Method for reducing color and luster changes of low-temperature cooked meat product during vacuum pre-cooling process

A low-temperature, cooked meat technology, applied in the direction of food ingredients as color, food science, etc., can solve the problems of sample L* value increase, a* value decrease, etc., to achieve the effect of reducing water loss, reducing water loss, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

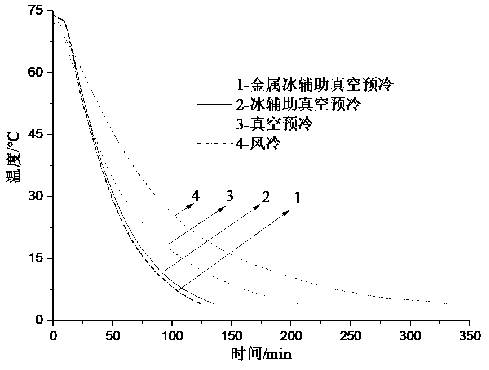

Image

Examples

Embodiment 1

[0028] The vacuum pre-cooler used in the present invention is KM-100 equipment (experimental small-scale vacuum pre-cooler). The vacuum pre-cooler mainly includes a vacuum box, a condenser, a vacuum pump, and an operation interface, among which the operation interface can control the opening of the pipeline valve. Size, vacuum pump on and off, condenser on and off, drain valve on and off.

[0029] The pressure drop rate coefficient used in the present invention is by formula Sure. in, P is the Jedi pressure in the vacuum chamber of the vacuum pre-cooler during operation, in mbar; P i is the local atmospheric pressure, the unit is mbar; t is the pumping time of the vacuum box, the unit is min; Y is the rate of pressure drop, in min -1 ; Calculate the pressure drop rate by taking the time t it takes for the local atmospheric pressure to drop from 1000 mbar to the Jedi pressure of 6.5 mbar Y value. Pressure drop rate coefficient Y Indicates the speed of the pressure drop...

Embodiment 2

[0046] Cook the prepared ham sausage (porosity 0.86%, diameter 55mm, height 500mm) to make its center temperature 72°C, take out and remove its packaging material, and then wrap the ham sausage with two layers of sterilized wet gauze. Other modes of operation are the same as in Example 1. The results are shown in Table 3 and Table 4 below.

[0047] Table 3 The results of different pre-cooling methods on the pre-cooling time and water loss of ham sausage

[0048]

[0049] It is not difficult to find that the results presented in Table 3 are similar to the results in Table 1 in Example 1, and the metal ice-assisted vacuum precooling can obtain lower precooling time and moisture loss rate.

[0050] Table 4 Effects of different precooling methods on the color of ham sausage after precooling

[0051]

[0052] Remarks: L*: means black and white, the larger the value is, the whiter the color; a*: means red-green, + means reddish, - means greenish; b*: means yellow-blue, + mea...

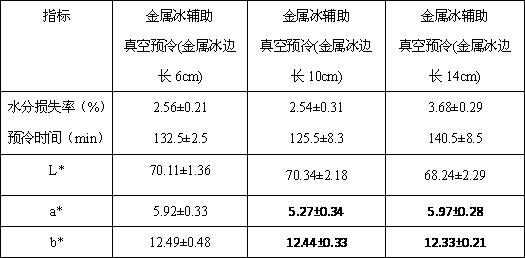

Embodiment 3

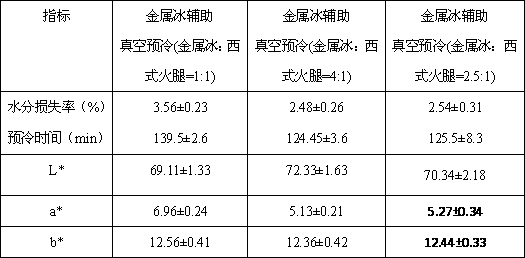

[0056] The operation method of embodiment 3 is the same as that of embodiment 1, the difference is the amount of metal ice added, in order to form a comparison and determine the best ratio, we have chosen the ratio of metal ice to Western-style ham to be 1:1 and 4:1 respectively. For comparison, the results are shown in Table 5: Although the addition of metal ice can effectively reduce the water loss rate and reduce the pre-cooling time, the more the better, when the increase reaches 4:1, it is the same as the specific implementation of this patent Example (2.5:1) obtained similar results. Of course, it is well known that the increase of metal ice will also increase the corresponding cost. The above results show that the specific weight ratio of metal ice and Western-style ham selected in the patent scope can effectively reduce the moisture loss rate, pre-cooling time and color effect of Western-style ham.

[0057] Table 5 Effects of different metal ice additions on moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com