Underwater drilling fast blockage air bag and blockage method thereof

An airbag and fast technology, applied in sealing/isolation, earthmoving, wellbore/well components, etc., can solve the problems of limited operation time, long operation time, high cost, etc., and achieve good adhesion, bonding Firm, not falling off, high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

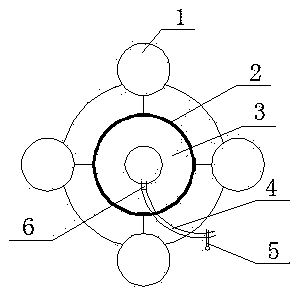

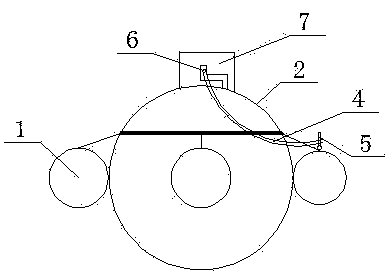

[0031] Such as figure 1 , 2 As shown in , 3, the underwater drilling fast plugging airbag of the present invention comprises a spherical airbag body 3 of rubber material, the top of the airbag body has a cylindrical protrusion 7, and the outer wall of the cylindrical protrusion is provided with an air inlet and outlet 6, The air inlet and outlet communicate with the inner cavity of the airbag body through the passage provided inside the cylindrical protrusion. An air guide tube 4 is installed at the air inlet and outlet, and a control valve 5 is arranged at the other end of the air guide tube; a connecting ring 2 is set on the air bag body, and the connecting ring Located on the upper part of the airbag body, several connecting ropes are evenly distributed along the circumferential direction on the connecting ring, and the end of the connecting ropes is provided with a drop body 1 .

[0032] When in use, first consult the relevant geological data or use geophysical prospectin...

Embodiment 2

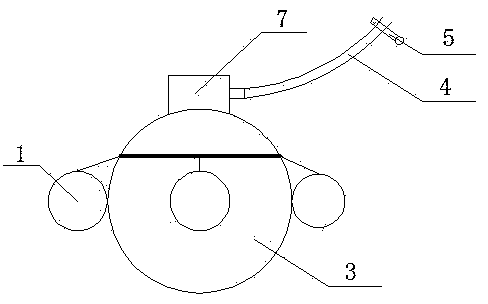

[0034] Such as Figure 4 , 5 As shown, the underwater drilling fast plugging airbag of the present invention comprises an ellipsoidal airbag body 3 of rubber material, the top of the airbag body has a cylindrical protrusion 7, and the outer wall of the cylindrical protrusion is provided with an air inlet and outlet 6, and the air inlet and outlet The channel provided inside the cylindrical protrusion communicates with the inner cavity of the airbag body. An air guide tube 4 is installed at the air inlet and outlet, and a control valve 5 is provided at the other end of the air guide tube; a connecting ring 2 is set on the air bag body, and the connecting ring is located On the upper part of the body, several connecting ropes are evenly distributed along the circumferential direction on the connecting ring, and the end of the connecting ropes is provided with a drop body 1 .

[0035] The above-mentioned ellipsoidal airbag body 3 is injected with a high-performance inorganic pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com