Absorption core body

A technology of absorbent core and absorbent layer, which is applied in the field of hygiene products, can solve the problems of affecting the secondary liquid absorption effect, affecting the wearing comfort, and the core specific surface area is small, so as to avoid the decrease of diffusivity, improve the overall utilization rate, The effect of increasing the number of SAP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

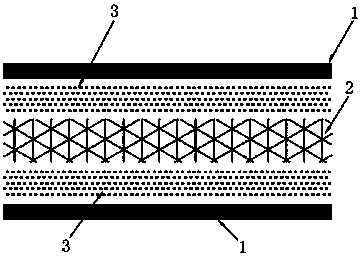

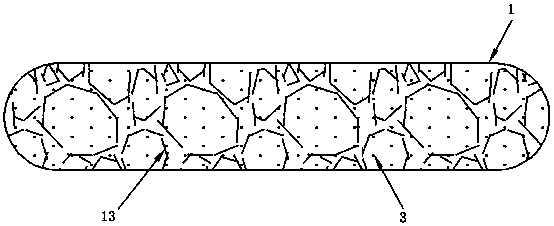

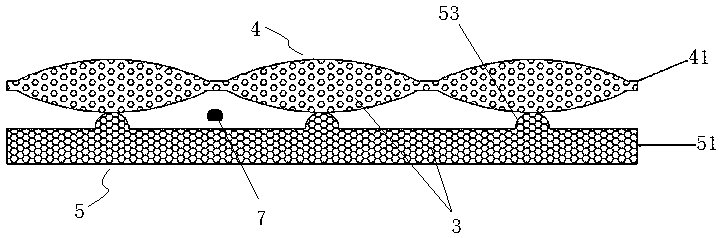

[0047] Such as Figure 3-5 As shown, an absorbent core includes an absorbent layer 4 and a layer of diffusion liquid storage layer 5 connected to the lower surface of the absorbent layer 4 .

[0048] The absorbent layer 4 includes a non-woven fabric layer and SAP3 disposed in the voids of the non-woven fabric layer 41 . The absorption layer 4 is provided with X first guide grooves 42, which divide the absorption layer 4 into a plurality of absorption regions. The first guide groove 42 is a sinusoidal curve arranged in parallel.

[0049]The diffusion storage layer 5 includes a non-woven fabric layer 51 and SAP3 disposed in the gaps of the non-woven fabric layer 51 . Y second guide grooves 52 are arranged on the diffusion liquid storage layer 5 . The second guide groove 52 is rhomboid, and a plurality of rhombic second guide grooves 52 are connected in series to form the guide diffusion channel 6 . Said X and Y are positive integers, Y≥X.

[0050] On the diffusion storage l...

Embodiment 2

[0053] Such as Figure 6~7 As shown, Example 1 is repeated, with the difference that: the diffusion liquid storage layer 5 is stacked with two layers in sequence, and the number of second guide grooves 52 in the lower layer is greater than that in the upper layer. The flow guide diffusion channels 6 formed by the second flow guide grooves 52 on the upper diffusion liquid storage layer 5 are alternately arranged with the flow guide diffusion channels 6 formed by the second flow guide grooves 52 on the lower diffusion liquid storage layer 5, It has an included angle θ, and the value of θ is [0°, 90°].

[0054] The second guide groove 52 is rectangular, and a plurality of rectangular second guide grooves 52 are connected in series to form the guide diffusion channel 6 .

Embodiment 3

[0056] Such as Figure 8-9 As shown, Example 2 is repeated, the difference is: the diffusion liquid storage layer 5 is stacked with three layers in sequence. The structure and arrangement form of the first and second diffusion liquid storage layers 5 are the same as those of the diffusion liquid storage layer 5 in the second embodiment. The second guide groove 52 on the diffusion liquid storage layer 5 of the third layer is a long strip (such as Figure 9 shown), and there is an included angle β between the second guide groove 52 and the longitudinal axis of the diffusion storage layer 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com