Improved production process for producing corrugated core paper by using waste paper

A corrugated core paper and production process technology, applied in papermaking, paper recycling, textiles and papermaking, etc., can solve the problems of reduced physical properties, increased water consumption, fiber damage, etc., to reduce input and addition, and reduce papermaking water consumption. , the effect of reducing damage to fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

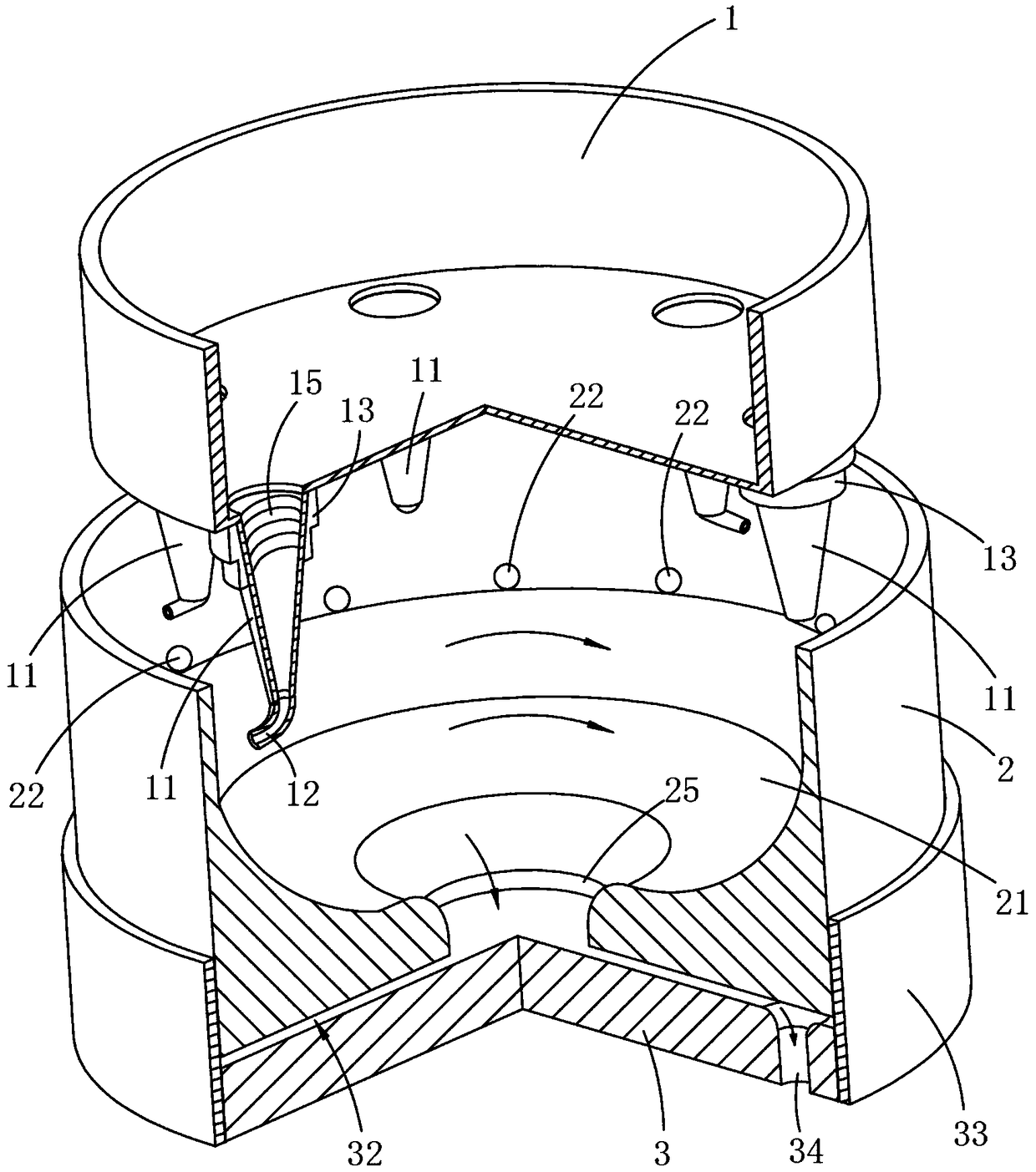

Image

Examples

Embodiment Construction

[0043] The following are only preferred embodiments of the present invention and do not limit the protection scope of the present invention.

[0044] An improved production process of using waste paper to produce corrugated core paper includes the following steps:

[0045] In the paper cutting step, the recovered waste paper is cut into thin strips by a slitting machine to obtain strip waste paper.

[0046] In the pulping step, the strip-shaped waste paper is put into the pulping bucket, the recycled water of the papermaking enterprise is injected into the pulping bucket, and the strip-shaped waste paper is broken into a slurry, and the slurry in the pulping bucket is divided to obtain waste Paper pulp.

[0047] In the sludge sewage treatment step, heavy slag is removed from the bottom of the pulping bucket, the sewage and sludge in the heavy slag are separated through the mud-water separation equipment, and the sludge is transported to the sludge drying treatment equipment for drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com