Grinding host discharging and screening mechanism

A screening machine and material screen technology, applied in grain processing and other directions, can solve the problems of fixed screen holes, easy blockage, low screening efficiency, etc., and achieve the effect of improving screening efficiency, reducing maintenance time and cost, and improving raw material processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

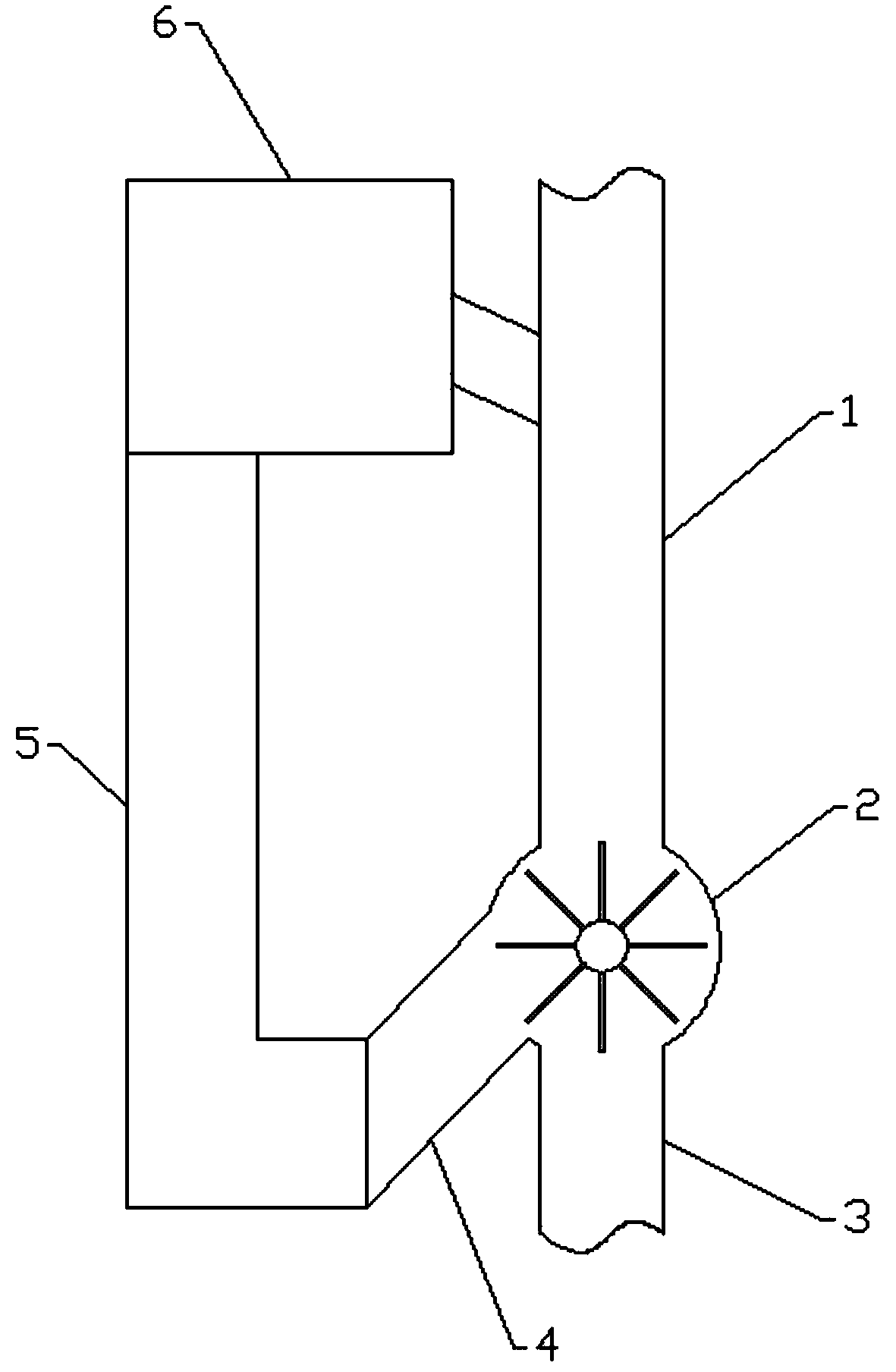

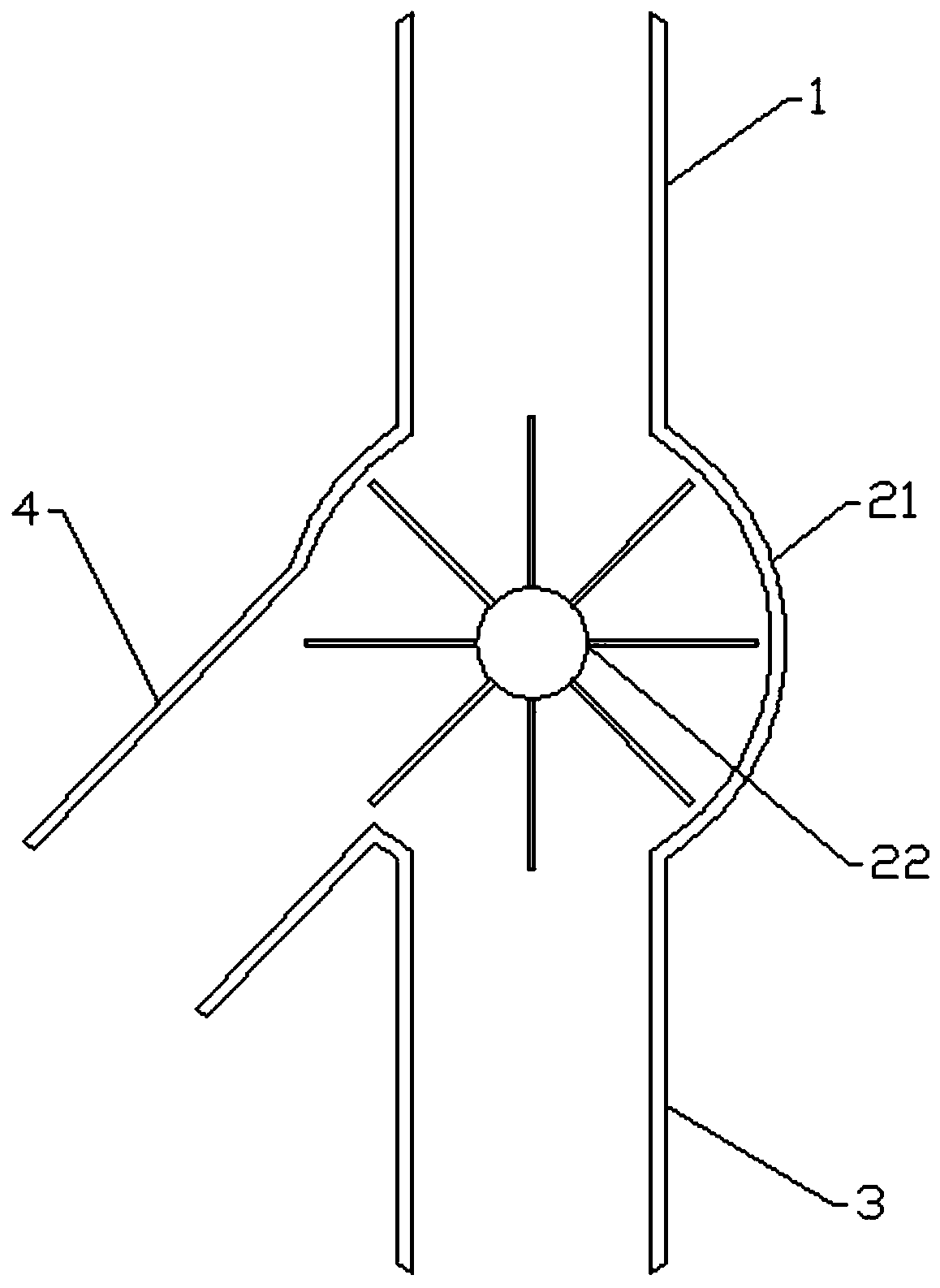

[0018] Such as Figure 1-3 As shown, the present invention proposes a discharging and screening mechanism for a grinding host, which includes a feeding pipe 1, a screening machine 2 and a discharging pipe 3 arranged from top to bottom, wherein the upper and lower ends of the screening machine 2 are open and the feed The pipe 1 and the discharging pipe 3 are connected. In this embodiment, the feeding pipe 1 and the discharging pipe 3 are arranged collinearly, so that the upper and lower ends of the screening machine 2 are arranged oppositely, and the raw materials can fall in the vertical direction without slipping and skewing To other places.

[0019] In the present invention, the side of the screening machine 2 is also provided with a downwardly inclined return pipe 4. In a preferred solution, the included angle between the return pipe 4 and the discharge pipe 3 is 30-60°, and in this embodiment, it is 45°. To return the unqualified raw materials. The present invention also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com