A Calculation Method for Temperature Field of Multi-Turn Closely Wound Coil Combining Thermal Resistance Network Method and Finite Difference Method

A finite-difference method and densely wound coil technology, which is applied in the calculation field of the rapid solution of the temperature field of two-dimensional axisymmetric coils, can solve problems such as unsuitable for more accurate calculation, inter-turn short circuit, and affecting the insulation effect and life of the enameled wire insulation varnish layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

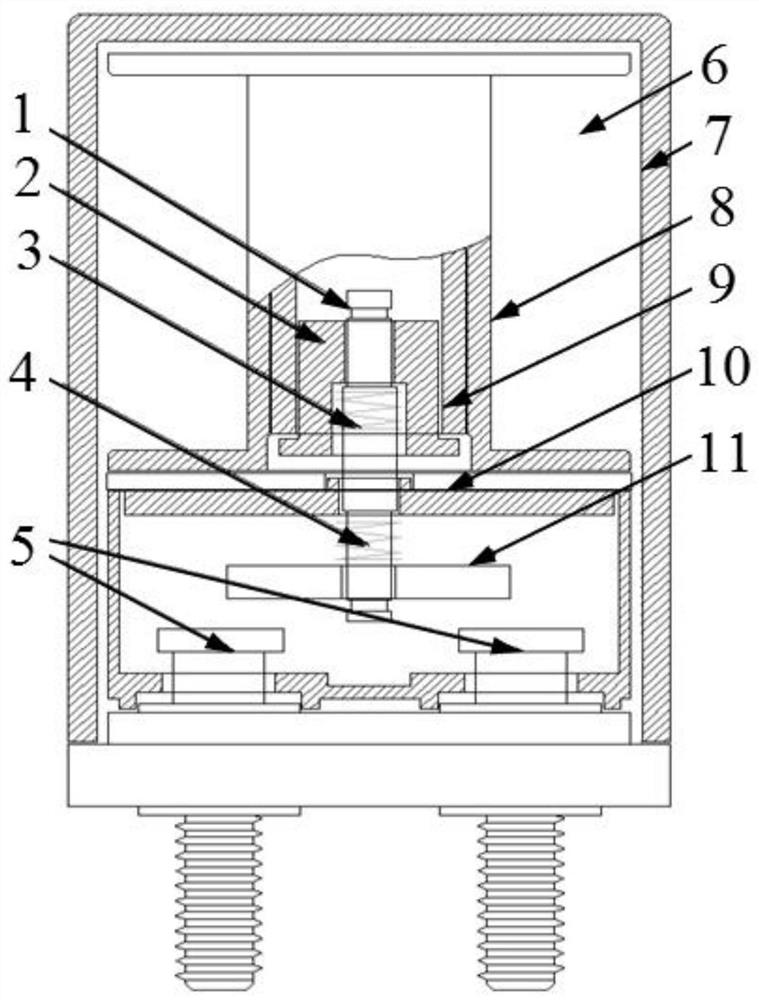

[0049] Calculate for the inner coil of a certain type of contactor.

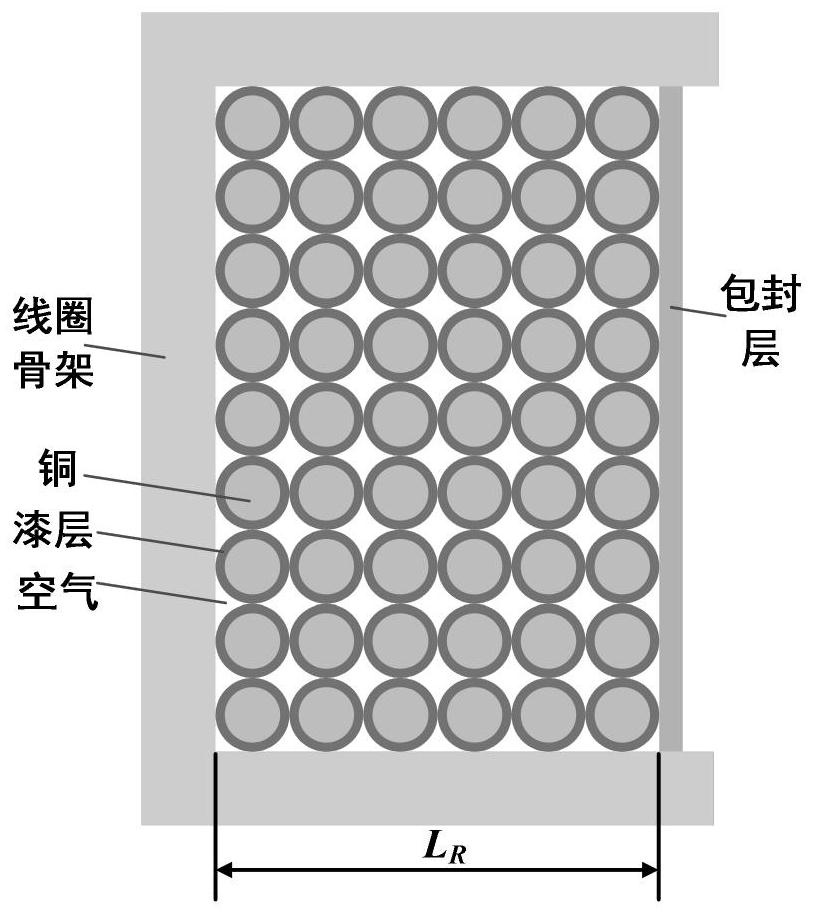

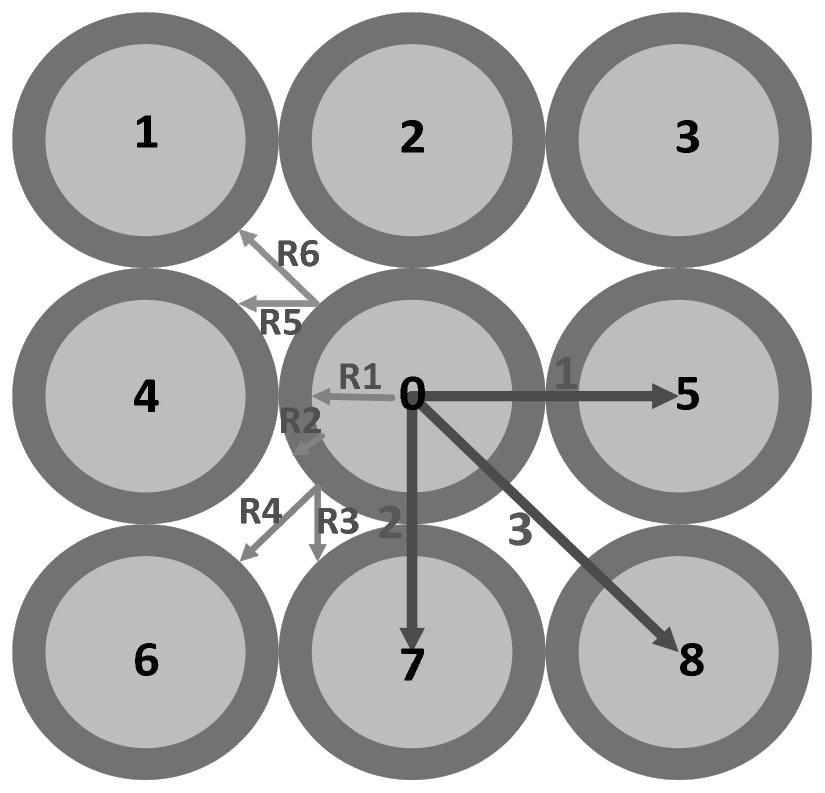

[0050] The outer diameter of the coil skeleton is 46mm, the diameter of the copper wire is 0.35mm, the outer diameter of the paint layer is 0.4mm, and there are 2100 turns in total. The coil resistance is about 37.5Ω at room temperature, and the voltage is 28V at both ends, and the initial power is P 0 About 20.91W. The thermal conductivity of the material is assumed to be a constant that does not change with temperature, but as the temperature increases, the resistivity of the copper wire will change, which in turn will affect the power at steady state. Copper wire resistivity ρ changes with temperature rise τ reference formula: ρ=ρ 0 (1+0.00393τ), where: ρ 0 is the resistivity of the material when the temperature rise is zero. Power in steady state: P=P 0 / (1+0.00393τ). The arrangement of the copper wires is judged to be aligned, and the thermal resistance network refers to image 3 , the average di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com