Dressing device and dressing method of substrate back grinding member

A technology for back grinding and dressing devices, which is applied in the direction of grinding devices, abrasive surface adjustment devices, grinding/polishing safety devices, etc., and can solve the problems of reduced grinding performance and inability to achieve grinding treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

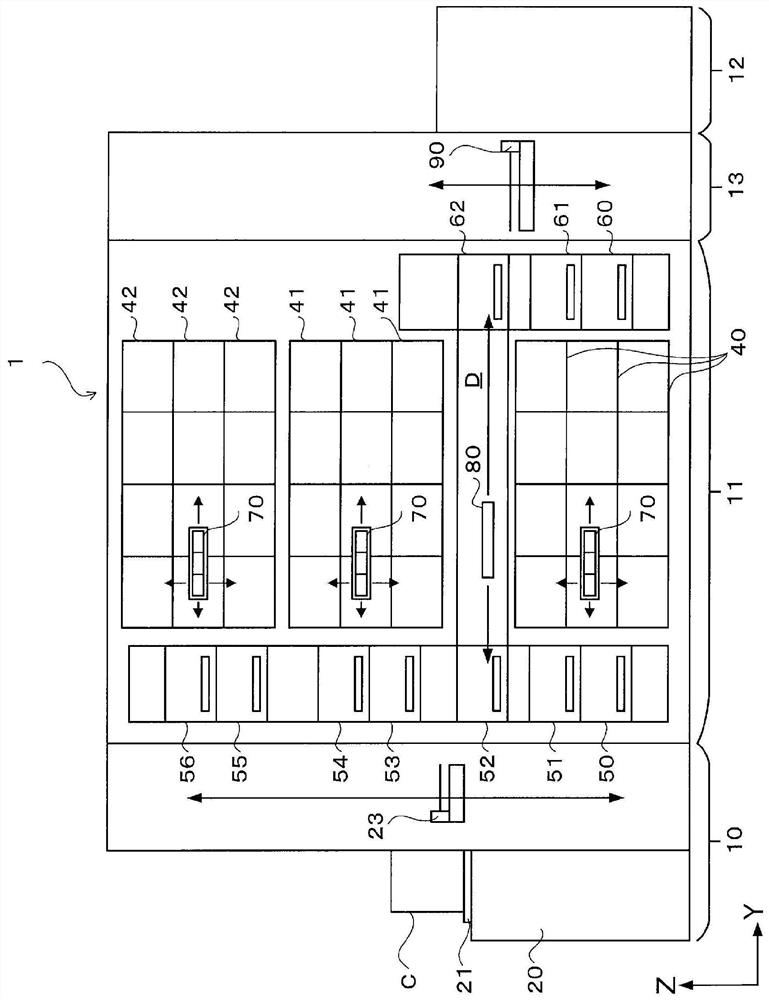

[0059] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the element which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0060]

[0061] First, the configuration of a substrate processing system including the trimming device of the present embodiment will be described. figure 1 It is a schematic plan view schematically showing the configuration of the substrate processing system 1 . figure 2 and image 3 It is a front view and a rear view which schematically show the internal structure of the substrate processing system 1, respectively. In the substrate processing system 1 , predetermined processing is performed on a wafer W as a substrate to be processed.

[0062] Substrate processing system 1 such as figure 1 As shown, it has a structure in which the following parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com