Light emitting diode and preparation method thereof, and application thereof

A technology of light-emitting diodes and light-emitting layers, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electric solid-state devices. Effects of light extraction efficiency, increase in electrical stability and mechanical stability, and guaranteed life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (2) Preparation method of light-emitting diodes

[0035] On the other hand, on the basis of the above-mentioned light-emitting diodes, embodiments of the present invention also provide a method for preparing the above-mentioned light-emitting diodes. combine figure 1 , 2 , the preparation method of the above light-emitting diode can be prepared according to the following method:

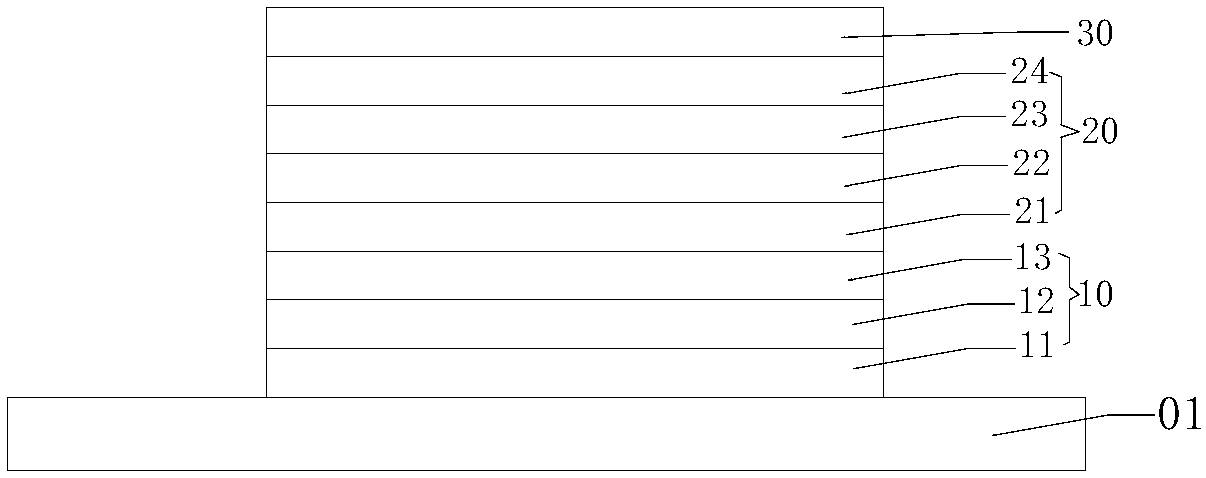

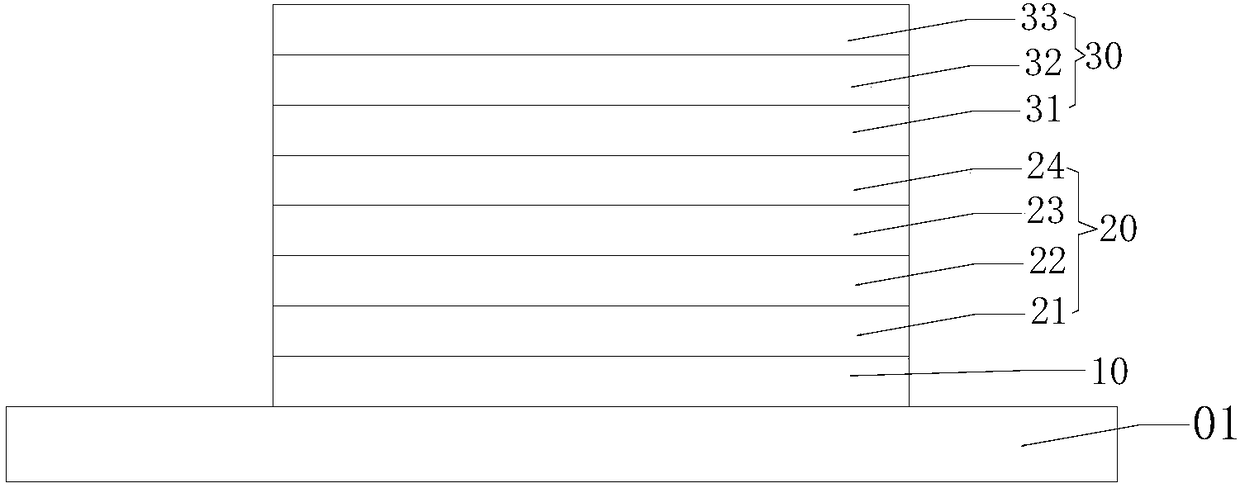

[0036] An embodiment, when the light emitting diode structure is such as figure 1 When shown, include the following steps:

[0037] Step S01. Deposit an interlayer composite anode 10 on the surface of the base layer 01: deposit a first metal oxide layer 11 and a graphene layer 12 on the surface of the base layer 01, and deposit a second metal oxide on the surface of the graphene layer 12 after annealing layer 13;

[0038] Step S02. Prepare the light-emitting unit 20 and the cathode 30 sequentially on the outer surface of the anode 10: sequentially deposit the surface of the second metal o...

Embodiment 1

[0057] In this embodiment, the compound anode light-emitting diode includes a structure such as figure 1 shown, including sequentially bonded glass / MoO 3 (20nm) / Graphene(80nm) / MoO 3 (20nm) / PEDOT:PSS(40nm) / TFB(50nm) / quantum dot light-emitting layer(70nm) / ZnO(40nm) / Al(100nm).

[0058] The light-emitting diode of this embodiment is prepared according to the following method:

[0059] S11: Place the glass substrate 0 in acetone, washing solution, deionized water and isopropanol in sequence for ultrasonic cleaning, and each step of ultrasonic cleaning needs to last for about 15 minutes. After the ultrasound is completed, place the substrate in a clean oven to dry for later use;

[0060] S12: After the substrate is dried, deposit a layer of MoO on it 3 Metal oxide 11, then, deposit a layer of graphene layer 12 on it, put it on the heating stage of 150 ℃ and heat for 15min, after the above-mentioned substrate includes the layer of graphene cooling, deposit a layer of graphene on ...

Embodiment 2

[0064] In this embodiment, the compound anode light-emitting diode includes a structure such as figure 1 shown, including sequentially bonded glass / MoO 3 (50nm) / Graphene(50nm) / WO 3 (10nm) / TFB(80nm) / quantum dot light-emitting layer (40nm) / ZnO(40nm) / Al(100nm).

[0065] The light-emitting diode of this embodiment refers to the preparation method of Embodiment 1 according to the following method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com