A kind of genetically engineered bacteria for l-theanine production and fermentation method thereof

A technology of genetically engineered bacteria and theanine, applied in the field of bioengineering, to achieve the effects of simple ingredients, easy separation and purification, and short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

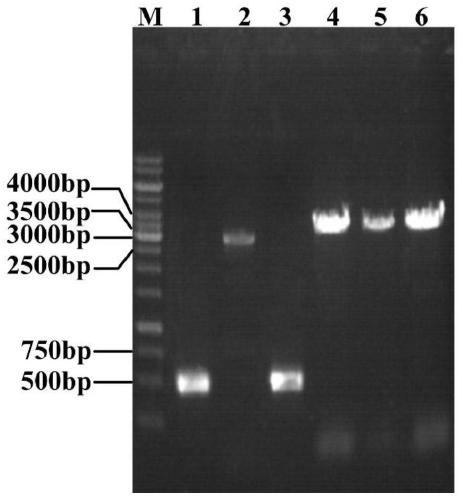

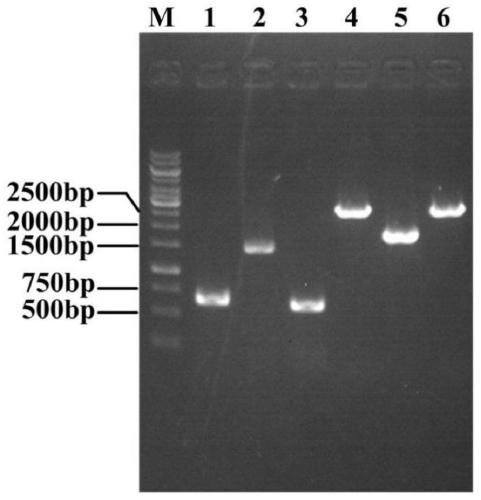

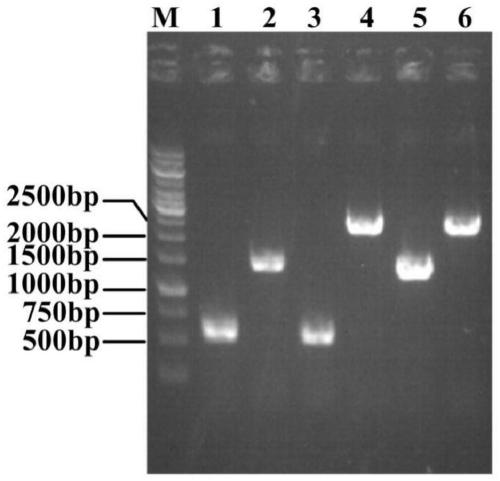

[0036] Example 1: Construction method of genetically engineered bacteria with high L-theanine production

[0037] 1. Integrate the RNA polymerase gene derived from T7 phage into the lacI-lacZ site of the genome of E.coli W3110

[0038] Using the E.coli W3110 (ATCC27325) genome as a template, design upstream homology arm primers UP-lacI-lacZ-S (see Sequence Table 5 for the nucleotide sequence) and UP-lacI-lacZ according to the upper and lower sequences of its lacI-lacZ gene -A (see Sequence Table 6 for the nucleotide sequence) and downstream homology arm primers DN-lacI-lacZ-S (see Sequence Table 7 for the nucleotide sequence), DN-lacI-lacZ-A (see Sequence Table 7 for the nucleotide sequence) list 8), and PCR amplification of its upstream and downstream homology arm fragments; obtain the T7RNAP gene sequence by gene synthesis, which contains xylose promoter P xylF , design primers T7RNAP-S (see Sequence Table 9 for nucleotide sequence) and T7RNAP-A (see Sequence Table 10 for n...

Embodiment 2

[0051] Example 2: Production of L-theanine by fermentation in a 5L fermenter

[0052] 1. Medium

[0053] The composition of the slant medium is: glucose 1g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium chloride 2.5g / L, agar 25g / L, pH 7.0;

[0054] The composition of the seed medium is: glucose 25g / L, yeast extract 10g / L, peptone 15g / L, sodium chloride 15g / L, pH 7.2.

[0055] The composition of the fermentation medium is: glucose 30g / L, yeast extract 10g / L, peptone 15g / L, potassium dihydrogen phosphate 5g / L, magnesium sulfate 2g / L, pH 7.2.

[0056] Slope activation culture: Scrape a ring of strains from the bacteria preservation tube of the -80°C refrigerator, spread evenly on the activation slope, incubate at 37°C for 12 hours, transfer to an eggplant-shaped bottle and continue to cultivate for 12 hours;

[0057] 2. Fermentation method

[0058] Seed culture: Take an appropriate amount of sterile water in an eggplant-shaped bottle, insert the bacterial susp...

Embodiment 3

[0063] Effects of different feeding methods of ethylamine on the fermentation of L-theanine in a 5L fermenter

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com