High-strength planting slope protection geotextile with sandwich structure and preparation method of high-strength planting slope protection geotextile with sandwich structure

A high-strength, sandwich technology, applied in infrastructure engineering, excavation, non-woven fabrics, etc., can solve the problems of limited application of slope protection materials, etc., achieve convenient and fast paving construction, high fertility and water retention capacity, and realize mechanized production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

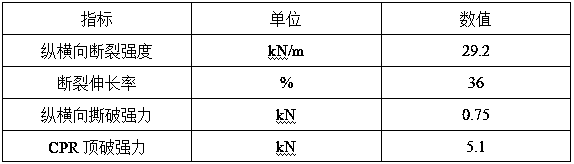

Embodiment 1

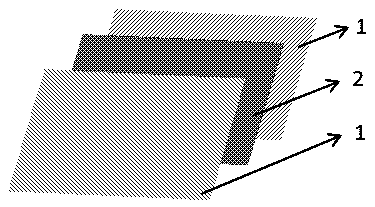

[0028] Such as figure 1 As shown, a high-strength vegetation slope protection geotextile with a sandwich structure, the geotextile includes two layers of short-fiber geotextiles 1, and a vegetation layer 2 sandwiched between two layers of short-fiber geotextiles, the short-fiber geotextile The layer and the vegetation layer are fixedly connected by acupuncture technology and form a whole, forming a sandwich structure.

[0029] The short fiber geotextile layer is made of viscose fiber through needle punching and prepunching. The cut length of viscose fiber is 35-75mm, and the fineness is 1.1-6.6dtex.

[0030] The viscose fiber is viscose cotton staple fiber. The cut length of viscose cotton staple fiber is 35-40mm, and the fineness is 1.1-2.8dtex.

[0031] The vegetation layer is natural plant fiber. The amount of natural plant fiber added is 300-1200g / m 2 . On the one hand, the vegetation layer can provide the necessary nutrients for plant growth, and on the other hand, ...

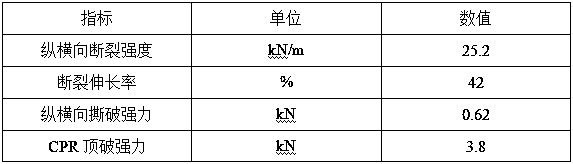

Embodiment 2

[0049] A high-strength vegetation slope protection geotextile with a sandwich structure, the geotextile includes two layers of short-fiber geotextiles, and a vegetation layer sandwiched between the two layers of short-fiber geotextiles, the short-fiber geotextile layer and the vegetation layer are made of The needling process securely connects and forms a whole, forming a sandwich structure.

[0050] The short fiber geotextile layer is made of viscose fiber through needle punching and prepunching. The cut length of viscose fiber is 35-75mm, and the fineness is 1.1-6.6dtex.

[0051] The viscose fiber is viscose cotton staple fiber. The cut length of viscose cotton staple fiber is 35-40mm, and the fineness is 1.1-2.8dtex.

[0052] The vegetation layer is natural plant fiber. The amount of natural plant fiber added is 300-1200g / m 2 . On the one hand, the vegetation layer can provide the necessary nutrients for plant growth, and on the other hand, it has a superior water rete...

Embodiment 3

[0070] A high-strength vegetation slope protection geotextile with a sandwich structure, the geotextile includes two layers of short-fiber geotextiles, and a vegetation layer sandwiched between the two layers of short-fiber geotextiles, the short-fiber geotextile layer and the vegetation layer are made of The needling process securely connects and forms a whole, forming a sandwich structure.

[0071] The short fiber geotextile layer is made of viscose fiber through needle punching and prepunching. The cut length of viscose fiber is 35-75mm, and the fineness is 1.1-6.6dtex.

[0072] The viscose fiber is viscose cotton staple fiber. The cut length of viscose cotton staple fiber is 35-40mm, and the fineness is 1.1-2.8dtex.

[0073] The vegetation layer is natural plant fiber. The amount of natural plant fiber added is 300-1200g / m 2 . On the one hand, the vegetation layer can provide the necessary nutrients for plant growth, and on the other hand, it has a superior water rete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com