Super-tonnage lifting extension and retraction system and control method for all-ground crane

A crane, all-terrain technology, used in cranes, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as poor cylinder synchronization, potential safety hazards, and unbalanced main boom load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

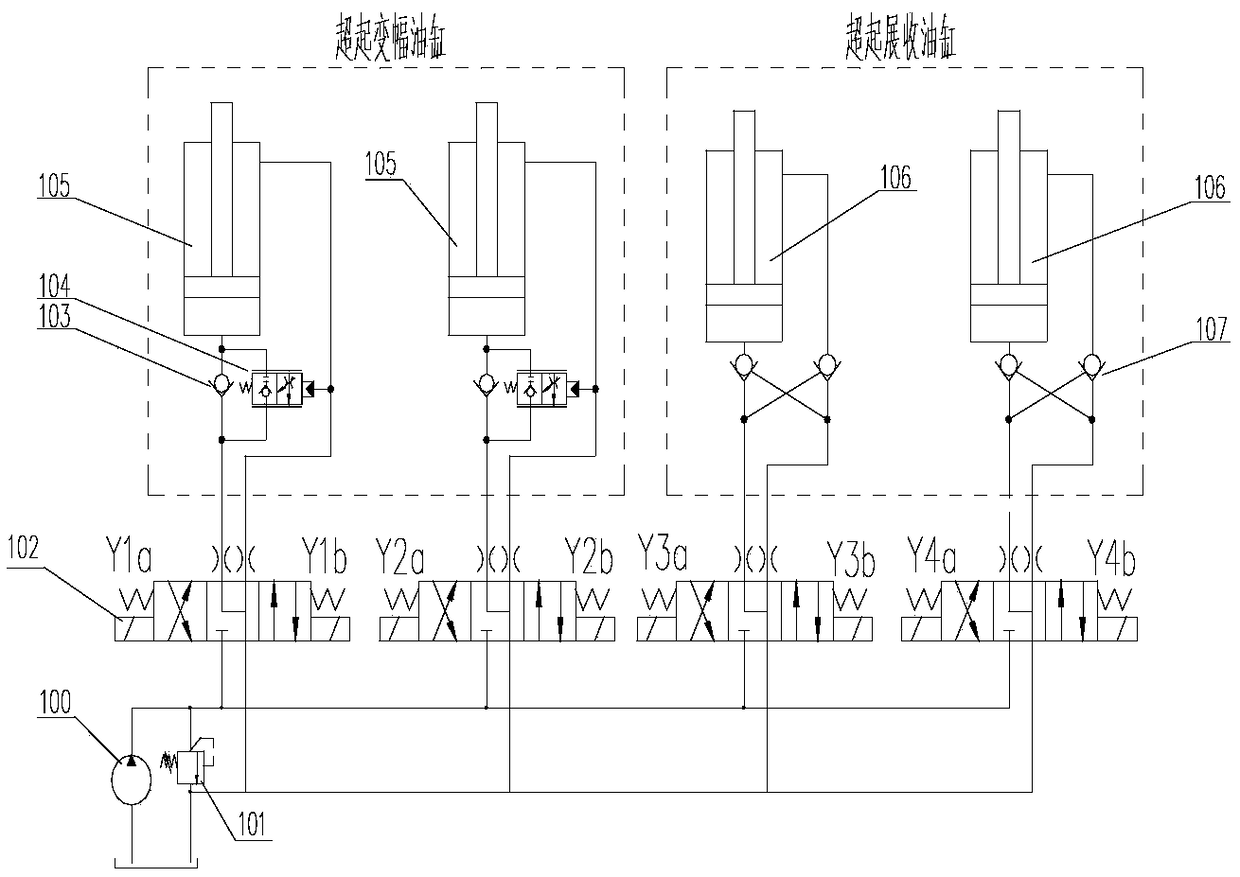

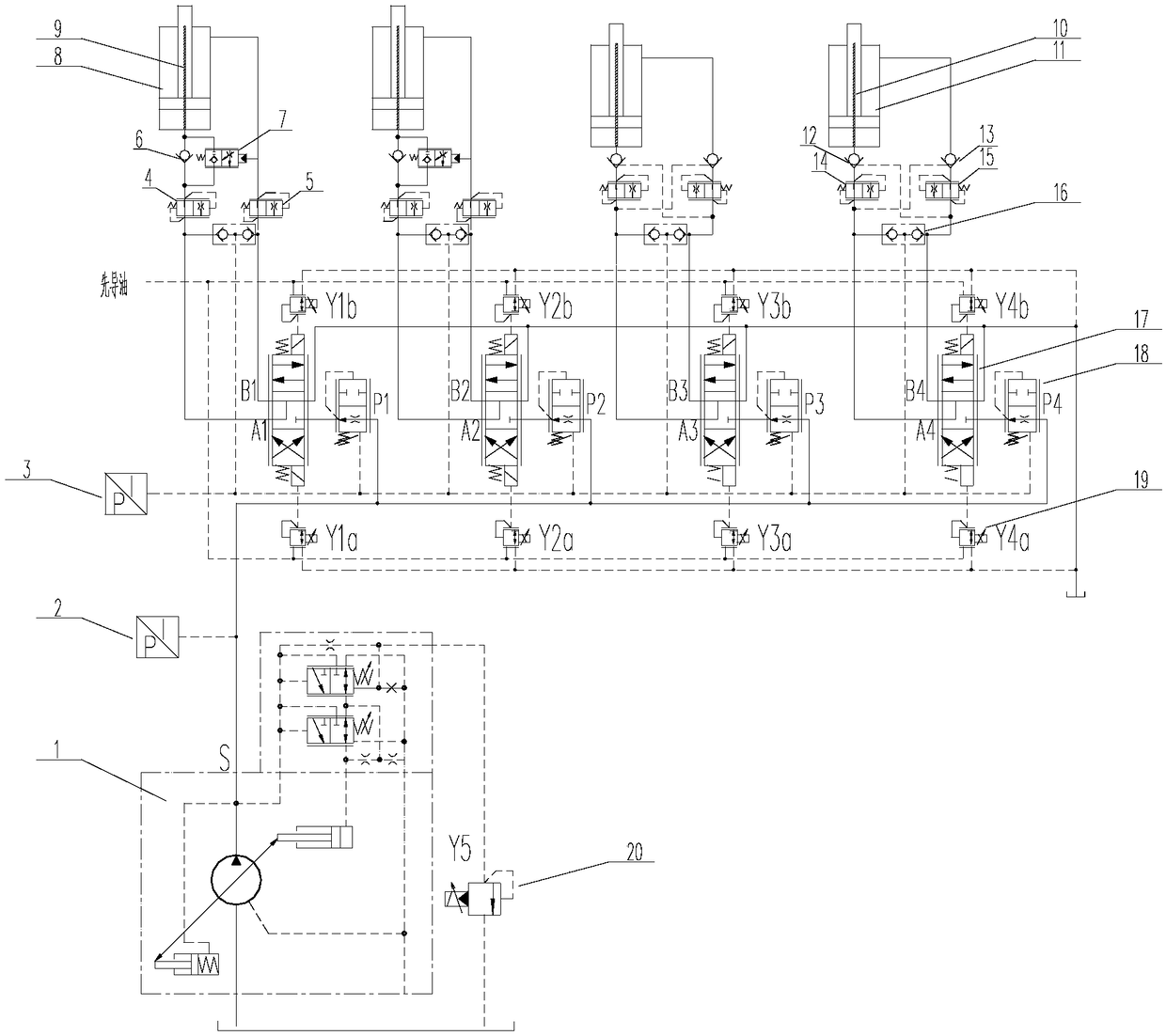

[0070] When the super-lift is inactive, all solenoid valves are not powered, the spool of the electric proportional relief valve only needs to overcome a small spring force, and the relief pressure is close to 0, and the constant pressure variable pump outputs with a very small pressure. , and the flow rate is almost 0 to reduce energy loss.

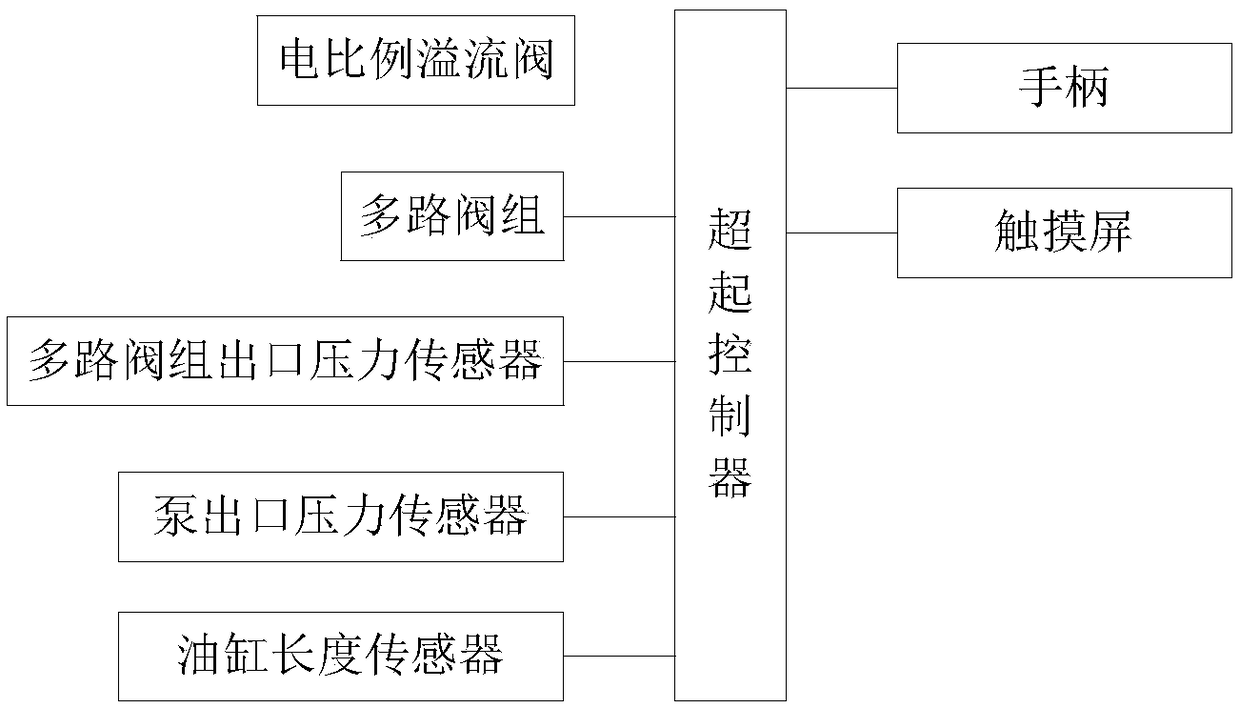

[0071] When super-lift action (luffing or expansion), the load pressure is fed back to the spring chamber of the pressure compensator through the pressure selection and feedback oil circuit, through the pressure compensator, the three-position four-way hydraulic control proportional valve in the multi-way valve group The pressure difference between the front and rear is constant, and the flow through the three-position four-way hydraulic control proportional valve corresponding to the multi-way valve is only related to the opening degree, that is, only related to the current of the electric proportional pressure reducing valve. If the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com