Finishing hopper, packaging assembly, packaging system and packaging method

A technology of packaging components and hoppers, which is applied in the direction of special packaging objects, packaging, transportation packaging, etc., can solve the problems of increasing the difficulty of storage and transportation, difficulty in forming a packaging state, and excessive volume, so as to achieve the goal of not being easy to interfere, convenient for storage and transportation, and saving procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

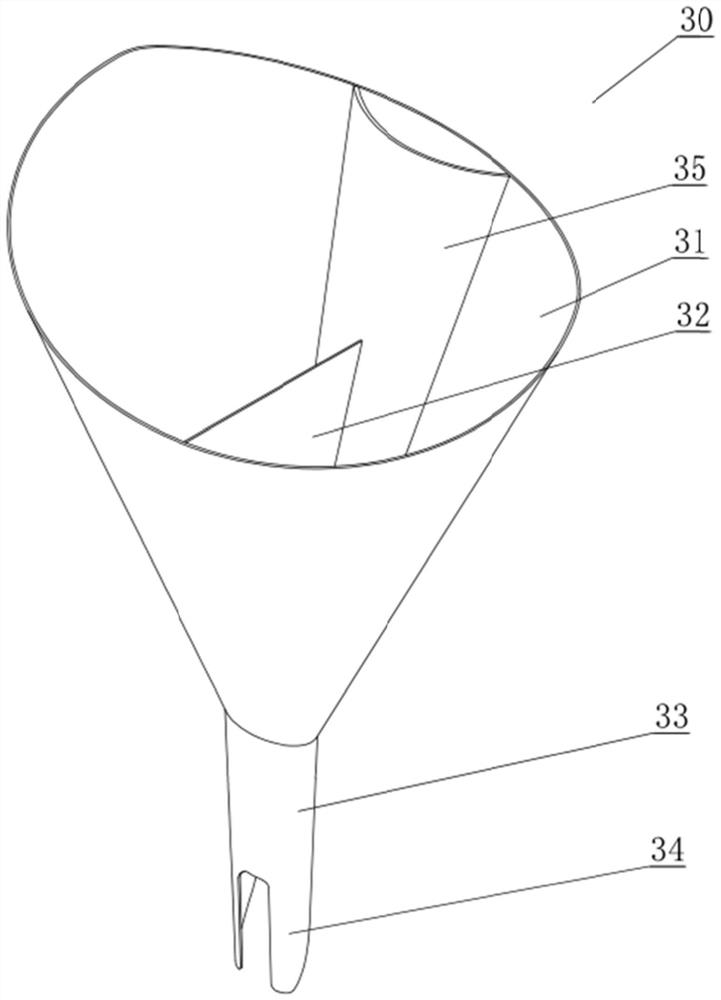

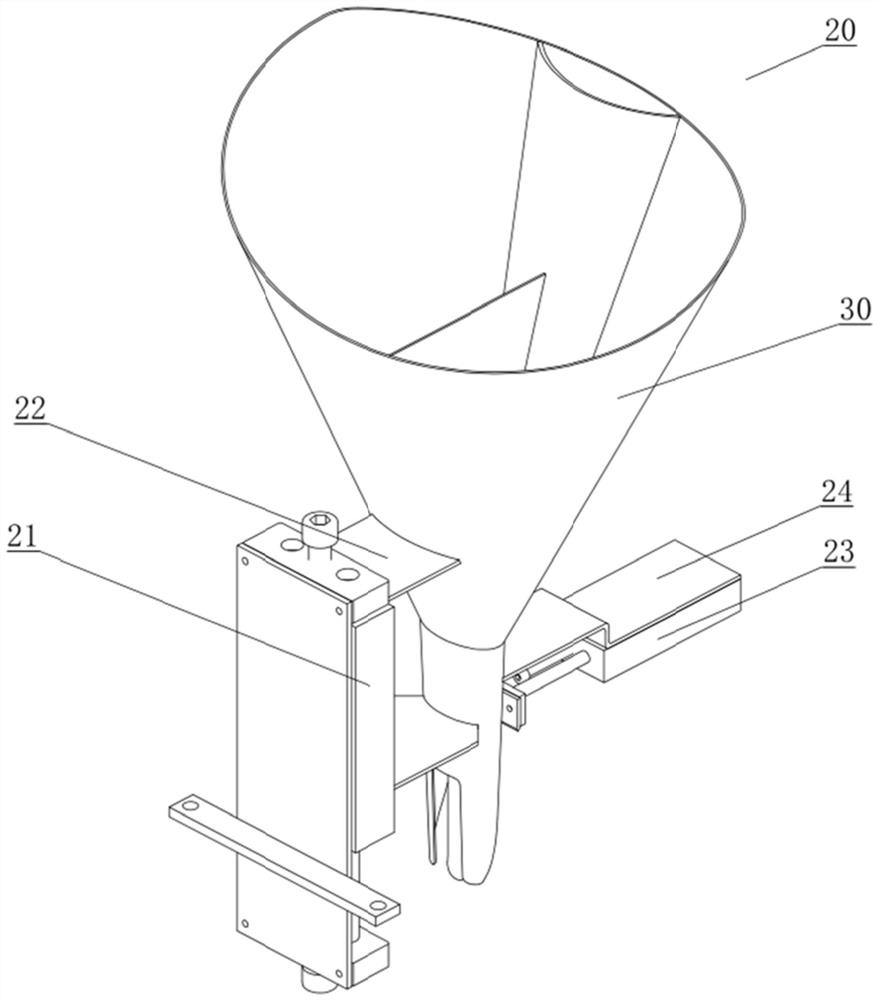

[0061] Such as figure 1 and figure 2 As shown, a sorting hopper 30 through which the packaged object enters the packaging bag, the hopper includes:

[0062] The funnel-shaped feeding arrangement area 31, the upper end of the caliber is larger than the lower end;

[0063] At least one partition 32 is arranged in the middle of the feeding arrangement area 31, and the partition 32 divides at least a part of the feeding arrangement area 31 in the height direction into at least two areas whose diameter is smaller than the length of the packaged object;

[0064] And the buffer area 33 communicated with the lower end of the feeding finishing area 31, the lower end of the buffer area 33 leads to the packaging bag direction.

[0065] Since the partition 32 separates at least a part of the feeding arrangement area 31 in the height direction into at least two regions whose diameter is smaller than the length of the packaged object, after causing the rod-shaped packaged object to fall ...

Embodiment 2

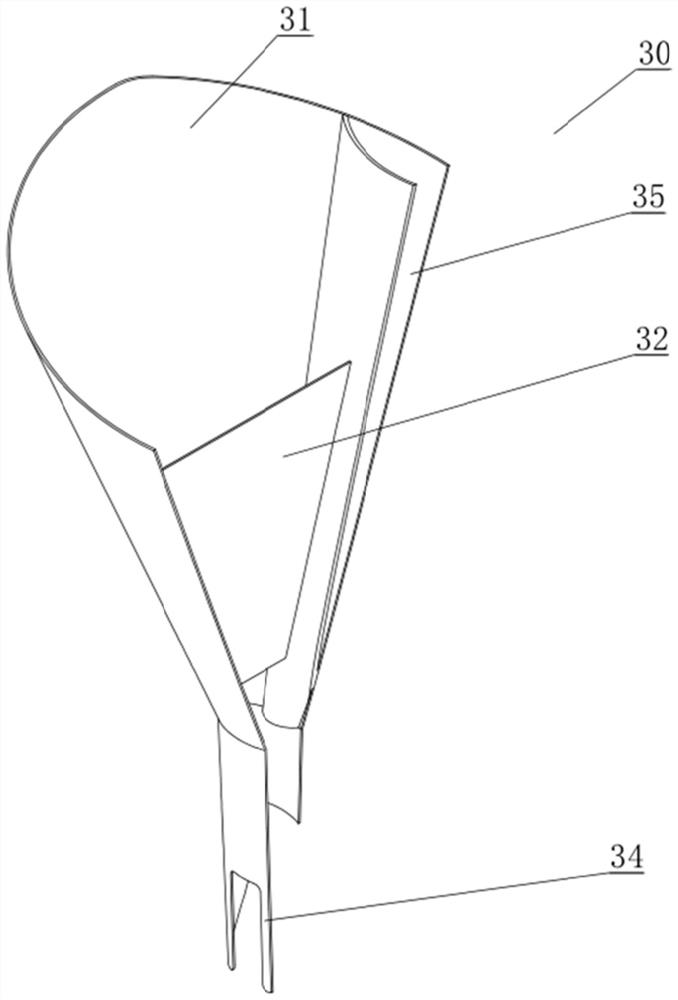

[0069] Such as figure 1 and figure 2 As shown, a sorting hopper 30 through which the packaged object enters the packaging bag, the hopper includes:

[0070] The funnel-shaped feeding arrangement area 31, the upper end of the caliber is larger than the lower end;

[0071] At least one partition 32 is arranged in the middle of the feeding arrangement area 31, and the partition 32 divides at least a part of the feeding arrangement area 31 in the height direction into at least two areas whose diameter is smaller than the length of the packaged object;

[0072] And the buffer area 33 communicated with the lower end of the feeding finishing area 31, the lower end of the buffer area 33 leads to the packaging bag direction.

[0073] An independent label channel 35 is separated inside the hopper, and the label channel 35 extends from the upper part of the hopper to the buffer zone 33 and leads to the direction of the packaging bag.

[0074] In this example, if figure 1 and figur...

Embodiment 3

[0077] Such as figure 1 and figure 2 As shown, a sorting hopper 30 through which the packaged object enters the packaging bag, the hopper includes:

[0078] The funnel-shaped feeding arrangement area 31, the upper end of the caliber is larger than the lower end;

[0079] At least one partition 32 is arranged in the middle of the feeding arrangement area 31, and the partition 32 divides at least a part of the feeding arrangement area 31 in the height direction into at least two areas whose diameter is smaller than the length of the packaged object;

[0080] And the buffer area 33 communicated with the lower end of the feeding finishing area 31, the lower end of the buffer area 33 leads to the packaging bag direction.

[0081] The lower end of the hopper buffer area 33 communicates with the opening area 34, and the opening area 34 has at least one opening along the circumferential direction, and when the packaged object falls into the packaging bag, the opening area 34 is at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com