Preparation method of olive vinegar

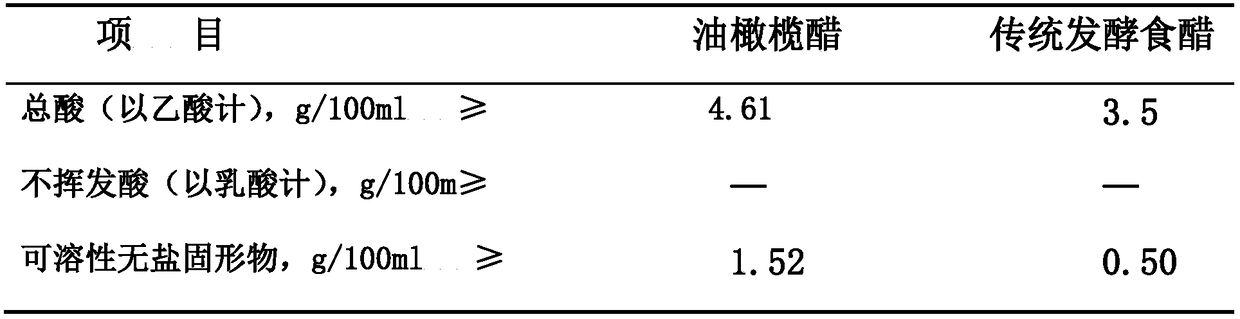

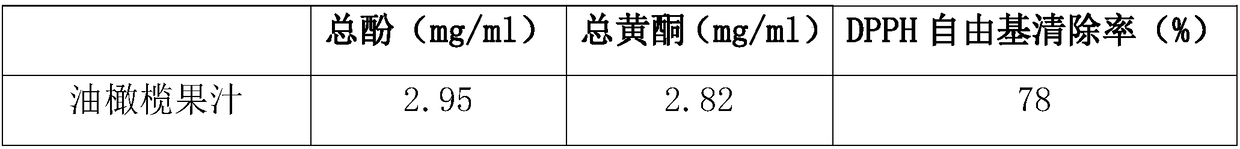

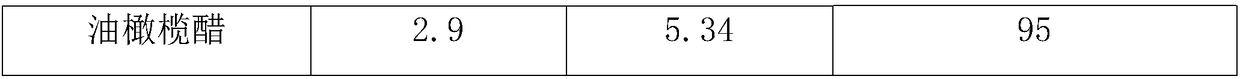

A technology of olives and olive raw fruits, applied in the field of olive vinegar preparation, which can solve the problems of low utilization rate of olive products, poor sensory quality of vinegar, thin taste, etc., and achieve the effects of inhibiting bacterial reproduction, improving flavor and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of the olive vinegar of the present embodiment comprises the following steps: a. Preparation of rice koji: a1. Soak 5 parts of washed rice in water for 40 minutes, drain for 0.5 hours, cook for 40 minutes, and spread to cool to a temperature of 25°C , making steamed rice with a water content of 30-35%;

[0018] a2. Insert the spore suspension into the steamed rice and add the powder of Chinese herbal medicines, mix well and place in a constant temperature and humidity incubator with a relative humidity of 95% and a temperature of 38°C for accumulation and cultivation for 22 hours. The second time, culture at a temperature of 32°C for 22 hours, turn over and spread out, control the temperature to 40°C, remove humidity at the same time, and ventilate and dry for 11-13h. Sedum: licorice = 5:3:2:1:1:1 mixture;

[0019] b. Crush 10 parts of olive leaves and mix with 60 parts of olive juice, add 5 parts of glutinous rice and mix evenly, then put it in ...

Embodiment 2

[0026] The preparation method of the olive vinegar of the present embodiment comprises the following steps: a. Preparation of rice koji: a1. Soak 15 parts of washed rice in water for 60 minutes, drain for 0.5 hours, cook for 60 minutes, and then cool to a temperature of 35°C , making steamed rice with a water content of 30-35%;

[0027] a2. Insert the spore suspension into the steamed rice and add Chinese herbal medicine powder, mix well and place in a constant temperature and humidity incubator with a relative humidity of 95% and a temperature of 38°C for stacking and culturing for 25 hours, spread out and cool down and then stack for 1 Once again, cultivated at a temperature of 32°C for 25 hours, turned over and spread out, controlled the temperature at 40°C, removed humidity simultaneously, and ventilated and dried for 13 hours. : Licorice = 5:3:2:1:1:1 mixture;

[0028] b. Mix 20 parts of olive leaves with 70 parts of olive juice, add 10 parts of glutinous rice and mix ev...

Embodiment 3

[0035] The preparation method of olive vinegar of the present invention comprises the following steps: a. Preparation of rice koji: a1. Soak 5 parts of washed rice in water for 60 minutes, drain for 0.5 hours, cook for 40 minutes, and then cool to a temperature of 35°C , making steamed rice with a water content of 30-35%;

[0036] a2. Insert the spore suspension into the steamed rice and add the powder of Chinese herbal medicines, mix well and place in a constant temperature and humidity incubator with a relative humidity of 95% and a temperature of 38°C for accumulation and cultivation for 22 hours. Next, cultivate 25 hours at a temperature of 32°C, turn over and spread out, control the temperature to 40°C, remove humidity simultaneously, and ventilate and dry for 11 hours. : Licorice = 5:3:2:1:1:1 mixture;

[0037] b. Crush 20 parts of olive leaves and mix with 60 parts of olive juice, add 10 parts of glutinous rice and mix evenly, then put it into the wood trembler and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com