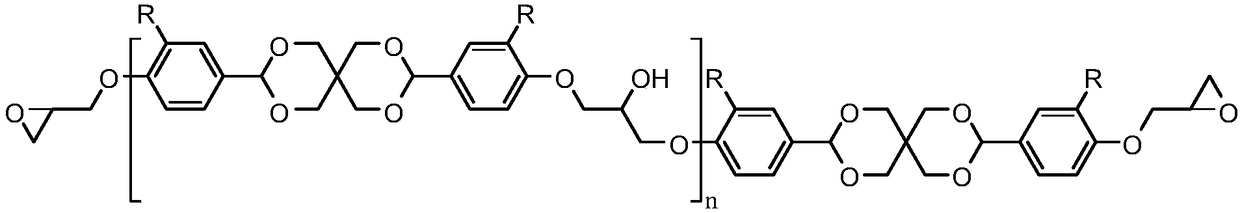

Easily-recoverable carbon fiber composite material based on spiral cyclic acetal epoxy resin

A technology of cyclic acetal epoxy resin and composite materials, which is applied in the field of polymers and composite materials, can solve the problems of removal of small molecule curing shrinkage, mechanical properties, and base composite materials, and is conducive to large-scale industrial production , easy to implement, and highly operable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

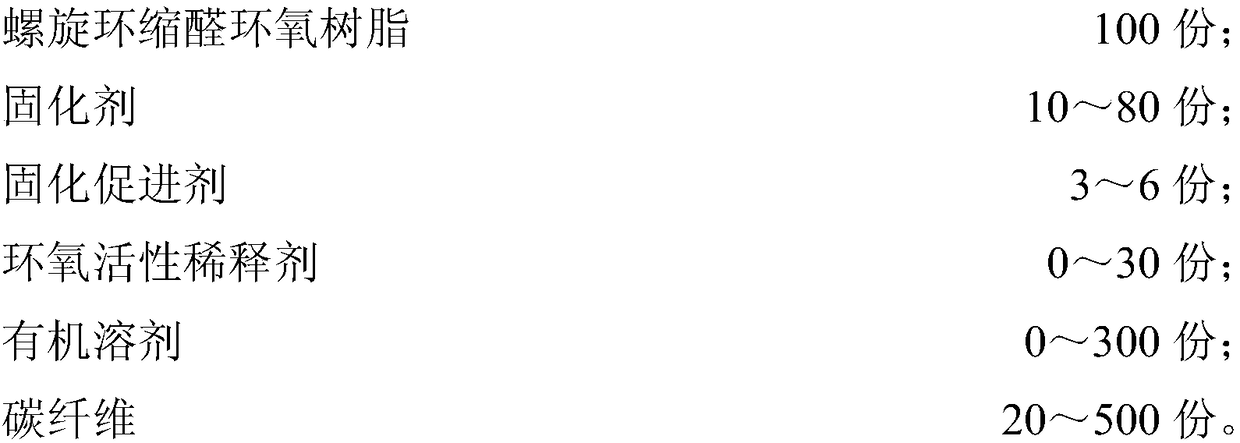

Method used

Image

Examples

Embodiment 1

[0045] Mix and stir 100g of spiral ring acetal epoxy resin 3, 80g of methyl hexahydrophthalic anhydride, and 30g of short carbon fiber evenly, then cure at 120°C for 2 hours, at 160°C for 2 hours, and at 200°C for 2 hours to obtain Carbon fiber composite material.

[0046]The obtained carbon fiber composite material is placed in a mixed solution of 0.1M HCl water and ethanol (water:ethanol volume ratio is 2:8), and it is completely degraded in 3 hours at room temperature. the difference.

Embodiment 2

[0048] Mix 100g of spiral ring acetal epoxy resin 1, 14g of 4,4′-diaminodiphenylmethane, 30g of diglycidyl ether and 20g of short carbon fiber, and then cure at 90°C for 2 hours, and at 150°C for 2 hours hours, and cured at 180°C for 2 hours to obtain a carbon fiber composite material.

[0049] The obtained carbon fiber composite material is placed in a mixed solution of 0.1M HCl water and acetone (water:acetone volume ratio is 1:9), and it is completely degraded at room temperature for 3 hours. the difference.

Embodiment 3

[0051] Mix 100g of spiral ring acetal epoxy resin 2, 5g of polyetheramine D230 and 300g of toluene evenly, and then make a carbon fiber felt prepreg with 50g of carbon fiber felt, which is cured at 160°C for 10 hours by hot pressing, and then heated at 180°C After post-curing for 2 hours, the carbon fiber composite material is obtained.

[0052] The resulting carbon fiber composite was placed in 0.05M H 2 SO 4 In the mixed solution of water and tetrahydrofuran (volume ratio of water: tetrahydrofuran is 2:8), it will be completely degraded at room temperature for 5 hours, and the recycled carbon fiber felt can be obtained after washing, and the appearance is no different from the original carbon fiber felt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com