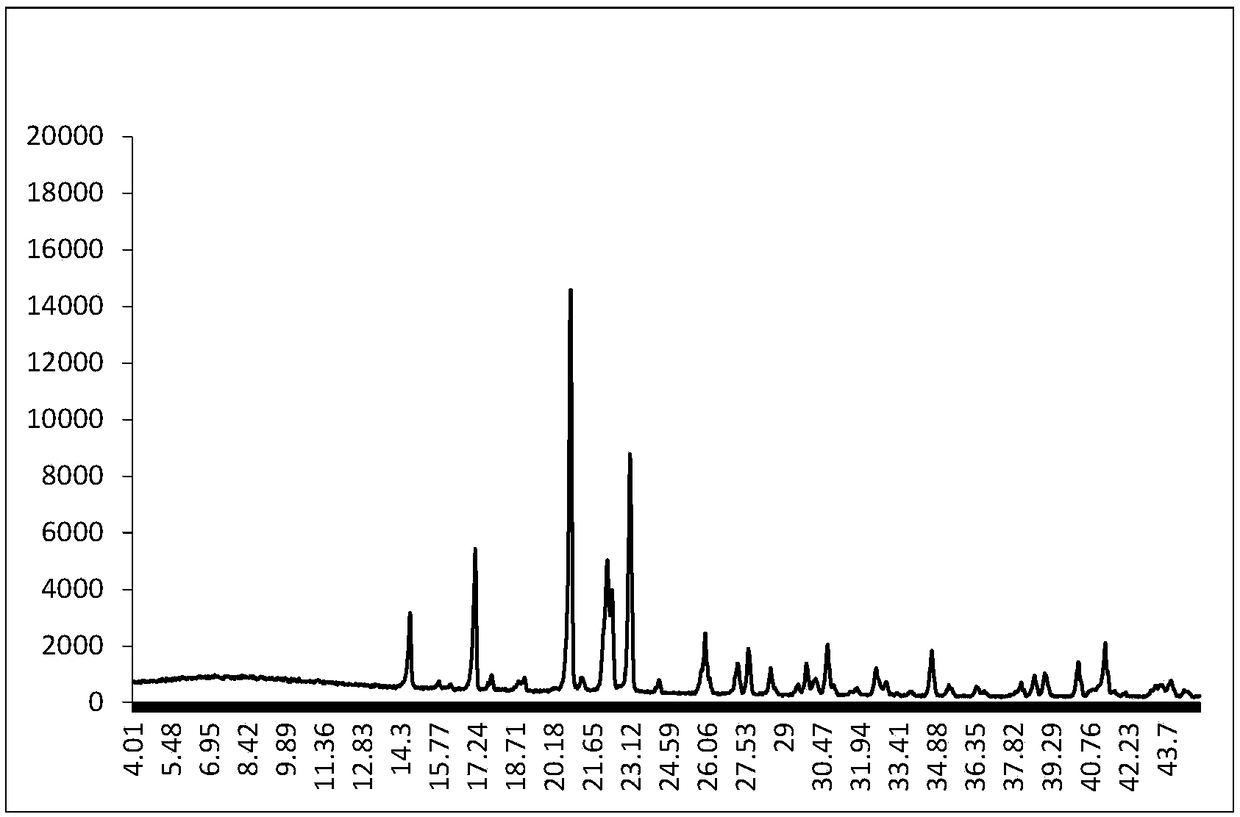

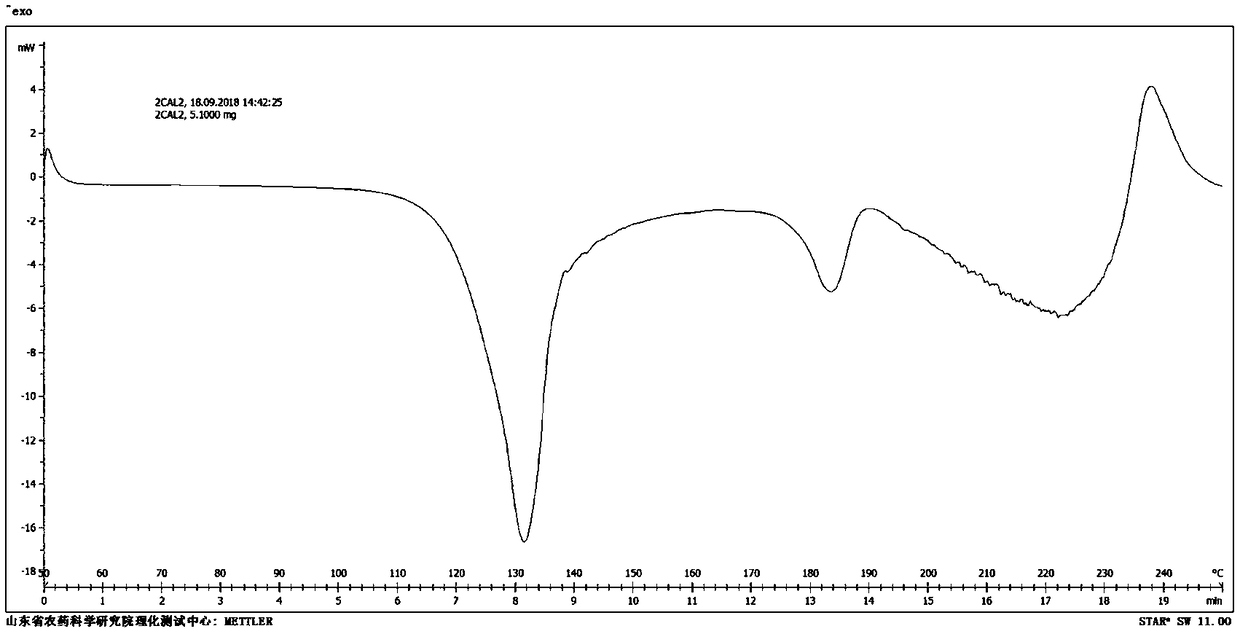

Refined glufosinate acid aquo-complex crystals and preparation method thereof

A technology of hydrate and ammonium glufosin, which is applied in the field of pesticides, can solve the problems of differences in bioavailability, achieve good fluidity, improve the quality of drug production, and make the preparation method simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, add refined glufosinate-ammonium hydrochloride (1mol) into 200ml of water and 200ml of methanol, heat up to 60°C to dissolve, cool down to 30°C, and feed 18.7g of ammonia gas; then, stir at room temperature for 20 minutes, cool down Stir at -10°C for 3 hours to crystallize, filter the precipitated crystals, wash with methanol and dry to obtain 179.1 g of refined glufosinate-ammonium monohydrate crystals with a yield of 90% and a purity of 98%.

Embodiment 2

[0040] First, add refined glufosinate-ammonium hydrochloride (1mol) into 100ml of water and 300ml of methanol, heat up to 60°C to dissolve, cool down to 30°C, and feed 18.7g of ammonia gas; then, stir at room temperature for 20 minutes, cool down Stir at -5°C for 3 hours to crystallize, filter the precipitated crystals, wash with methanol and dry to obtain 185.1 g of refined glufosinate-ammonium monohydrate crystals with a yield of 93% and a purity of 97.9%.

Embodiment 3

[0042] First, add refined glufosinate-ammonium hydrochloride (0.1mol) into 20ml of water, heat up to 60°C to dissolve it, cool down to 30°C, and add 7.3g of concentrated ammonia water with a concentration of 28% dropwise; then, stir at room temperature for 15 minutes, Cool down to -10°C, stir for 5 hours to crystallize, filter the precipitated crystals, wash with methanol and dry to obtain 16 g of refined glufosinate-ammonium monohydrate crystals with a yield of 80.4% and a purity of 97.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com