A processing system for compound oil

A processing system and compound oil technology, applied in application, food science, food processing, etc., can solve the problems of loss of raw materials, crushed sesame nutrients, waste, etc., and achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

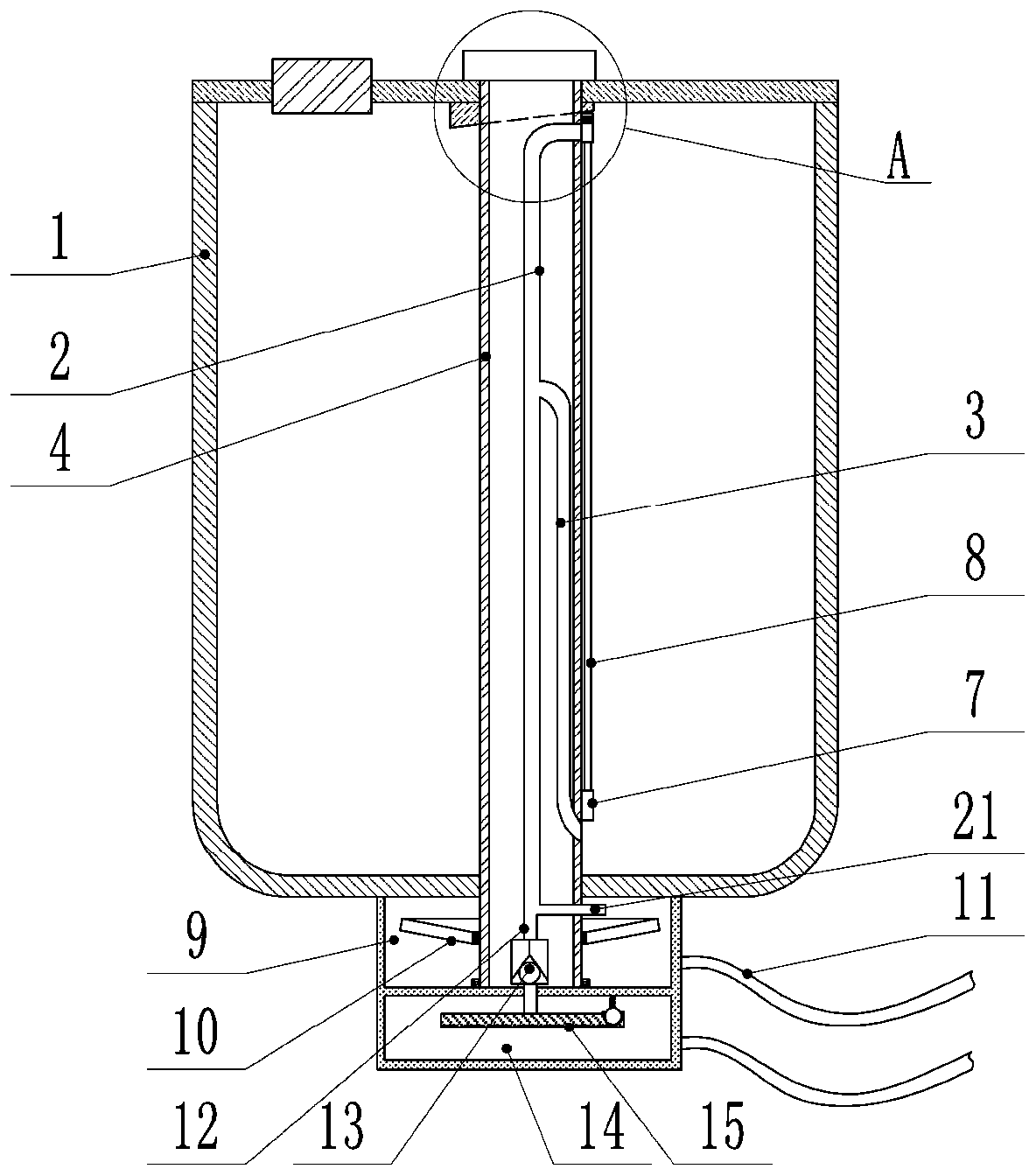

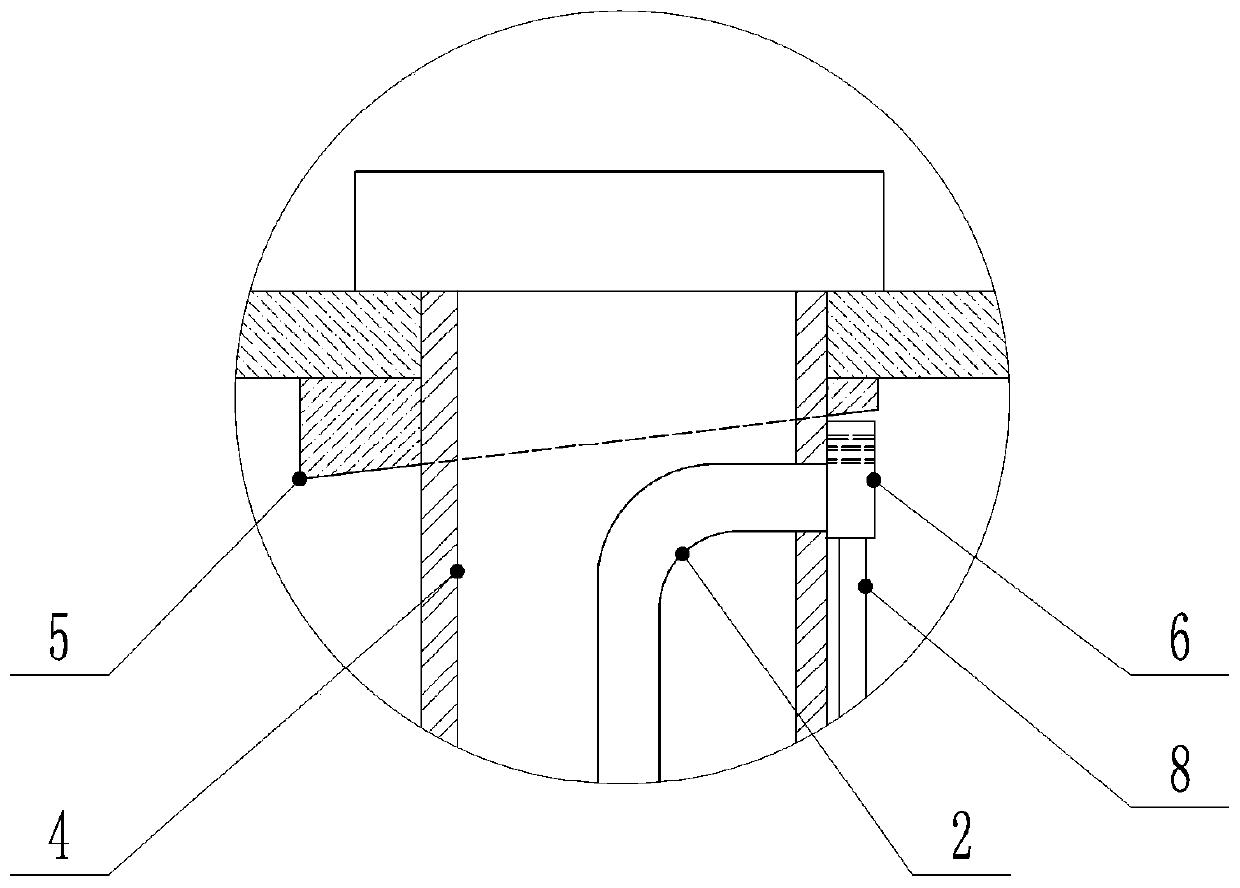

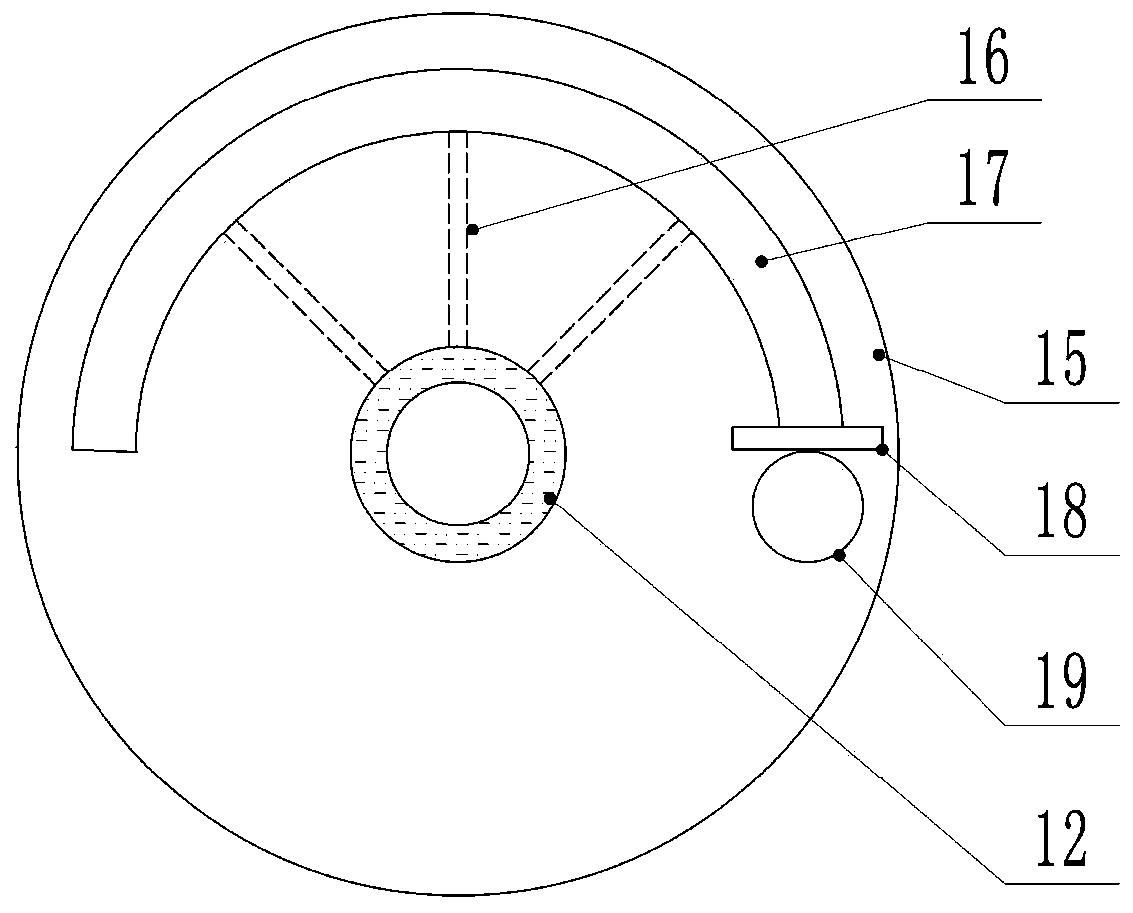

[0021] The reference signs in the drawings of the description include: cleaning box 1, upper cleaning pipe 2, lower cleaning pipe 3, rotating shaft 4, cylindrical cam 5, upper slider 6, lower slider 7, connecting rod 8, water inlet tank 9, Turbine 10, water inlet pipe 11, airflow pipe 12, one-way valve 13, air box 14, rotating disk 15, air duct 16, chute 17, moving block 18, hanging ball 19, elastic cloth 20, connecting pipe 21.

[0022] Example figure 1 Shown: a compound oil processing system, including a cleaning box 1, the top of the cleaning box 1 is provided with a cover plate, and the cover plate is provided with a feeding port. The cleaning box 1 is provided with a vertically arranged rotating shaft 4 with a hollow interior, and the upper end of the rotating shaft 4 is fixed on the cover plate by a block and can rotate on the cover plate. The side wall of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com