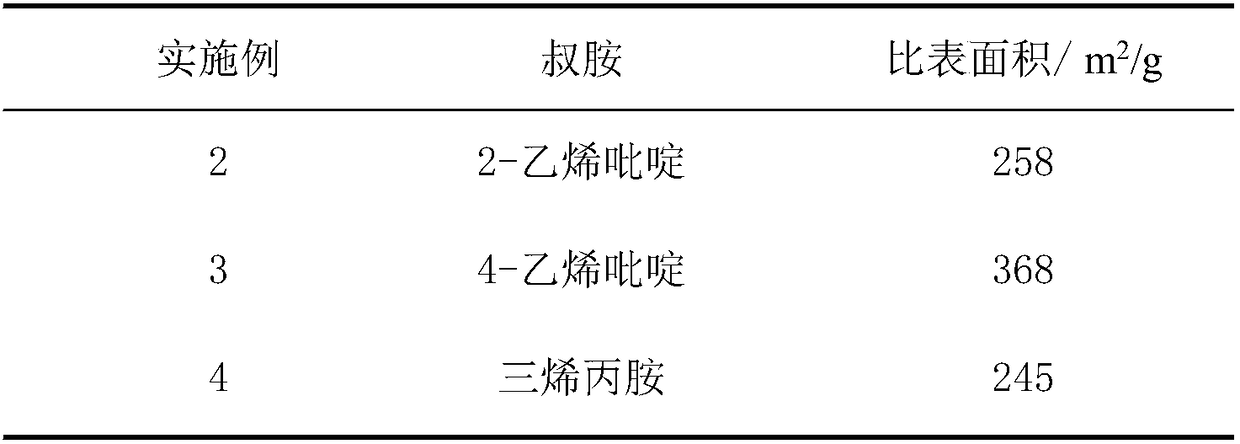

Embodiment 2-4

[0026] Except for the following differences, all the other are the same as in Example 1, using the tertiary amine compounds shown in Table 1 respectively.

[0027] Table 1

[0028]

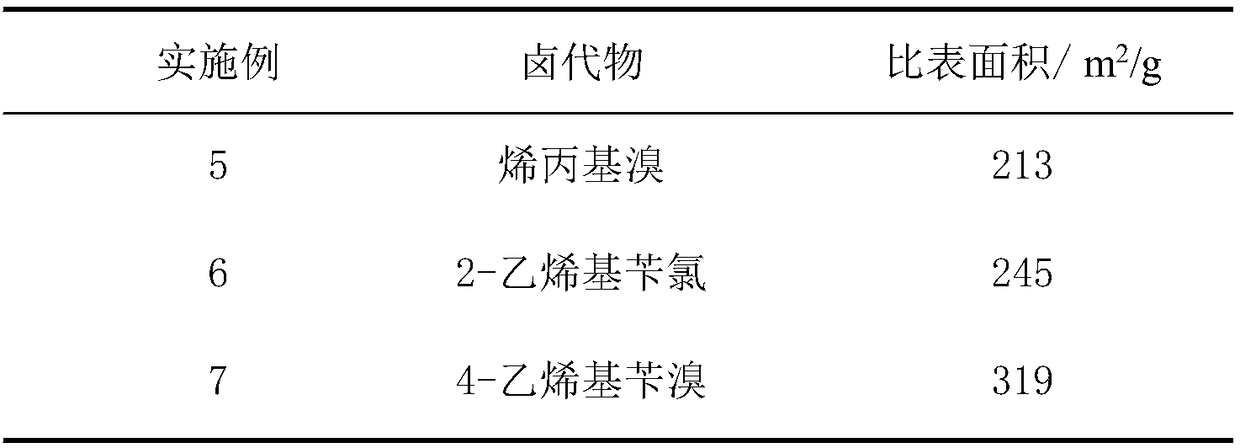

Embodiment 5-7

[0030] Except for the following differences, the rest are the same as in Example 1, using allyl halides or styrene benzyl halides shown in Table 2, respectively.

[0031] Table 2

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com