Vertical connection structure of prefabricated concrete shear wall and construction method thereof

A prefabricated concrete and shear wall technology, applied in building structures, walls, building components, etc., can solve the problems of difficult alignment of steel bars, difficult quality assurance, and difficult grouting, etc., to ensure vertical continuity and construction difficulty. The effect of low and high construction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, structure of the present invention, construction process are further described as follows.

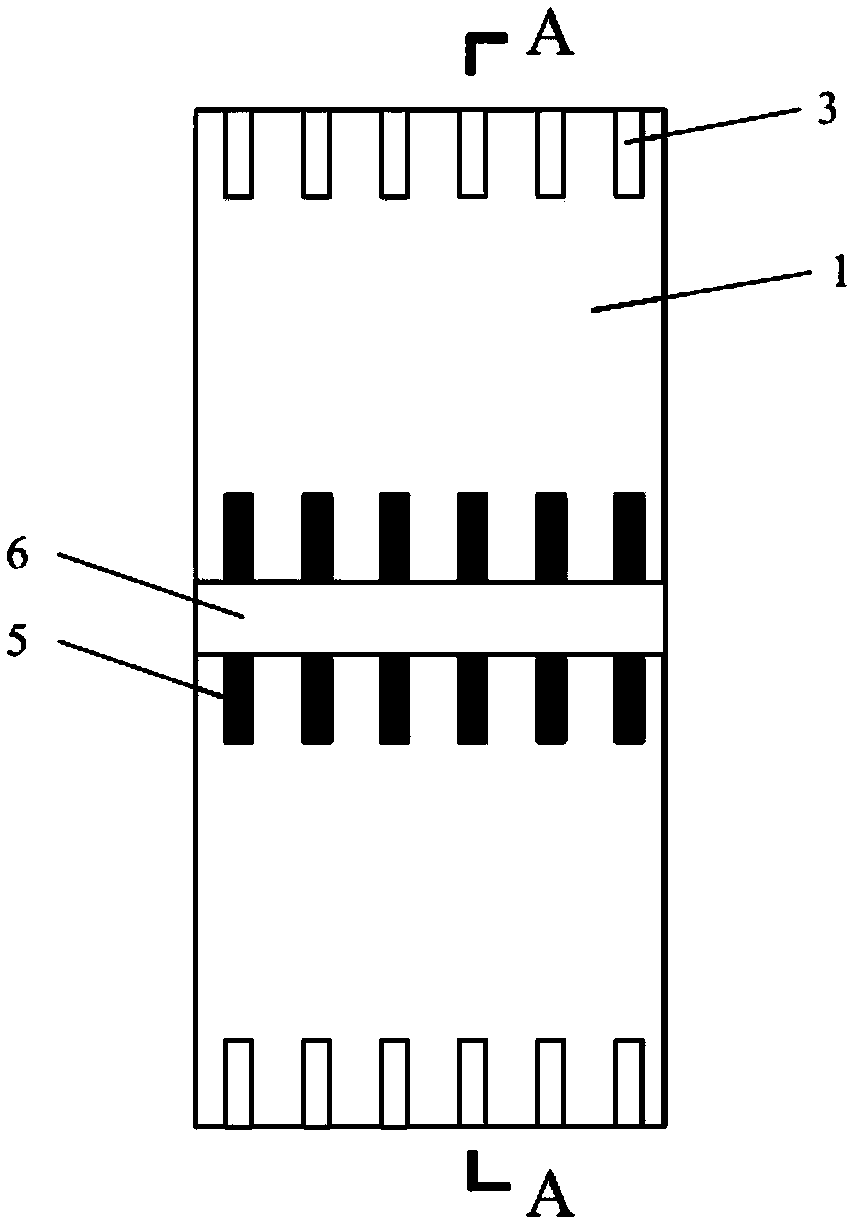

[0026] Such as figure 1 As shown, a kind of prefabricated concrete shear wall vertically connected structure of the present invention comprises prefabricated concrete shear wall 1, vertical stress reinforcement 2 in the wall, additional reinforcement 4, hole-filling cement-based cementitious material 5 and concrete Post-pouring belt 6; a row of strip slots 3 are reserved at the top and bottom of precast concrete shear wall 1, and the strip slots 3 are evenly distributed between the vertical stressed steel bars 2 in the shear wall, and the strip slots The depth of 3 is the thickness of the precast concrete shear wall 1 minus the thickness of the reinforcement protective layer; when the precast concrete shear wall 1 is spliced vertically, the strip-shaped slot holes 3 of the upper and lower walls are aligned and connected at the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com