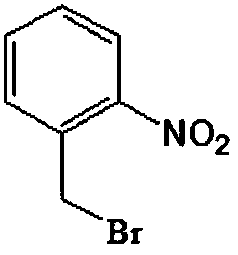

Preparation method of o-nitrobenzyl bromide

A technology of o-nitrobenzyl bromide and o-nitrotoluene, which is applied in the field of preparation of o-nitrobenzyl bromide, can solve the problems of low yield, high cost, and expensive raw materials, and achieve high reaction selectivity and low cost. Inexpensive and readily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

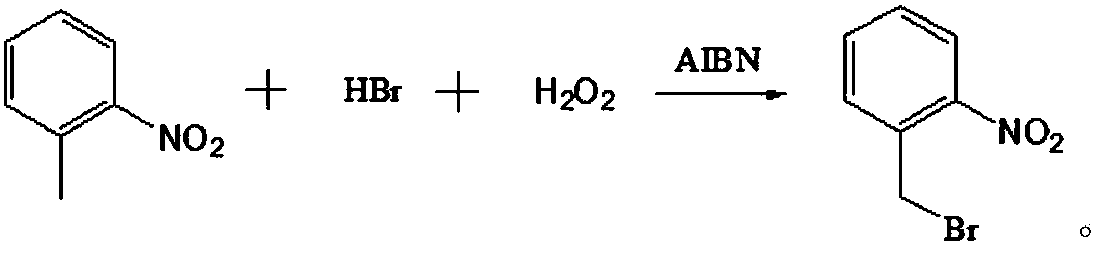

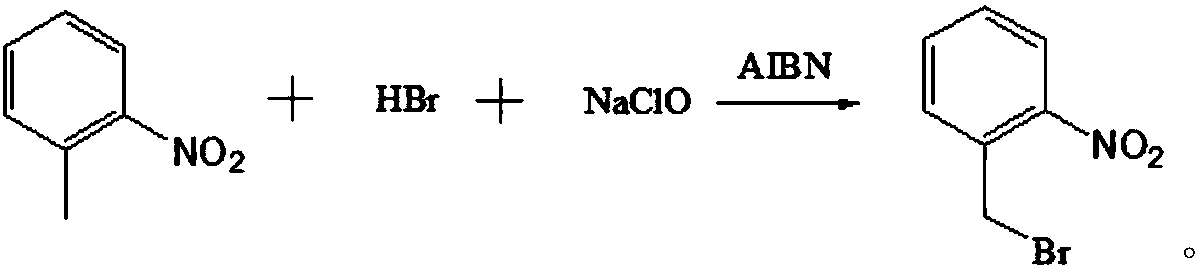

[0029] A preparation method of o-nitrobenzyl bromide, using o-nitrotoluene as a raw material, using NaClO / HBr as a bromination agent, and using azobisisobutyronitrile as an initiator to prepare by bromination reaction Ortho-nitrobenzyl bromide, comprising the following steps:

[0030] (1) Prepare the first mixed solution and the second mixed solution:

[0031] 206g dichloroethane is divided into two parts, respectively the first solvent 136g, the second solvent 70g; 2.5g azobisisobutyronitrile (AIBN) is divided into two parts, respectively the first initiator 0.5g, the second initiator Dose 2.0g.

[0032] With 41.2g (0.30mol) o-nitrotoluene, 136g dichloroethane (the first solvent), 54.6g hydrobromic acid solution (the mass concentration of hydrobromic acid in this solution is 40%, promptly contains 0.27mol in this solution hydrobromic acid) and 0.5g azobisisobutyronitrile (the first initiator) were mixed uniformly to obtain the first mixed solution.

[0033] Mix 2.0 g of az...

Embodiment 2

[0037] A preparation method of o-nitrobenzyl bromide, using o-nitrotoluene as a raw material, using NaClO / HBr as a bromination agent, and using azobisisobutyronitrile as an initiator to prepare by bromination reaction Ortho-nitrobenzyl bromide, comprising the following steps:

[0038] (1) Prepare the first mixed solution and the second mixed solution:

[0039] 247g dichloroethane is divided into two parts, respectively the first solvent 177g, the second solvent 70g; 3.5g azobisisobutyronitrile (AIBN) is divided into two parts, respectively the first initiator 0.5g, the second initiator Dose 3.0g.

[0040] With 41.2g (0.30mol) o-nitrotoluene, 177g dichloroethane (the first solvent), 50.6g hydrobromic acid solution (the mass concentration of hydrobromic acid in this solution is 48%, promptly contains 0.30mol hydrobromic acid) and 0.5g azobisisobutyronitrile (the first initiator) were mixed uniformly to obtain the first mixed solution.

[0041] 3.0 g of azobisisobutyronitrile ...

Embodiment 3

[0045] A preparation method of o-nitrobenzyl bromide, using o-nitrotoluene as a raw material, using NaClO / HBr as a bromination agent, and using azobisisobutyronitrile as an initiator to prepare by bromination reaction Ortho-nitrobenzyl bromide, comprising the following steps:

[0046] (1) Prepare the first mixed solution and the second mixed solution:

[0047] 230g carbon tetrachloride is divided into two parts, respectively the first solvent 160g, the second solvent 70g; 2.5g azobisisobutyronitrile (AIBN) is divided into two parts, respectively the first initiator 0.5g, the second initiator Dose 2.0g.

[0048] With 41.2g (0.30mol) o-nitrotoluene, 160g carbon tetrachloride (the first solvent), 66.7g hydrobromic acid solution (the mass concentration of hydrobromic acid in this solution is 40%, promptly contains 0.33mol in this solution hydrobromic acid) and 0.5g azobisisobutyronitrile (the first initiator) were mixed uniformly to obtain the first mixed solution.

[0049] 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com