Basket type cantilever scaffold

A cantilevered scaffolding and basket-type technology, which is applied to scaffolding accessories, scaffolding supported by housing structures, and housing structural support, etc., can solve problems such as waste of formwork openings, leakage of reserved holes in walls, and difficulty in removing profiled steel. To achieve the effect of improving stability and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

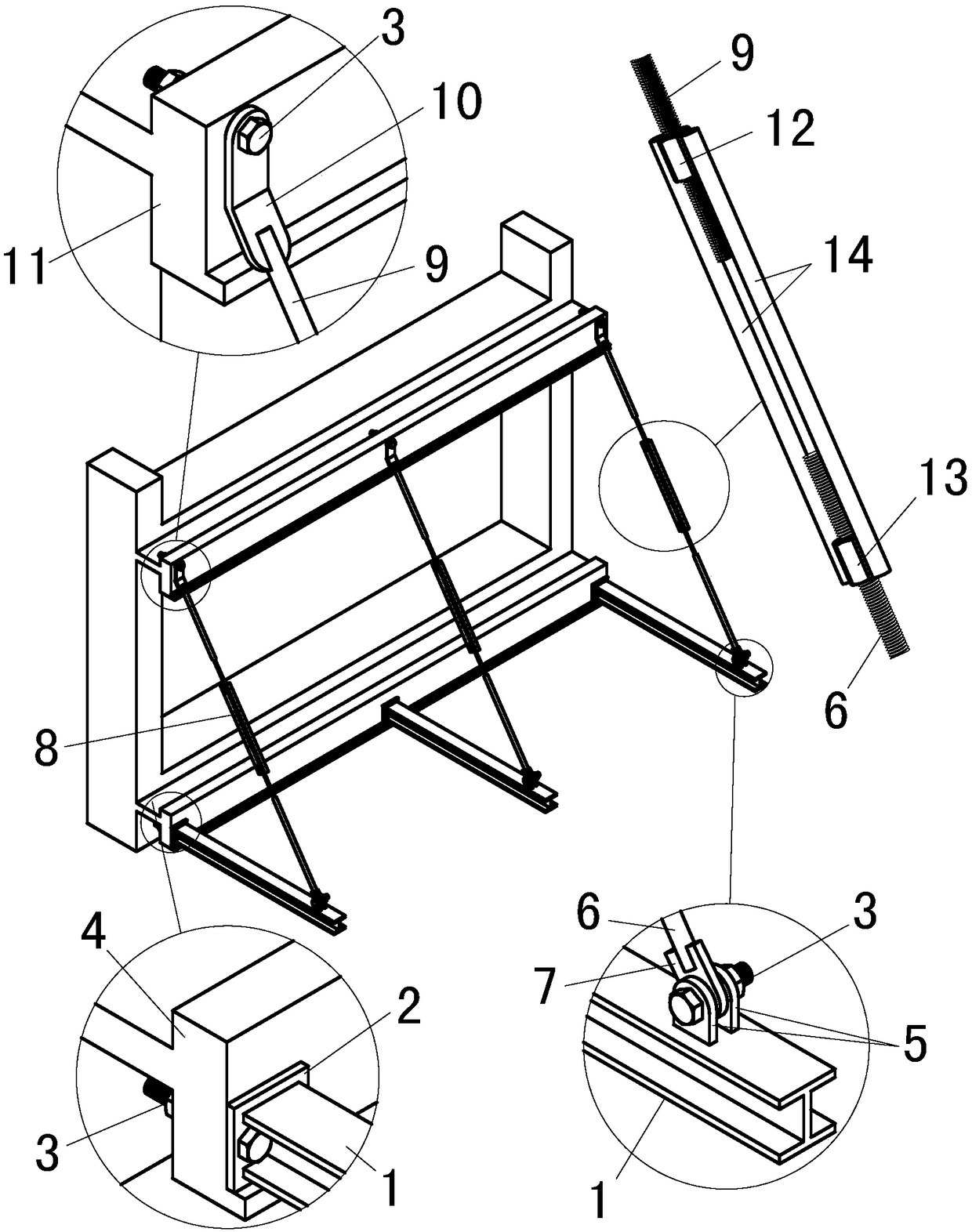

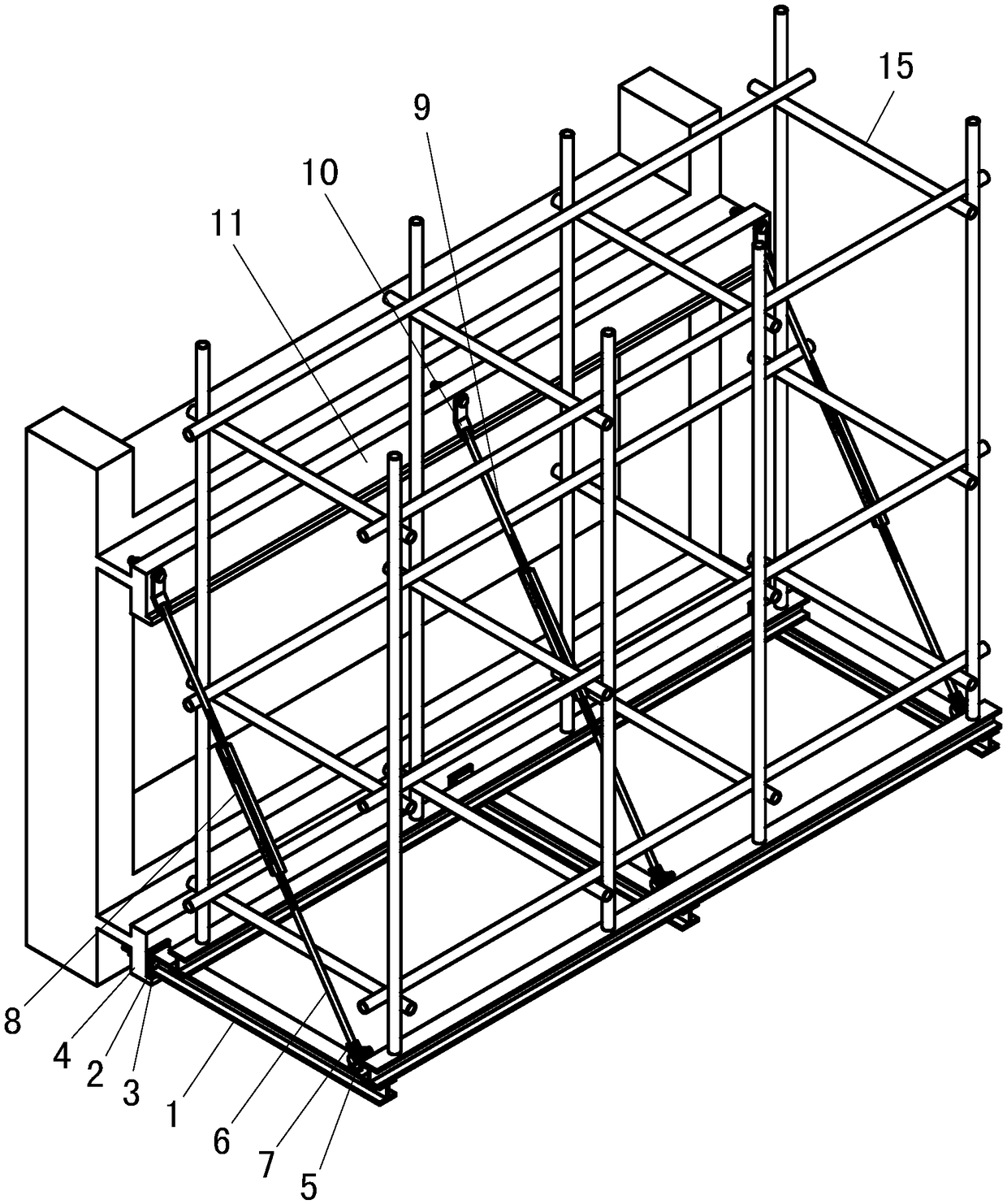

[0017] The construction method of this example, such as figure 1 shown. During specific implementation, follow the steps below for construction:

[0018] (1) Positioning and setting out

[0019] According to the plane shape and size of the building structure, the positioning of the cantilevered steel is determined. After the structural steel bars are bound and before the mold is sealed, the pre-buried casing is reserved for the wall hole, and then the concrete is poured and maintained, and the formwork is removed to clean the wall hole.

[0020] (2) Fabrication of horizontal force-bearing components

[0021] The horizontal force component is composed of section steel 1, rear connection plate 2 and front connection plate 5; all the above-mentioned parts are steel components, section steel 1 is made of 18# I-beam, rear connection plate 2 is made of 200×180×12 steel plate, front The connecting plate 5 is made of 120×120×12 steel plates. Among them: the rear connection plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com