High-strength impact-resistant corrugated cardboard

A corrugated cardboard and corrugated paper technology, applied in the field of corrugated cardboard, can solve the problems of limited strength and impact resistance of corrugated cardboard, reduce packaging space, waste resources and other problems, and achieve the effects of not easy to puncture, save space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

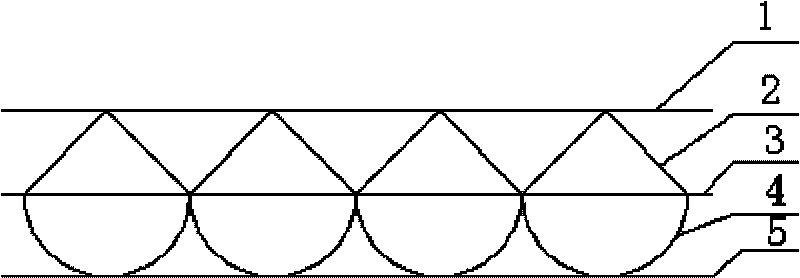

[0018] refer to figure 1 , the present embodiment includes an outer layer paper 1, a V-shaped corrugated paper core 2, an intermediate layer 3, a semicircular corrugated paper core 4 and a bottom layer of paper 5, forming a five-layer corrugated cardboard structure; the outer layer paper 1 and the intermediate layer 3 is a V-shaped corrugated paper core 2, and between the intermediate layer 3 and the bottom surface paper 5 is a semicircular corrugated paper core 4.

[0019] The outer surface paper 1 and the bottom surface paper 5 are 200g kraft paper; the intermediate layer adopts 200g corrugated medium paper; the V-shaped corrugated paper core 2 and the semicircular corrugated paper core 4 have the same height; the V-shaped corrugated paper core 2 and the semicircular corrugated paper core 4, the spans between the troughs are equal, and the spans between the peaks are equal; the direction of the grooves of the V-shaped corrugated paper core 2 and the direction of the grooves ...

Embodiment 2

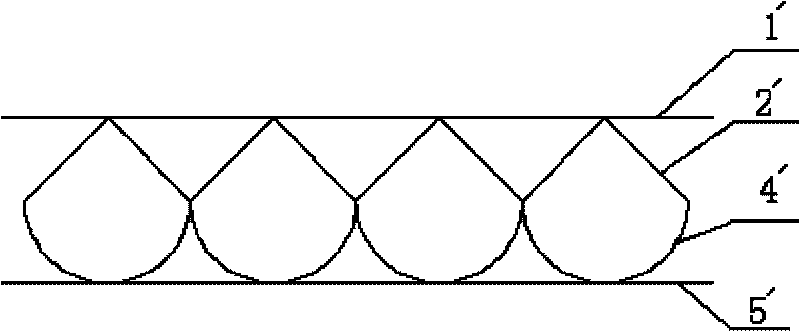

[0022] refer to figure 2 , this embodiment includes outer layer paper 1', V-shaped corrugated paper core 2', semi-circular corrugated paper core 4' and bottom surface paper 5', forming a 4-layer corrugated board structure; V-shaped corrugated paper core 2' and semi-circular corrugated paper The crests and wave bottoms formed between the cores 5' are bonded to each other on the same vertical plane; the outer surface paper 1' and the bottom surface paper 5' are 200g kraft paper.

[0023] In this embodiment, there is no intermediate layer between the V-shaped corrugated paper core 2' and the semicircular corrugated paper core 5', so that the formed wave crests and wave bottoms are bonded to each other on the same vertical plane. Because the two sides of the semicircular corrugated paper core 4' give an axial force to the two sides of the V-shaped corrugated paper core 2', the structure can weaken the force in the vertical direction when it is impacted by an external force, so it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| edge compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| edge compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com