Pipe bending neutral layer offset position determining method

A technology for determining the method and offset position, which is applied in the field of plastic forming of metal materials, can solve problems such as the difficulty in determining the offset of the neutral layer, and achieve the effect of improving the forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

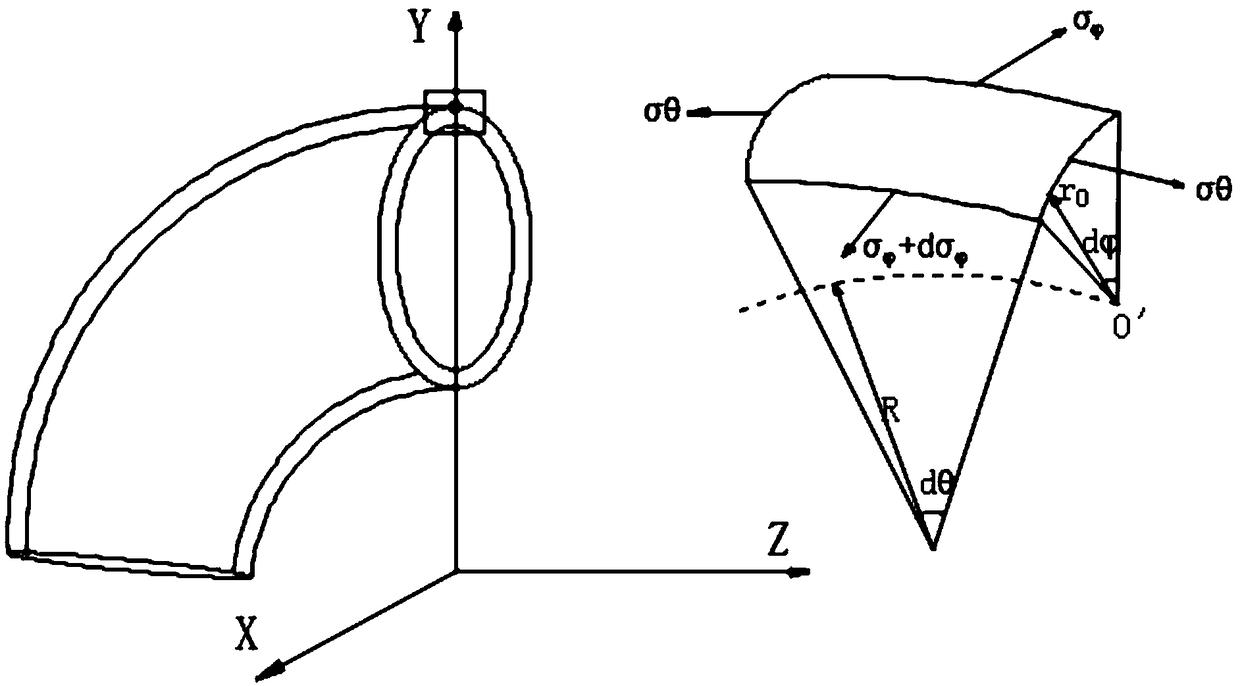

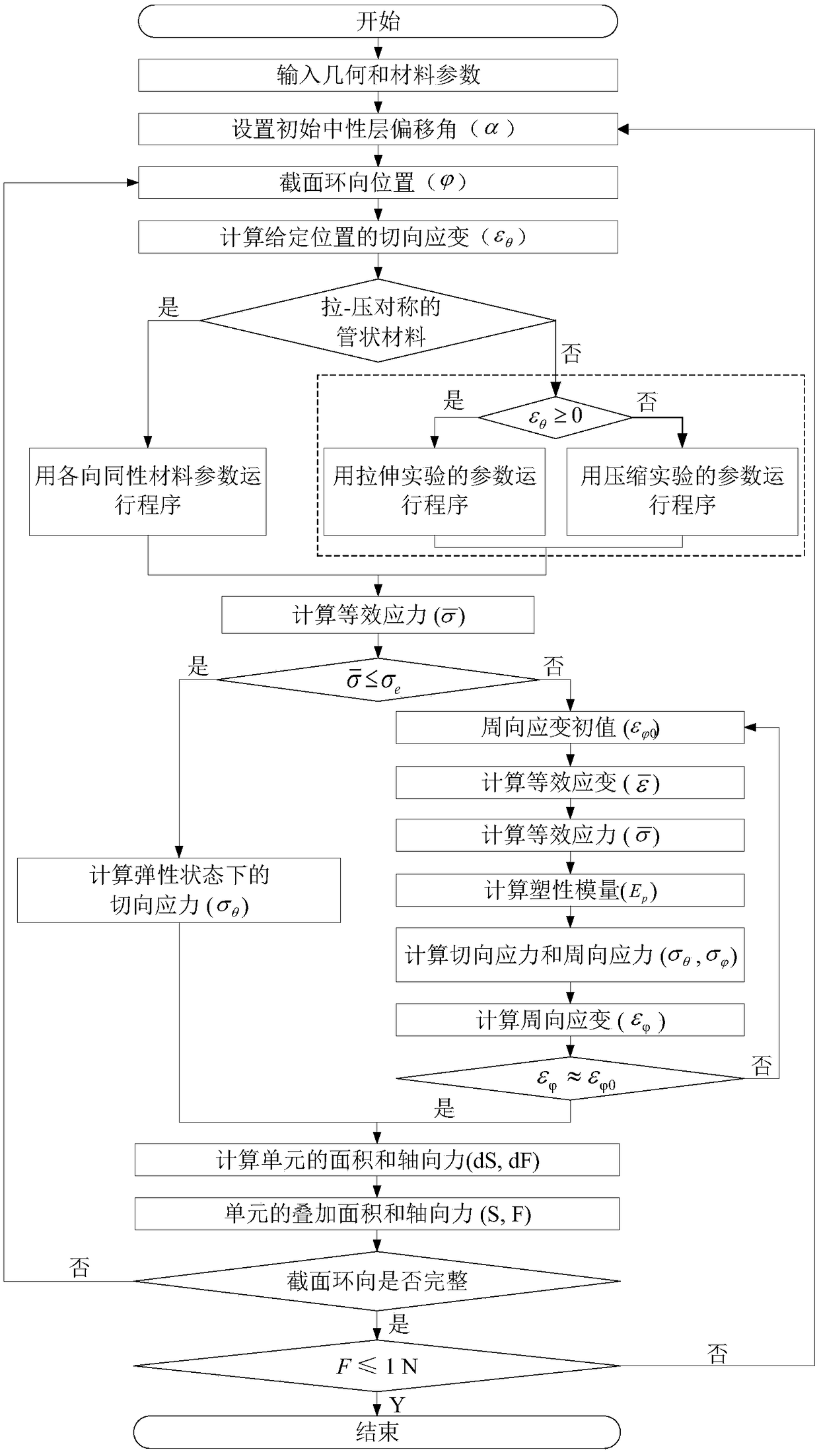

[0066] Such as figure 1 , figure 2 As shown, a method for determining the offset position of the neutral layer in pipe bending includes the following steps:

[0067] Step 1: Static Stress Balance Analysis

[0068] In the section of the bent pipe, X is the geometric central axis, which coincides with the neutral layer before the pipe is bent, Y represents the direction of the bending radius, and the positive direction points to the outer arc of the bend, R is the bending radius, and ρ is the distance between the neutral layer and the bending center. The distance between, y is the distance between the X-axis on the cross-section and any fiber layer, is the calculated angle from any element to the Y axis and any point on the cross section, α is the offset angle of the neutral layer, r 0 is the original radius of the pipe, therefore, the neutral layer offset e can be expressed as

[0069] e=r 0 sinα (1)

[0070] By analyzing a small unit of the bent pipe, the stress state ...

Embodiment 2

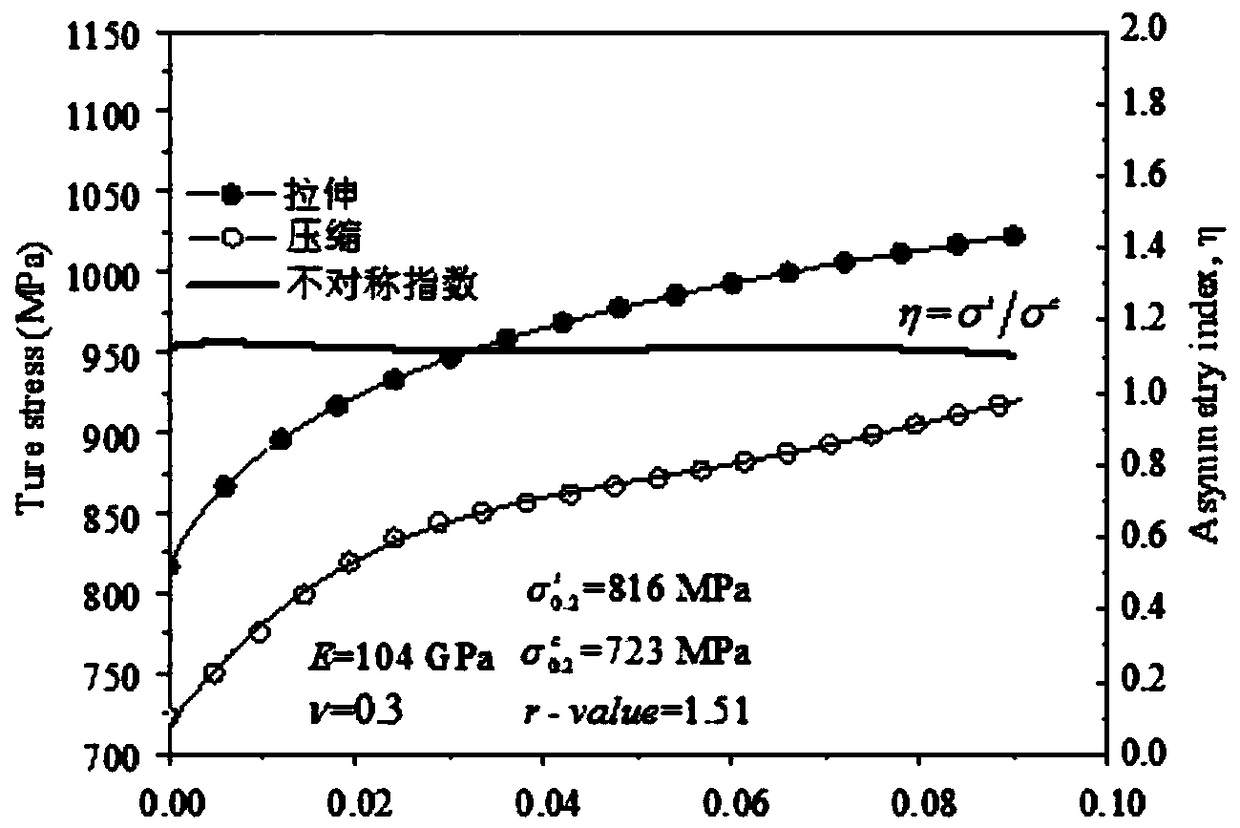

[0115] Such as Figure 3 to Figure 5 As shown, this embodiment 2 is a calculation method for the offset position of the neutral layer in the numerically controlled bending (RDB) of pipes. In Example 2, Ti-3Al-2.5V titanium alloy pipe is selected as the curved pipe, and its specification is Φ12×t0.9mm (pipe outer diameter×wall thickness), which has obvious anisotropy and tension-compression asymmetry . The material properties of the pipes are obtained by uniaxial tensile and compression tests, see image 3 . Introduce an asymmetry index (η) to describe the level of transient tension-compression asymmetric behavior, by η=σ t / σ c Definition, its value is about 1.1. In order to introduce the asymmetric behavior into the mixed neutral layer migration framework, the tensile and compressive stress-strain relationships were fitted by Swift and Shah functions, respectively. The fitting equation is represented by formula (19)

[0116]

[0117] σ is the equivalent stress, an...

Embodiment 3

[0123] Such as Figure 6 , Figure 7As shown, in order to further evaluate the hybrid NLS model, AZ31 pipe and A6063 pipe were used for press bending (PB). The schematic diagram of press bending is shown in Figure 6 As shown, the tooling includes a punch 1, a pipe 2, a support plate 3 and a lower die 4. The specifications of the two pipes are Φ25×t1.5mm. The AZ31 pipe has strong anisotropy, and the A6063 shows a very low tension-compression Asymmetry and thus can be considered a symmetrical material.

[0124] First, the material properties of the pipe are obtained, through the tensile-compression test, the results are as follows Figure 7 , the asymmetry index of the A6063 pipe is about 1.0, which does not change much with the plastic strain; the index of the AZ31 pipe varies greatly, from 0.7 to 1.6, increases in the initial small strain range, and then shows an exponential decay trend. The asymmetric behavior of the AZ31 tube undergoes a complex evolution during plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com