Production process of expanding single line capacity of acetylene black by mixing gas

A technology of acetylene carbon black and production process, applied in the direction of fibrous fillers, etc., can solve the problems of low output, high operation cost of a single production line, high labor cost, and achieve the effect of simple production process, good social benefits, and improved economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

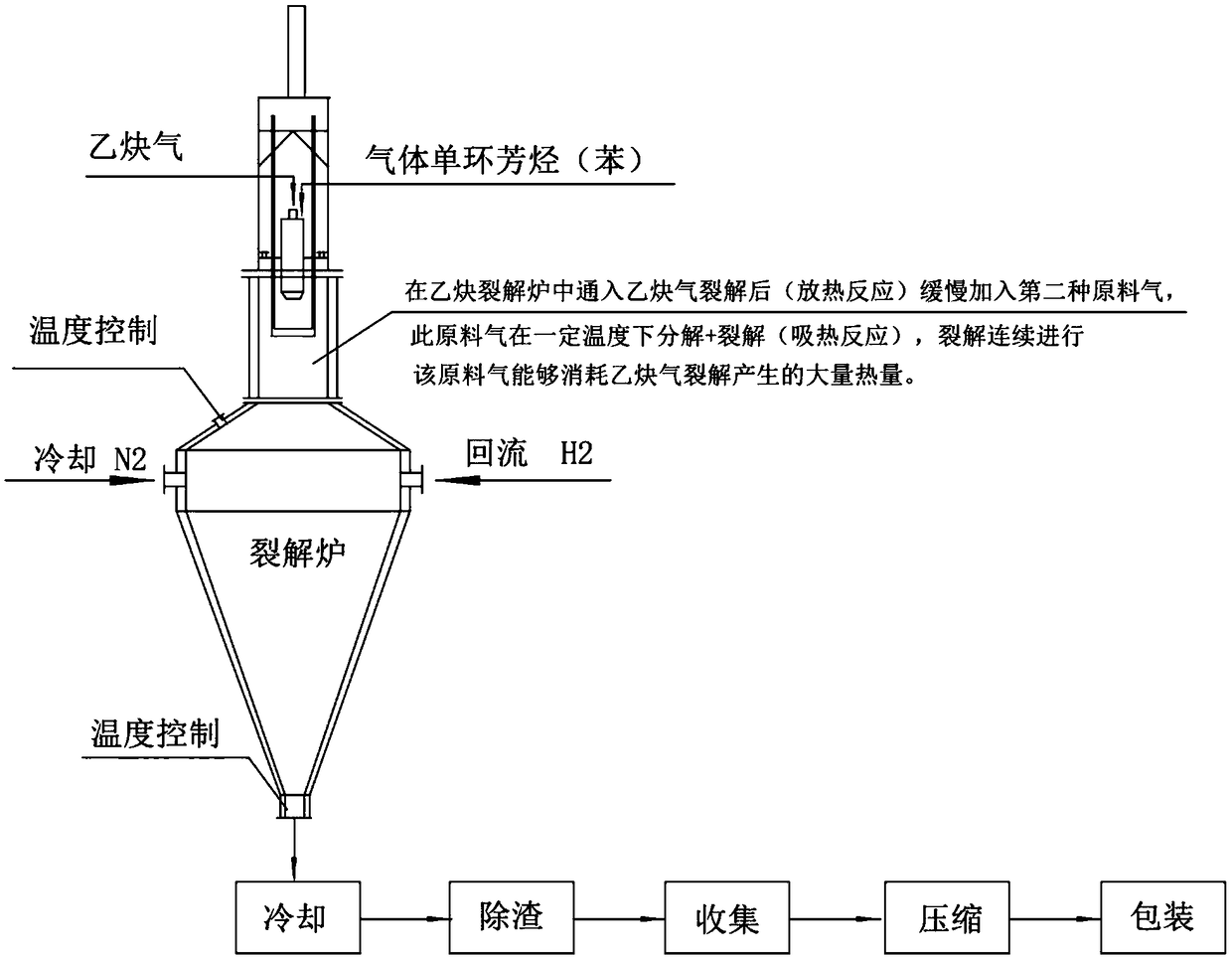

[0023] Such as figure 1 Shown, a kind of gas mixing expands the production technique of acetylene carbon black single-line production capacity, comprises the following steps:

[0024] a. Renovate the acetylene cracking furnace and add a feed gas inlet;

[0025] b. Feed the first raw material gas, acetylene gas, into the acetylene cracking furnace through the original air inlet. After the cracking of the acetylene gas, feed the second raw material gas into the acetylene cracking furnace through the newly added air inlet. The second The raw material gas can absorb the heat generated by acetylene cracking for its own decomposition and cracking;

[0026] c. When the acetylene gas is constant, the outlet temperature of the cracking furnace is controlled according to the furnace pressure, and the amount of cooling medium is adjusted, so as to achieve the purpose of cutting off the flame, terminating the carbon black reaction, diluting the carbon black concentration, and preventing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com