Heating furnace and cleaning method inside the heating furnace

A heating furnace and hearth technology, applied in the field of heating furnace, can solve the problems of reduced operating efficiency, large heat loss, high equipment cost, etc., and achieve the effect of shortening downtime and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

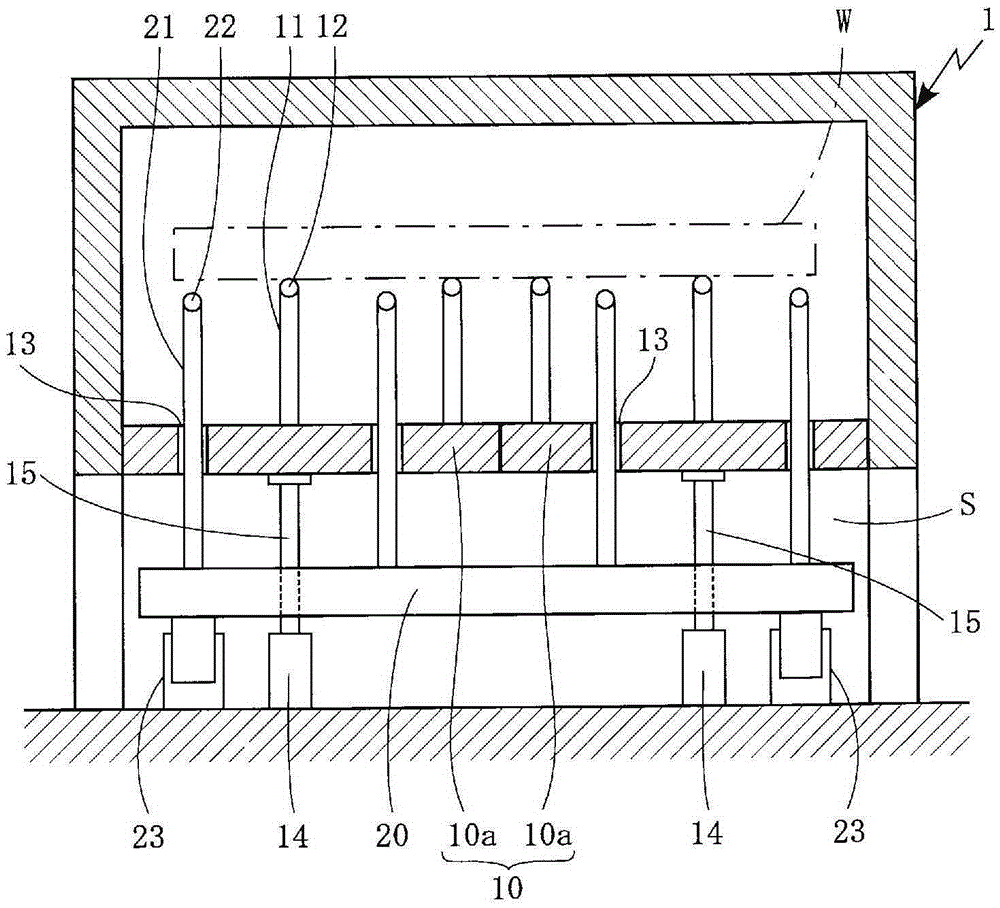

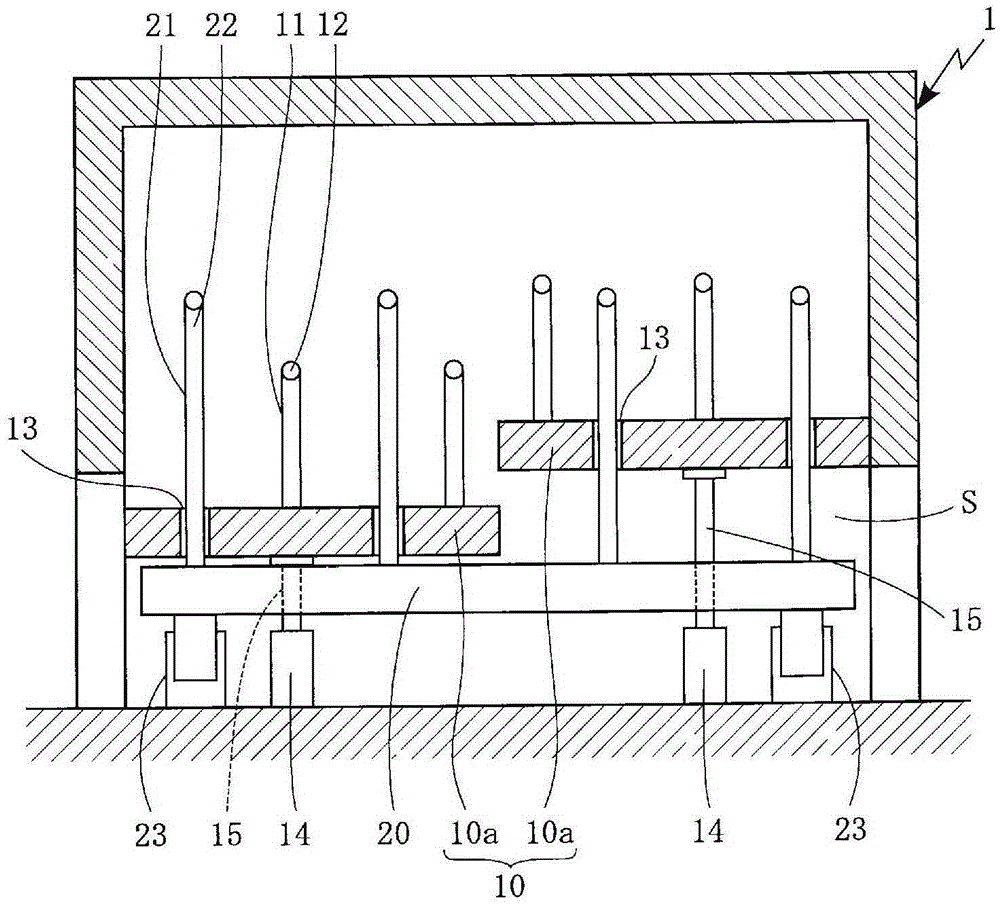

[0030] Hereinafter, a heating furnace according to an embodiment of the present invention and a method of cleaning the inside of the heating furnace will be specifically described with reference to the drawings. In addition, the heating furnace and the cleaning method in the heating furnace of the present invention are not limited to the cases shown in the following embodiments, and can be appropriately changed and implemented within the scope of not changing the idea of the invention.

[0031] In this embodiment, a walking beam type heating furnace is described as an example, but the heating furnace of the present invention is not limited to a walking beam type heating furnace, and can be applied to various types of heating furnaces such as a pusher type.

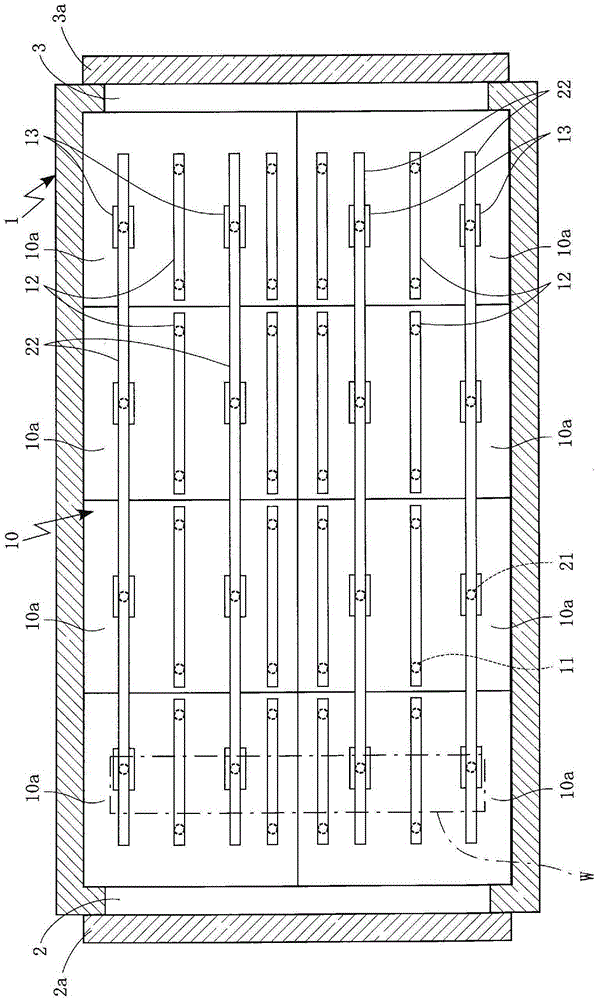

[0032] In the walking beam type heating furnace 1 of this embodiment, as figure 1 and figure 2 As shown, on the hearth 10 provided in the heating furnace 1, a plurality of support members 11 are erected at required int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com