Hydraulic transmission method and device using boat diesel engine afterheat

A marine diesel engine and hydraulic transmission technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as unreasonable, insufficient utilization of waste heat from exhaust gas, etc., and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

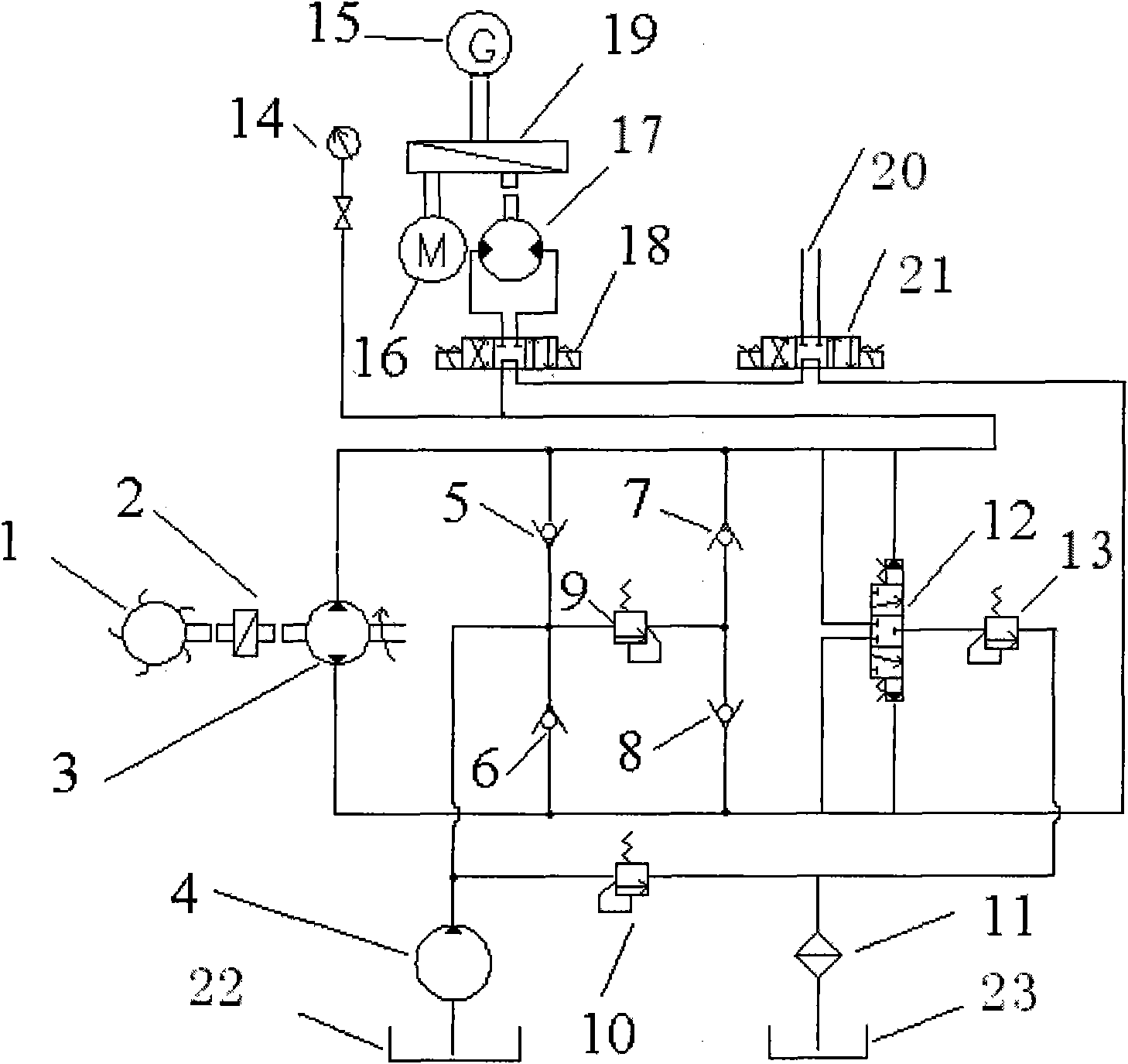

[0012] like figure 1 As shown, the waste gas in the exhaust gas turbocharging system of the diesel engine is led to the turbine 1 in the system through the bypass valve under the sailing condition of the ship, which drives the turbine 1 to rotate, and converts the heat energy contained in the exhaust gas into the mechanical energy of the system. Turn on the clutch 2, and the turbine 1 will drive the two-way variable pump 3 to rotate. According to the system requirements, the two-way variable pump 3 can output pressure oil to the hydraulic system in both directions to provide energy. If the system pressure is stably lower than the maximum limit pressure set by the system during the working process of the system, the system overload safety protection circuit will be closed and the system will work normally. The two-way variable pump 3 converts the energy converted by the turbine 1 into system pressure energy output, which can be respectively output to the two-way quantitative pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com