Method for preparing nitrogen-doped porous carbon for supercapacitor by utilizing metal organic framework compound

A metal-organic framework and supercapacitor technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, carbon preparation/purification, etc., can solve problems such as inability to uniformly recombine, affect nano-CaCO3 pore-forming effect, etc., and achieve good results Electrochemical performance, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

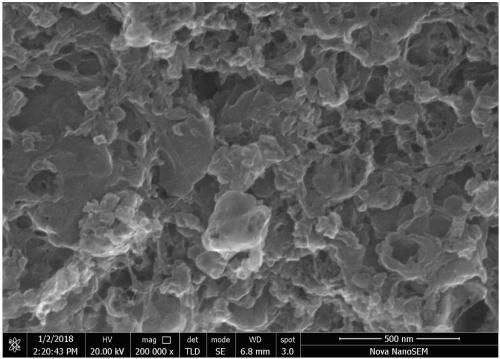

Image

Examples

Embodiment 1

[0026] Weigh 200mg of nano-CaCO with a size of 150nm 3 Put it into a beaker filled with 100mL of absolute ethanol and deionized aqueous solution with a volume ratio of 1:1, then add 100mg of tris(hydroxymethyl)aminomethane and 100mg of dopamine hydrochloride, stir at room temperature for 12h, take it out and use deionized Rinse with water until neutral, and freeze-dry to obtain nano-CaCO 3 @PDA particles.

[0027] Take 200mg CaCO 3 Disperse @PDA into 50ml of methanol, add 600mg of PVP and 300mg of zinc nitrate, stir to dissolve, and make solution A. Weigh 900 mg of 2-methylimidazole and disperse it in 50 ml of methanol as solution B. During the stirring process, quickly pour the B solution into the A solution, and let it stand for 2 hours to obtain CaCO 3 @PDA @ZIF-8.

[0028] CaCO 3 @PDA@ZIF-8 was heated to 700 °C for 1 h at a heating rate of 5 °C / min in an argon atmosphere. After cooling to room temperature, the template agent was removed by acid washing with 1 mol / L H...

Embodiment 2

[0030] Weigh 200 mg of nano-CaCO with a size of 50 nm 3 , put into a beaker containing 100mL absolute ethanol and deionized aqueous solution with a volume ratio of 1:1, then add 100mg tris(hydroxymethyl)aminomethane and 100mg dopamine hydrochloride, stir at room temperature for 24h, take it out and use it Rinse with ionized water to neutrality, and freeze-dry to obtain nano-CaCO 3 @PDA particles.

[0031] Take 200mg CaCO 3 Disperse @PDA into 50ml of methanol, add 1g of PVP and 900mg of zinc nitrate, stir to dissolve, and make solution A. Weigh 3.3g of 2-methylimidazole and disperse it in 50ml of methanol as solution B. During the stirring process, quickly pour B solution into A solution and let it stand for 4h to obtain CaCO 3 @PDA @ZIF-8.

[0032] CaCO 3 @PDA@ZIF-8 was heated to 800 °C for 3 h at a heating rate of 5 °C / min in an argon atmosphere. After cooling to room temperature, the template agent was removed by acid washing with 1 mol / L HCl solution to obtain nitrogen...

Embodiment 3

[0034] Weigh 400mg of nano-CaCO with a size of 80nm 3 , put into a beaker containing 100mL absolute ethanol and deionized aqueous solution with a volume ratio of 1:1, then add 100mg tris(hydroxymethyl)aminomethane and 100mg dopamine hydrochloride, stir at room temperature for 18h, take it out and use it Rinse with ionized water to neutrality, and freeze-dry to obtain nano-CaCO 3 @PDA particles.

[0035] Take 200mg CaCO 3Disperse @PDA in 50ml of methanol, add 2g of PVP, 1.2g of zinc nitrate, stir to dissolve, and make solution A. Weigh 4g of 2-methylimidazole and disperse it in 50ml of methanol as solution B. During the stirring process, quickly pour B solution into A solution and let it stand for 12h to obtain CaCO 3 @PDA @ZIF-8.

[0036] CaCO 3 @PDA@ZIF-8 was heated to 900 °C for 1 h at a heating rate of 5 °C / min in an argon atmosphere. After cooling to room temperature, the templating agent was removed by acid washing with 1 mol / L HCl solution to obtain nitrogen-doped p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com