A kind of high-hardness wear-resistant water-based baking varnish and preparation method thereof

A high-hardness, water-based technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of insufficient performance of potassium hexatitanate whisker enhancement and friction resistance. Achieve the effect of improving compatibility and combination, improving hardness and wear resistance, and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

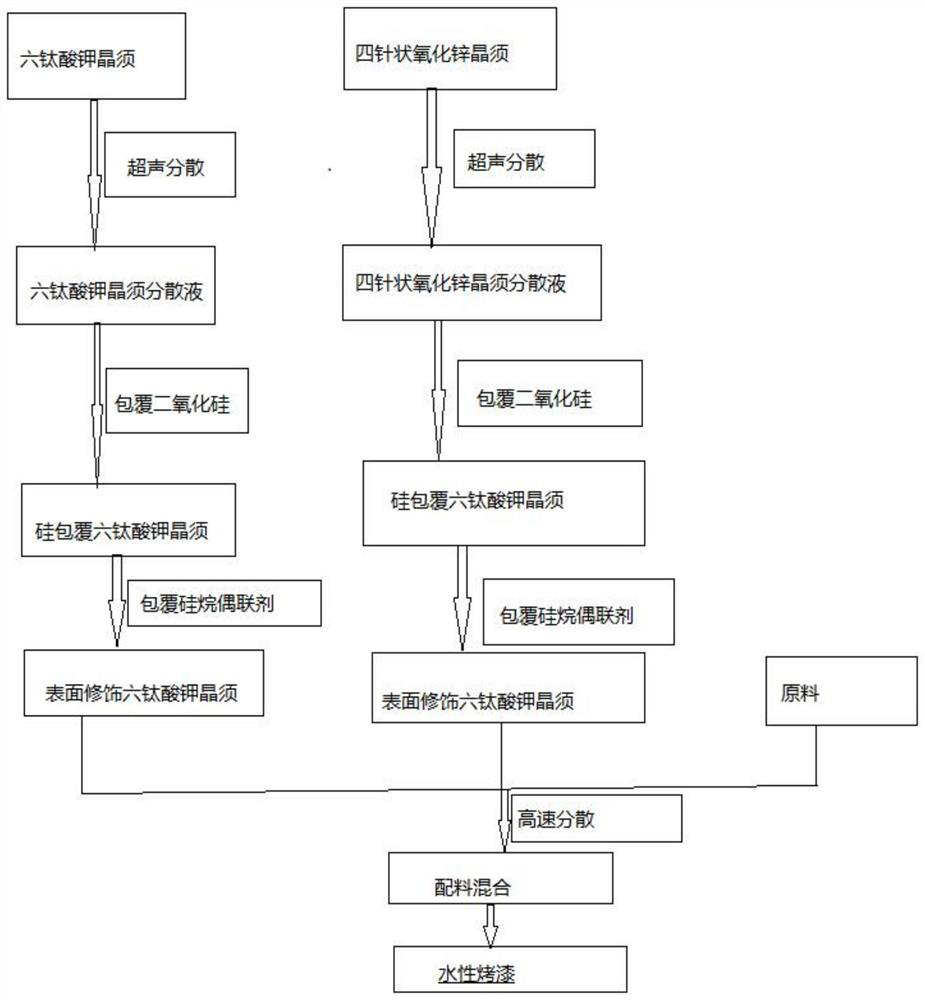

Method used

Image

Examples

Embodiment 1

[0027] Raw material preparation: surface modified whiskers are prepared by the following method, surface modified whiskers are surface modified tetrapod-shaped zinc oxide whiskers, surface modified potassium hexatitanate whiskers, wherein the preparation of surface modified tetrapod-shaped zinc oxide whiskers Including: (1) Coating of tetraacicular zinc oxide whiskers: Accurately weigh 9 grams of tetraacicular zinc oxide whisker powder and disperse in 100 ml of deionized water, ultrasonically disperse for 30 minutes to obtain tetraacicular zinc oxide Whisker dispersion; (2) transfer the four-needle zinc oxide whisker dispersion to a constant temperature water bath of 80°C, slowly add 0.1mol / L Na2SiO3 solution 167 milliliters dropwise under uniform stirring, and use 1%wt H2SO4 solution to adjust the pH of the solution, control the pH of the solution to be 9-10, and after 2 hours of heat preservation and aging, filter, wash, and dry to obtain silicon-coated four-acicular zinc oxi...

Embodiment 2

[0030] Raw material preparation: surface modified whiskers are prepared by the following method, surface modified whiskers are surface modified tetrapod-shaped zinc oxide whiskers, surface modified potassium hexatitanate whiskers, wherein the preparation of surface modified tetrapod-shaped zinc oxide whiskers include:

[0031] (1) Coating of tetraacicular zinc oxide whiskers: Accurately weigh 10 grams of tetraacicular zinc oxide whisker powder and disperse in 100 ml of deionized water, and ultrasonically disperse for 30 minutes to obtain tetraacicular zinc oxide whiskers Dispersion solution; (2) transfer the four-needle zinc oxide whisker dispersion solution to a constant temperature water bath of 80°C, slowly add 0.1mol / L Na2SiO3 solution 180 milliliters dropwise under uniform stirring, and adjust the solution with 1wt% H2SO4 solution The pH value of the control solution is 9-10. After heat preservation and aging for 2 hours, filter, wash, and dry to obtain silicon-coated te...

Embodiment 3

[0034] Raw material preparation: surface modified whiskers are prepared by the following method, surface modified whiskers are surface modified tetrapod-shaped zinc oxide whiskers, surface modified potassium hexatitanate whiskers, wherein the preparation of surface modified tetrapod-shaped zinc oxide whiskers Including: (1) Coating of tetraacicular zinc oxide whiskers: Accurately weigh 10 grams of tetraacicular zinc oxide whisker powder and disperse in 100 ml of deionized water, ultrasonically disperse for 30 minutes to obtain tetraacicular zinc oxide Whisker dispersion; (2) transfer the four-needle zinc oxide whisker dispersion to a constant temperature water bath of 80°C, slowly add 0.1mol / L Na2SiO3 solution 167 milliliters dropwise under uniform stirring, and use 1wt% H2SO4 solution Regulate the pH of the solution, control the pH of the solution to be 9-10, and then filter, wash and dry the solution to obtain silicon-coated four-acicular zinc oxide whiskers; (3) accurately w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com