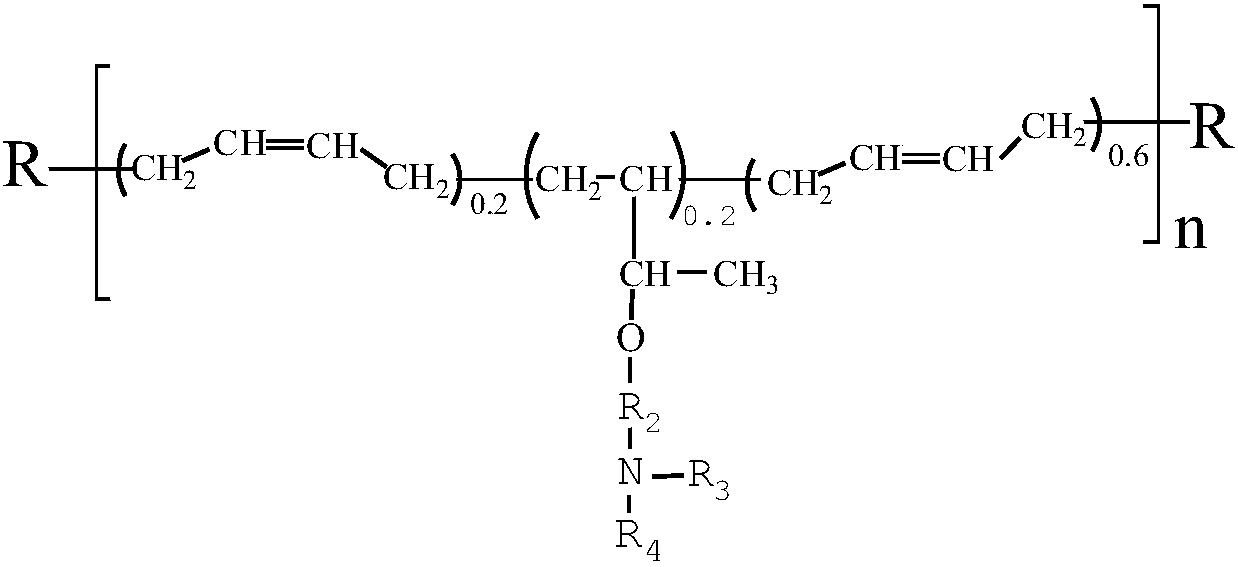

Synthesis method for polymer acrylate resin with photosensitive self-catalytic activity

An acrylate, autocatalytic technology, applied in non-polymer adhesive additives, non-polymer organic compound adhesives, adhesive additives, etc., can solve the problem of poor toughness of cured products, poor flexibility of adhesive layer, Problems such as poor surface dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 30g of tert-butyldiphenylchlorosilane and 0.5g of diethyltetramethylimidazole under nitrogen protection, and react at 30°C for 4 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0026] Add the above reactant to 22 g of HBr with a concentration of 40%, and react at 70°C for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0027] Add 55 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0028] Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.26g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; after the above rotary evaporation The obtained product was vacuumized at 115°C for ...

Embodiment 2

[0030] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 35g of tert-butyldiphenylchlorosilane and 1.5g of diethyltetramethylimidazole under nitrogen protection, and react at 40°C for 2 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0031] Add 20 g of the above reactant to 40% HBr, and react at 70°C for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0032] Add 70 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0033] Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.50g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; after the above rotary evaporation The obtained product was vacuumized at 110°C for 3 hours to remove moistu...

Embodiment 3

[0035] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 30g of tert-butyldiphenylchlorosilane and 1.0g of diethyltetramethylimidazole under nitrogen protection, and react at 40°C for 4 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0036] Add 26 g of the above reactant to 40% HBr, and react at 70°C for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0037] Add 48 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0038] Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.38g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; after the above rotary evaporation The obtained product was vacuumized at 113°C for 2.5 hours to remove mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com