Preparation method of aromatic vinyl-unsaturated nitrile copolymer and prepared aromatic vinyl-unsaturated nitrile copolymer

An aromatic vinyl, unsaturated technology, applied in the preparation of aromatic vinyl-unsaturated nitrile copolymers and the field of prepared aromatic vinyl-unsaturated nitrile copolymers, can solve the problem of low oligomer content , Lack of impact resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

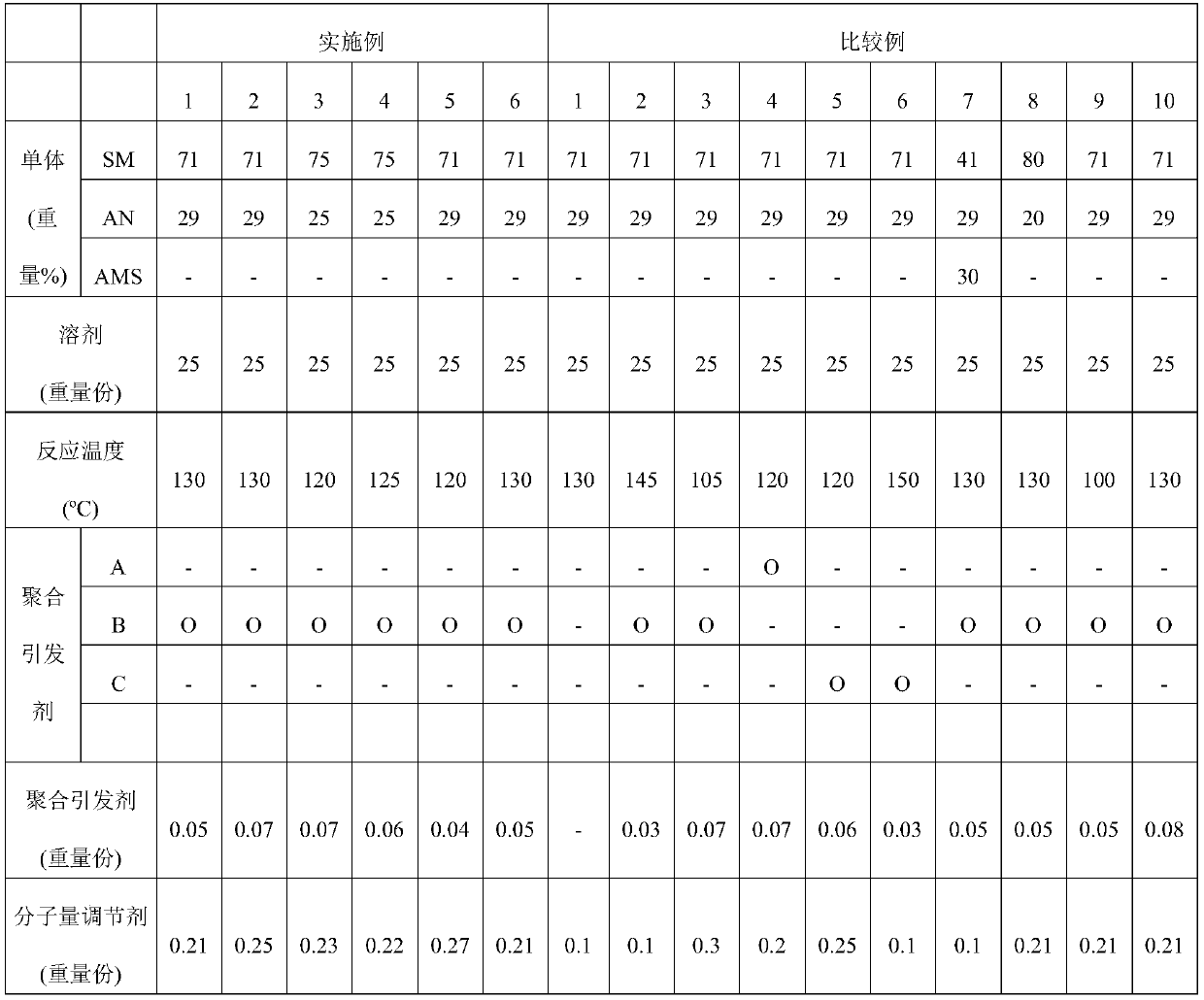

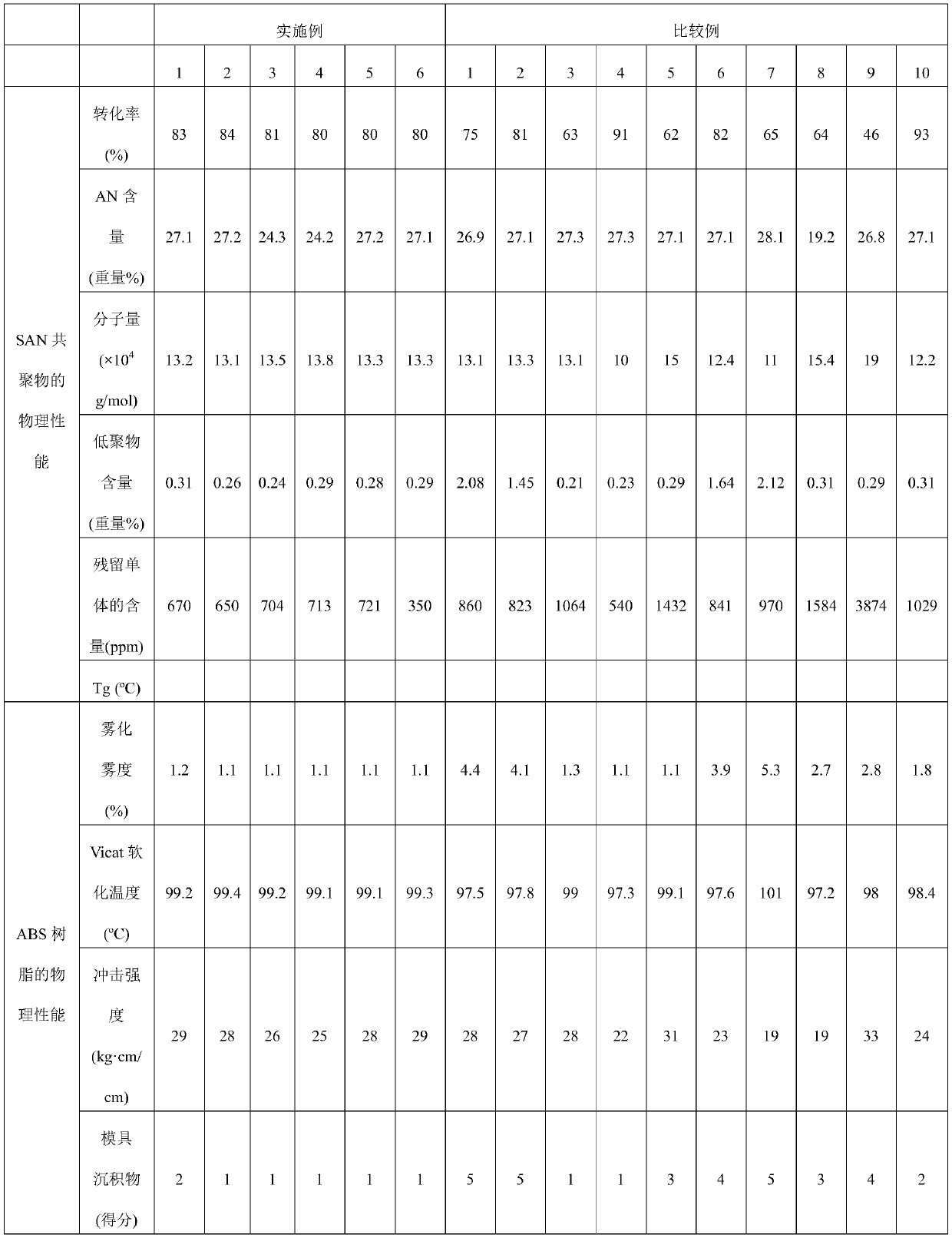

[0023] Specifically, the preparation method of the aromatic vinyl-unsaturated nitrile copolymer according to one embodiment of the present invention includes: adding aromatic vinyl monomers with a weight ratio of 65:35 to 78:22 to the reaction solvent monomers and unsaturated nitrile monomers to prepare a mixed solution, by adding to the mixed solution a polymerization initiator comprising an organic peroxide having a half-life temperature of 100° C. to 120° C. so that based on 100 parts by weight of all monomers , the content of the polymerization initiator is in the range of 0.01 parts by weight to 0.08 parts by weight, and then the polymerization is carried out at 115°C to 135°C so that the monomer conversion rate is more than 80%, to prepare the step of the polymerization product (step 1); and The polymerized product is subjected to a devolatilization process to prepare an oligomer content of less than 0.5 parts by weight (based on 100 parts by weight of the copolymer), a r...

Embodiment 1

[0062]A mixed solution was prepared by dissolving 71 parts by weight of styrene and 29 parts by weight of acrylonitrile in toluene (TLN). Here, toluene was used in an amount of 25 parts by weight based on 100 parts by weight of the total weight of all monomers. Furthermore, 0.05 parts by weight of 1,1-bis(tert-butylperoxy)cyclohexane as a polymerization initiator and 0.21 parts by weight of tert-dodecylmercaptan (TDDM) as a molecular weight regulator, and copolymerized at a reaction temperature of 130°C. The obtained polymer product was subjected to a devolatilization process at a temperature of 230° C. and a pressure of 20 Torr to prepare a styrene-acrylonitrile (SAN) copolymer.

[0063] Mix 73 parts by weight of the SAN copolymer thus prepared with 27 parts by weight of ABS DP (polybutadiene grafted with SAN), 0.25 parts by weight of antioxidant and 0.7 parts by weight of lubricant, and prepare heat-resistant permanent resin composition. The heat-resistant resin compositi...

Embodiment 2 to 5

[0065] Each SAN copolymer and heat-resistant resin composition were prepared in the same manner as in Example 1 except that the materials were used in the amounts listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com