A Special Comprehensive Finishing Broach for Improving the Machining Quality of Ultra-Large Tenon and Groove of Fan Disk

A technology of processing quality and fine broaching, which is applied in broaching tools, metal processing equipment, broaching machines, etc., can solve problems such as non-smooth transfer of tenon-groove profiles, affecting the processing quality of parts, and large tenon and groove of fan discs, etc., to achieve Avoid the phenomenon of non-smooth transfer, high pass rate, and avoid the effect of connecting knife marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

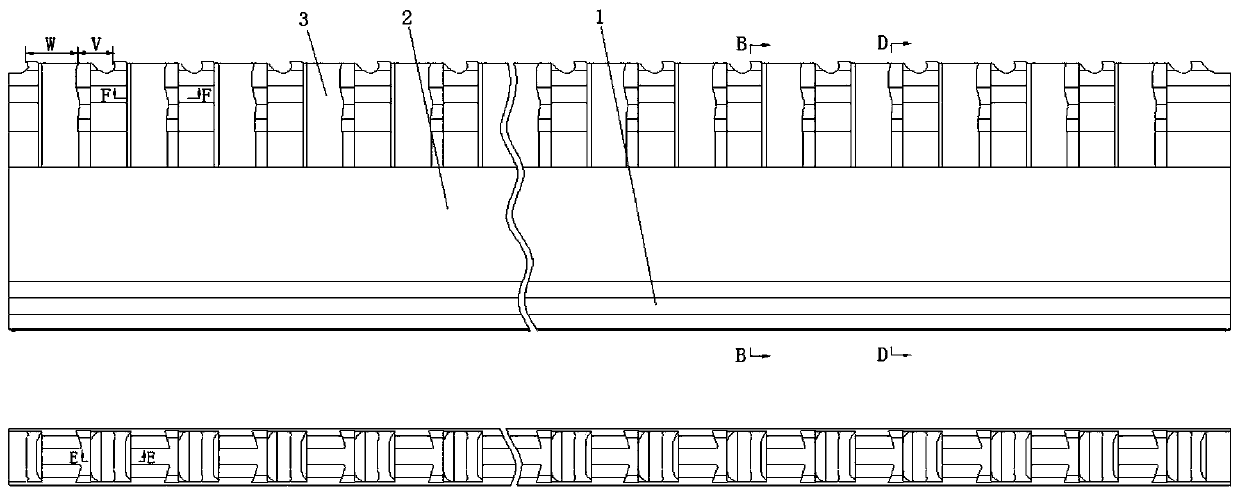

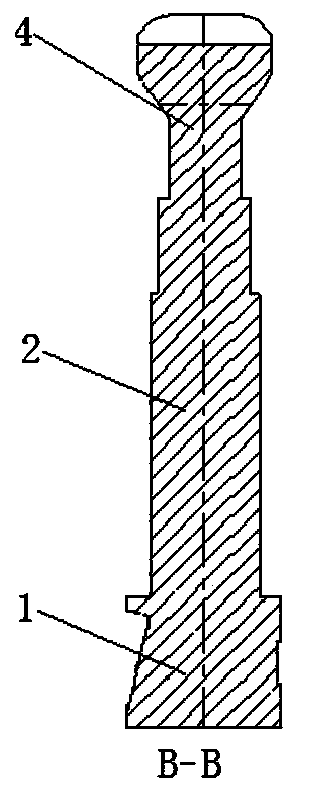

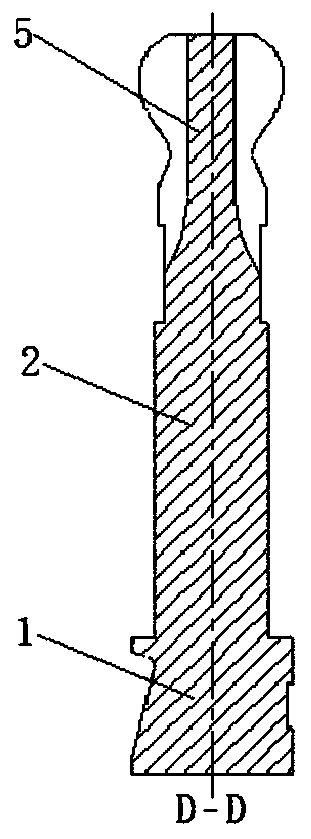

[0020] like Figure 1-Figure 5 As described above, a special comprehensive finishing broach for improving the processing quality of super large mortise grooves of fan disks, the comprehensive finishing broach is composed of three parts: the connecting part of the tool holder 1, the neck of the broach 2 and the teeth 3 from bottom to top. The connecting part 1 of the tool holder is connected to the high-speed broaching machine tool box through a pressing block, and the knife teeth 3 are composed of odd-numbered knife teeth 4 and even-numbered knife teeth 5, and the odd-numbered knife teeth 4 and the even-numbered knife teeth 5 are arranged alternately, and the odd-numbered knife teeth Teeth 4 and even teeth 5 are alternately arranged to form wheel cutting for the entire tongue-and-groove profile, so as to reduce the cutting area. The role of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com