Polyester with low oligomer content and preparation method of polyester

An oligomer and content technology, applied in the field of polymer materials, can solve the problems of reducing the oligomer content in polyester, dyeing uniformity interference, etc., to reduce the oligomer content, low oligomer content, quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

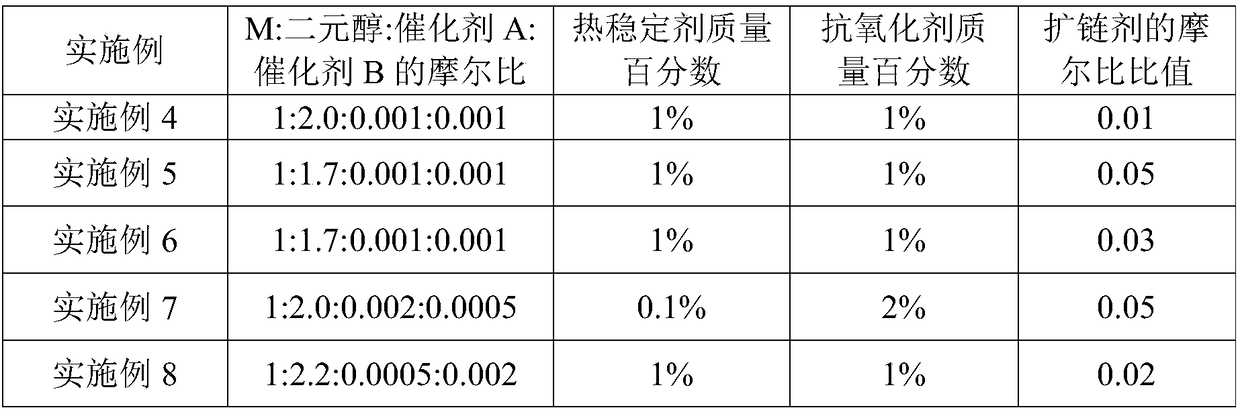

Examples

Embodiment 1

[0048] A preparation method of polyester with low oligomer content, the steps are as follows:

[0049] (1) Add dimethyl terephthalate (291g), 1,4-butanediol (189g) and tetrabutyl titanate (0.7g) into a 2L polymerization reactor, and use vacuum / nitrogen circulation for 3 times as much as possible It is possible to exclude the residual air in the reaction kettle, and apply a slow nitrogen flow to the reaction system, then heat to 125°C to distill the by-product methanol, and gradually raise the temperature to 190°C to maintain the esterification reaction until the amount of methanol evaporated reaches 95% of the theoretical value;

[0050] (2) Vacuumize the reaction system to implement the first-stage polycondensation reaction, the vacuum degree is 1KPa, the set reaction temperature is 220°C, and the reaction time is 0.5h;

[0051] (3) Apply a high vacuum to the reaction system (vacuum degree is 90Pa), and increase the reaction temperature to 260°C to carry out the second stage ...

Embodiment 2

[0062] A preparation method of polyester with low oligomer content, the preparation steps are basically the same as in Example 1, the difference is that in step (5), chain extender hexamethylene diisocyanate (15g) is added to carry out chain extension reaction .

[0063] The intrinsic viscosity and oligomer content of the finally obtained polyester are shown in Table 1.

Embodiment 3

[0065] A preparation method of polyester with low oligomer content, the steps are as follows:

[0066] (1) Add dimethyl terephthalate (310.7g), 1,4-butanediol (259.5g), tetrabutyl titanate (3.3g) and antioxidant 1010 (6.0g) into a 2L polymerization reactor ), use vacuum / nitrogen circulation 3 times to remove residual air in the reactor as much as possible, and apply a slow nitrogen flow to the reaction system, then heat to 125°C to distill out the by-product methanol, and gradually raise the temperature to 190°C to maintain the esterification reaction until the methanol Evaporated amount reaches 95% of theoretical value;

[0067] (2) Vacuumize the reaction system to implement the first-stage polycondensation reaction, the vacuum degree is 1KPa, the set reaction temperature is 220°C, and the reaction time is 0.5h;

[0068] (3) Apply a high vacuum to the reaction system (vacuum degree is 90Pa), and increase the reaction temperature to 260°C to carry out the second stage polycon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com