A kind of medical rubber and its preparation method and application

A technology of rubber and rubber stoppers, applied in the field of polymers, can solve the problems of low content of oligomers, difficulties, etc., and achieve the effect of solving poor compatibility and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] Exemplarily, the preparation method includes the steps of: at least one isoolefin monomer and at least one conjugated diene monomer, and a slurry polymerization reaction occurs in the polar solvent under the action of a Lewis acid and an initiator ; Or, the polymerization reaction product is reacted with chlorine or liquid bromine.

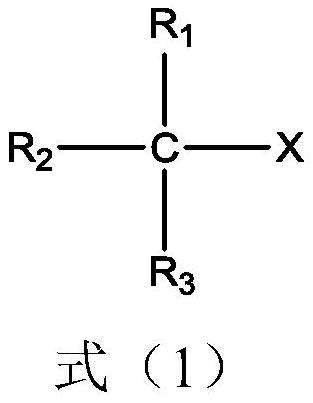

[0085] R in the initiator R-X is a polyisobutenyl group, and R has the structure shown in formula (2):

[0086]

[0087] Wherein, k≥4, such as k≥5, another example k≥10, another example k≥20, exemplarily, k=4, 5, 6, 7, 8, 9, 10, 13, 17, 19 or 22 ; X is Cl.

[0088] Exemplarily, the medical rubber is butyl rubber or chlorinated butyl rubber, and the butyl rubber is prepared by a method comprising the following steps: isobutylene monomer and isoprene monomer, in Lewis acid and initiator react in a solvent under the action;

[0089] The chlorinated butyl rubber is prepared by a method comprising the following steps: isobutylene monomer a...

Embodiment 1

[0100] Butyl rubber, which is a medical rubber, is prepared from isobutylene monomer and isoprene monomer by cationic polymerization. Its number average molecular weight is between 50,000 and 200,000, and its molecular weight distribution index is between 1.5 and 4.0.

[0101] The butyl rubber is used to prepare medical rubber stoppers, and the method for improving the compatibility between medicines and butyl rubber in medical rubber stoppers, wherein the butyl rubber is prepared by the following steps:

[0102] In an anhydrous and oxygen-free glove box, add monochloromethane to a glass reactor with mechanical stirring, cool it to -95 ° C, add isobutylene monomer and isoprene monomer, the concentration of isobutylene is 10wt%, isoprene The concentration is 0.28 wt%. After stirring, the mixture of Lewis acid and initiator is added, and the catalytic reaction proceeds to obtain butyl rubber. The additions and proportions of Lewis acid and initiator are shown in Table 1.

[0...

Embodiment 2-6

[0108] In an anhydrous and oxygen-free glove box, the mixed solvent of isopentane and ethyl chloride (weight ratio of isopentane / ethyl chloride = 3:1) was added to a glass reactor with mechanical stirring, cooled to -80 °C, and isobutylene was added. Monomer and isoprene monomer, the concentration of isobutene was 10 wt% and the concentration of isoprene was 0.28 wt%. After stirring, the mixture of Lewis acid and initiator is added, and the catalytic reaction proceeds to obtain butyl rubber. The additions and proportions of Lewis acid and initiator are shown in Table 2. Initiators R-X were prepared from isobutylene polymer and HCl according to methods known in the art.

[0109] Table 2.

[0110] Example Initiator * (ppm)

[0111] Note*: RCl refers to the structural formula such as formula (2), Mn and PDI refer to the molecular weight of R, and RCl molecular weight distribution coefficient (Mw / Mn).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com