Preparation method of Al-Nb-B alloy rod for grain refinement

A technology of grain refinement and grain refiner, which is applied in the field of preparation of metal grain refiner and refiner for aluminum-silicon alloy, can solve the problems of failure to meet the expectations of aluminum casting manufacturers, poor anti-recession performance, Low refinement efficiency and other problems, to achieve the effect of improved particle agglomeration, strong anti-fading performance, and improved refinement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

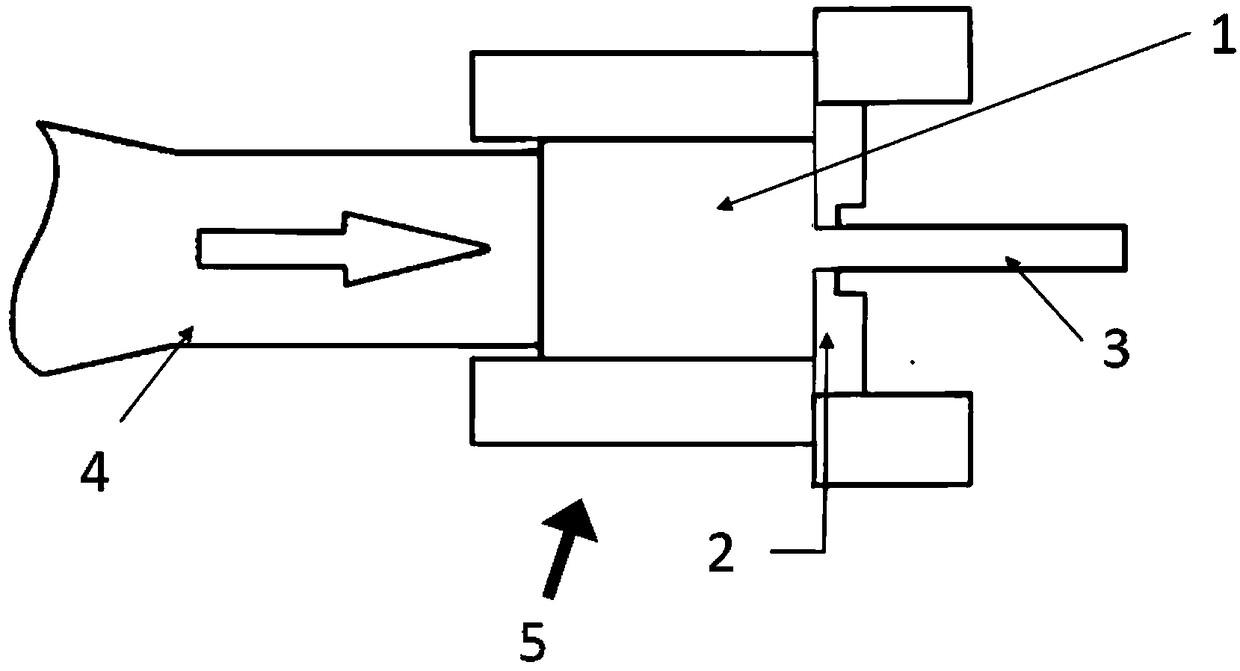

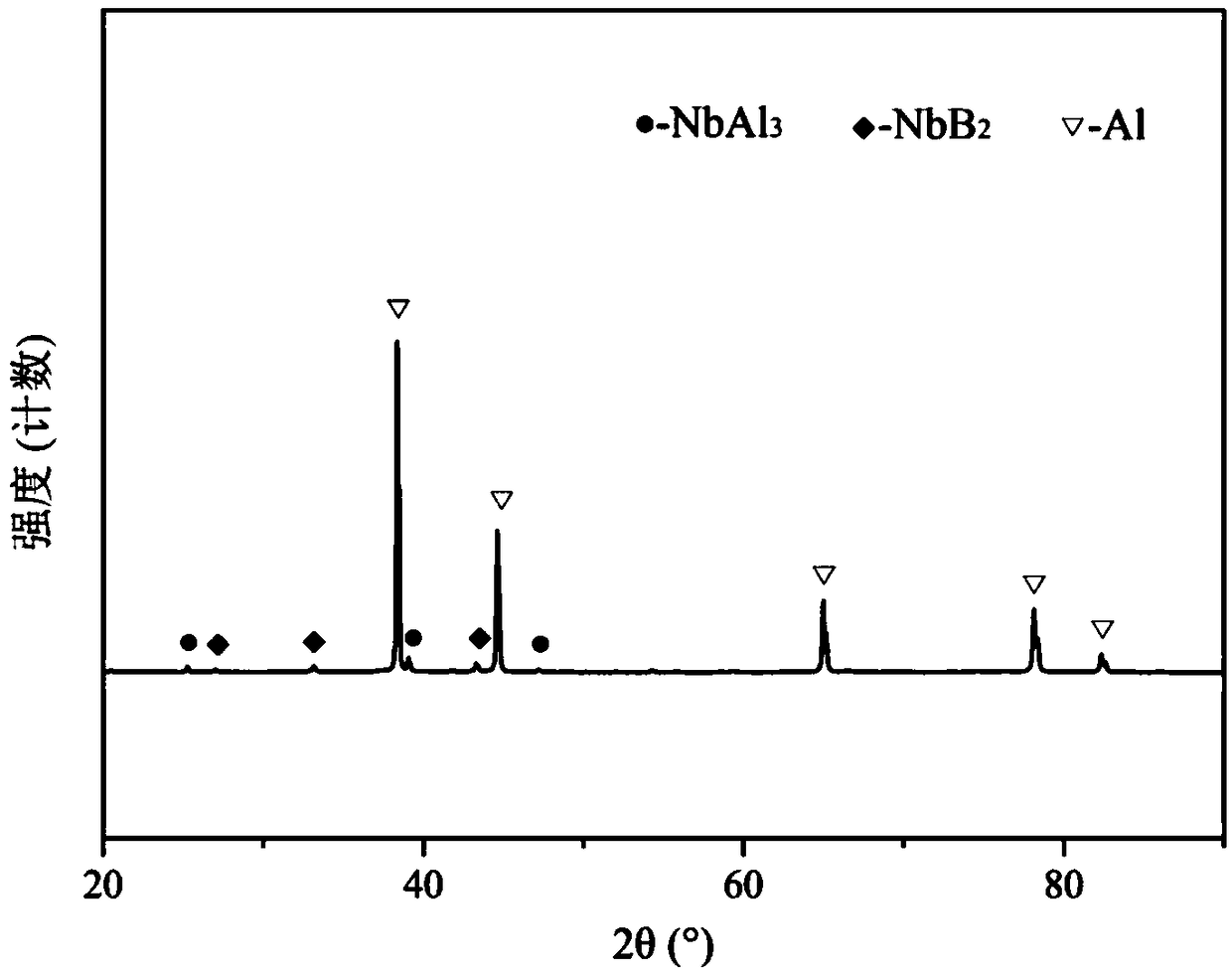

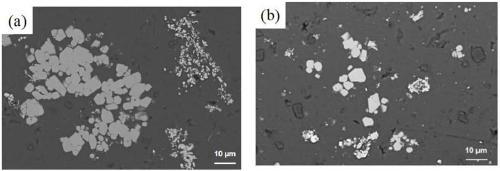

[0032] In this example, see Figure 1 to Figure 5 , a method for preparing aluminum-niobium-boron alloy rods for grain refinement. The alloy is smelted by a fluoride-salt reaction method, directly cast into shape, and then hot-extruded from an aluminum-niobium-boron ingot to form an aluminum-niobium-boron alloy rod as an aluminum alloy Grain refiner material, the steps of the preparation method of the aluminum-niobium-boron alloy rod used for grain refinement are as follows:

[0033] a. Material preparation: Potassium fluoroborate KBF 4 As the B source material, aluminum block, niobium powder and potassium fluoroborate were respectively weighed as raw materials, and the raw materials were weighed and proportioned according to the following mass fractions:

[0034] 2.8wt.% Nb, 0.3wt.% B, the balance is Al;

[0035] b. Melting the Al ingot: heat and melt the aluminum block weighed in the step a, and keep it at 850°C for 30 minutes to make the chemical composition of the alumin...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, especially in that:

[0047] In this example, a method for preparing an aluminum-niobium-boron alloy rod for grain refinement uses a fluorine-salt reaction method to smelt the alloy, directly casts it into shape, and then hot-extrudes the aluminum-niobium-boron alloy rod from an aluminum-niobium-boron ingot The alloy rod is used as an aluminum alloy grain refiner material, and the steps of the preparation method of an aluminum-niobium-boron alloy rod for grain refinement are as follows:

[0048] a. Material preparation: Potassium fluoroborate KBF 4 As the B source material, aluminum block, niobium powder and potassium fluoroborate were respectively weighed as raw materials, and the raw materials were weighed and proportioned according to the following mass fractions:

[0049] 3.5wt.% Nb, 0.5wt.% B, the balance is Al;

[0050] b. Melting the Al ingot: heat and melt the aluminum block weighed in the step a, and keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com