Flue gas ultra-clean treatment system based on particle chemical agglomeration and cloth bag dust removal

A technology of chemical agglomeration and bag dust removal, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of large floor area, large equipment volume, reducing the speed of flue gas, that is, the filtering wind speed, etc., to achieve operational use Convenient, reasonable design, small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

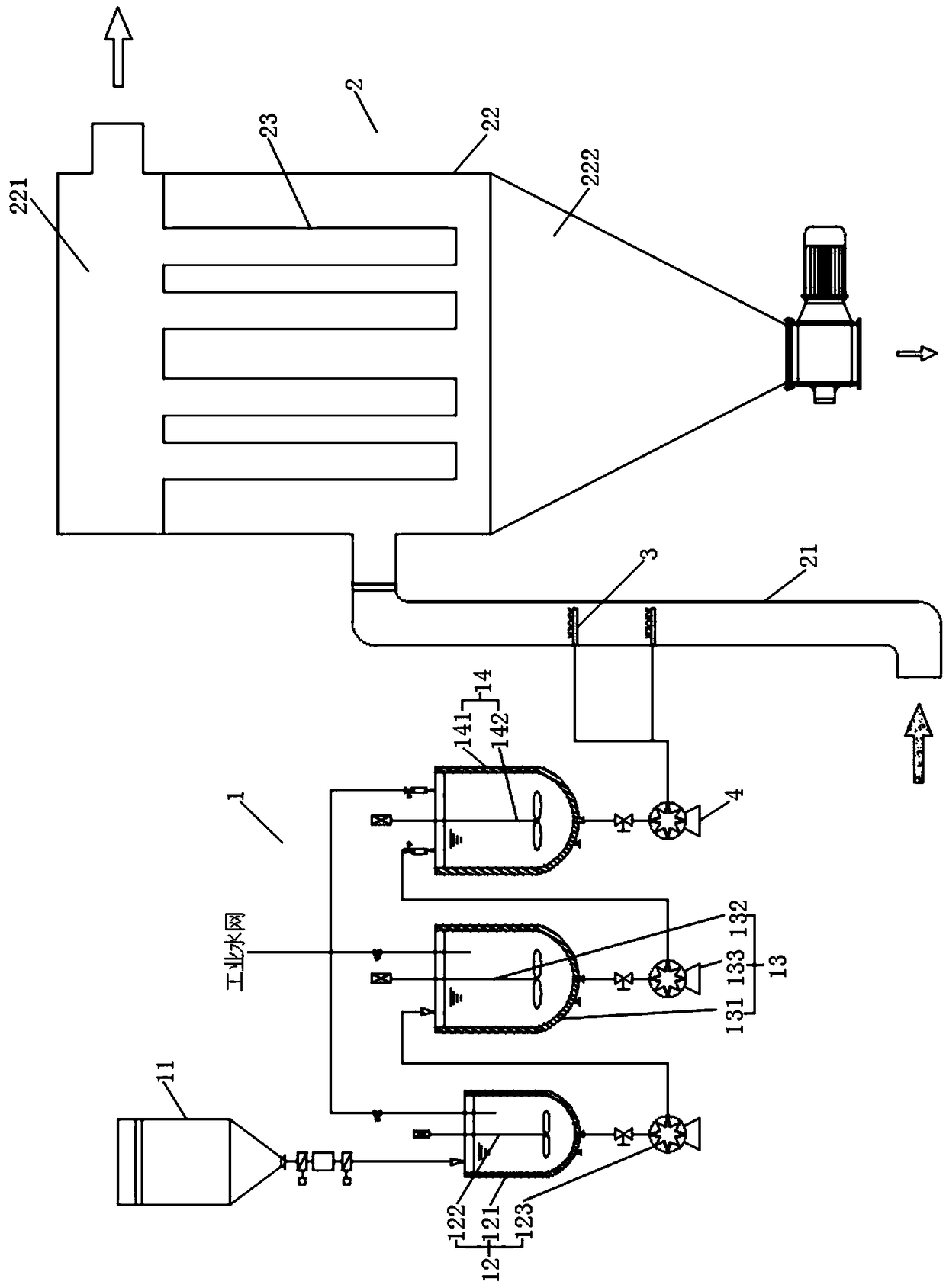

[0035] Example: such as figure 1 As shown, the flue gas ultra-clean treatment system based on the chemical agglomeration of particulate matter and bag dust removal in this embodiment includes agglomeration liquid deployment and generation equipment 1, bag filter 2 and atomization spray device 3;

[0036] The discharge port of the above-mentioned agglomeration liquid preparation and generating equipment 1 is connected with the above-mentioned atomizing spray device 3 through a delivery pipe, and a first power delivery device 4 is arranged on the delivery pipe;

[0037] The above-mentioned atomizing spray device 3 is installed in the inlet flue 21 of the above-mentioned bag filter 2, and is used to spray the agglomeration liquid in the flue gas flowing through the above-mentioned inlet flue 21 to chemically agglomerate the fine particles in the flue gas. Large particles.

[0038] During the dust removal process, the agglomeration liquid preparation and generation equipment 1 ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com