Ultrasonic roll welding and resistance internal heat composite metal seam welding device

A welding device and thermal composite technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being widely used, expensive welding equipment, assembly constraints and harsh joint forms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

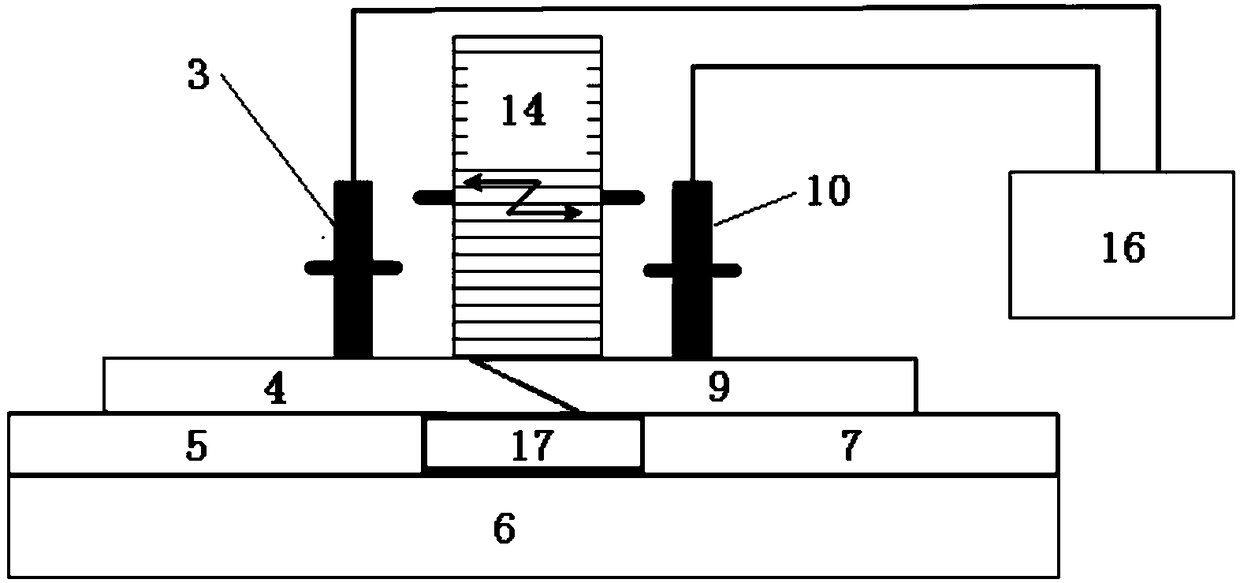

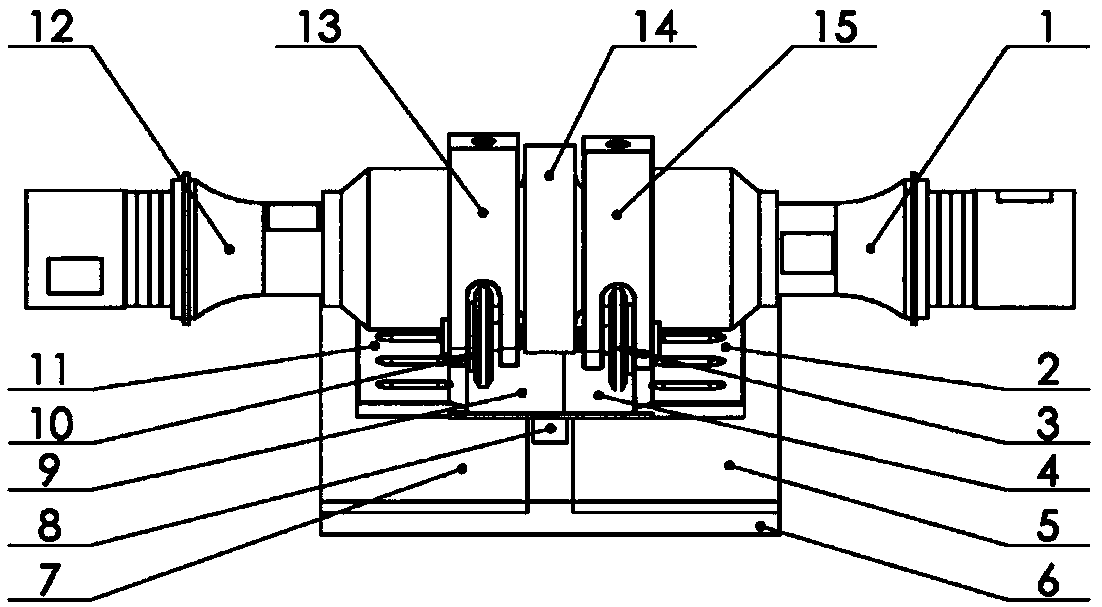

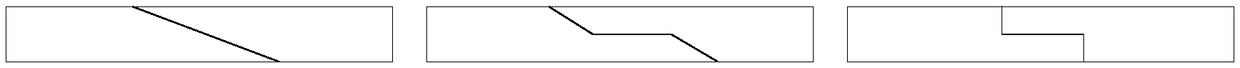

[0024] Taking aluminum alloy as an example, the welding principle is as follows: figure 1 As shown, the actual welding method is as follows image 3 As shown, the groove form is as image 3 As shown, the thickness of the aluminum alloy plate to be welded is 2 mm. During the welding process, the aluminum alloy plate is first installed on the workbench and fixed with flexible tooling. Turn on the power supply of the ultrasonic generator and the pulse heat-resistant equipment, set the ultrasonic welding parameters (power 3KW, amplitude 25μm, speed 8mm / s) and pulse heat-resistant equipment parameters (current 4KA), and the high-frequency current acts on the contact interface of the two metal plates The heating and softening of the interface metal is realized at the interface. After everything is ready, welding along the direction shown in the figure can obtain a high-quality solid-phase cold welding seam. In order to optimize the welding process, a low-melting point aluminum-sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com