Electrostatic fume purifying device with composite layer type electric field

An oil fume purification, electrostatic technology, applied in electrode conveying device, electrostatic separation, electrode structure and other directions, can solve the problems of insufficient effective stun area, small number of stun electrodes, short oil fume residence time, etc., to improve the effect of oil fume purification , Good fume purification effect, prolonging the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

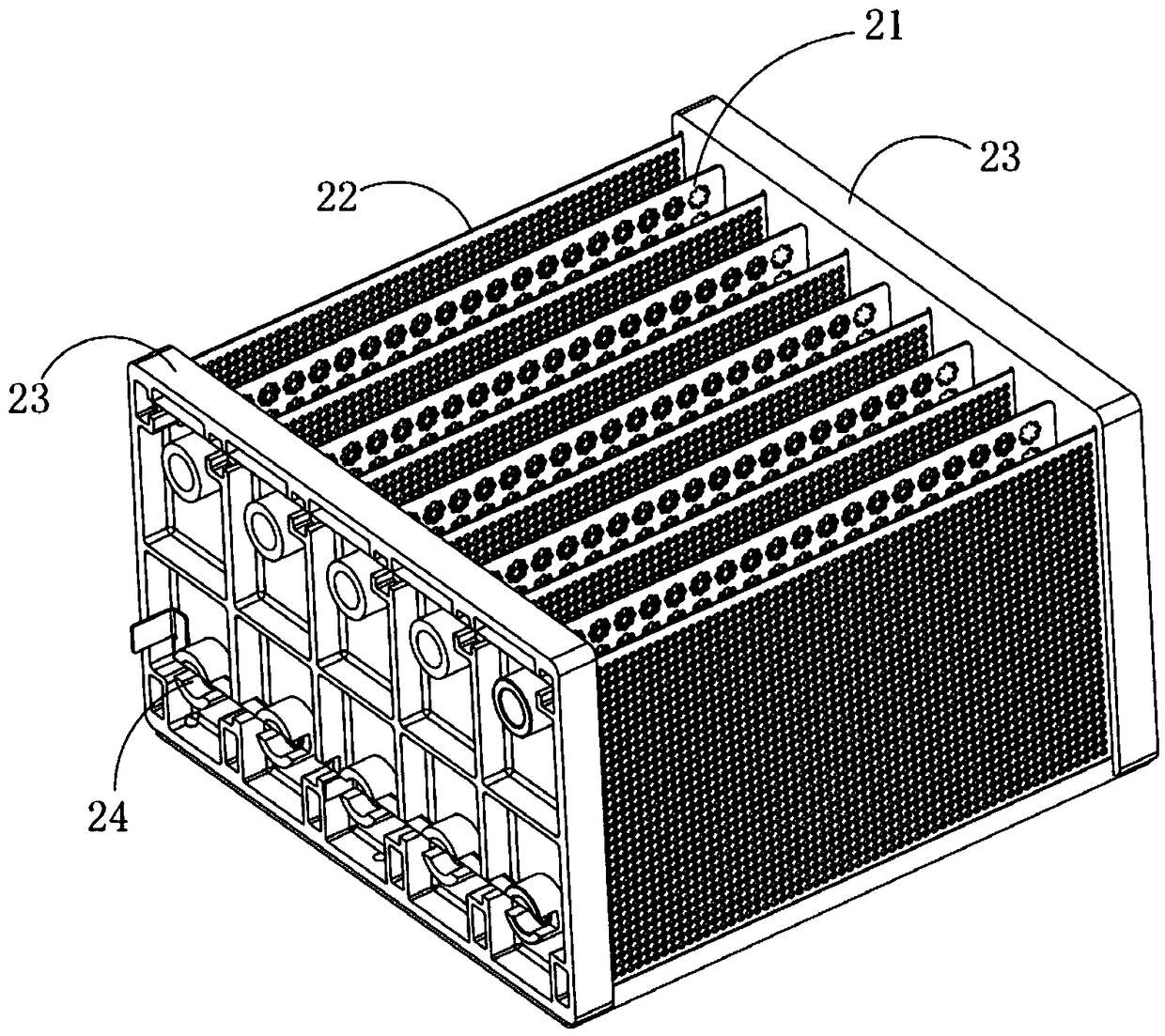

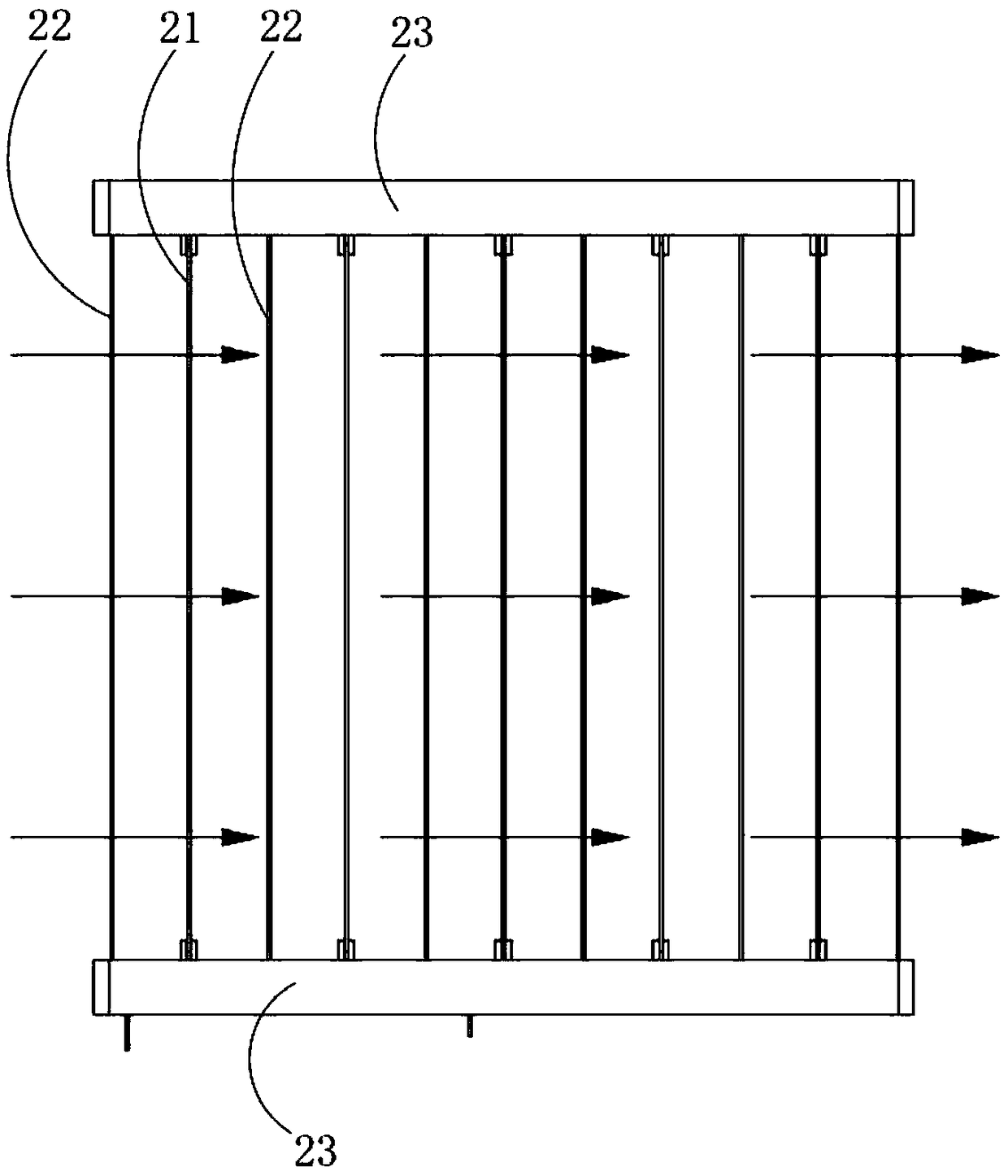

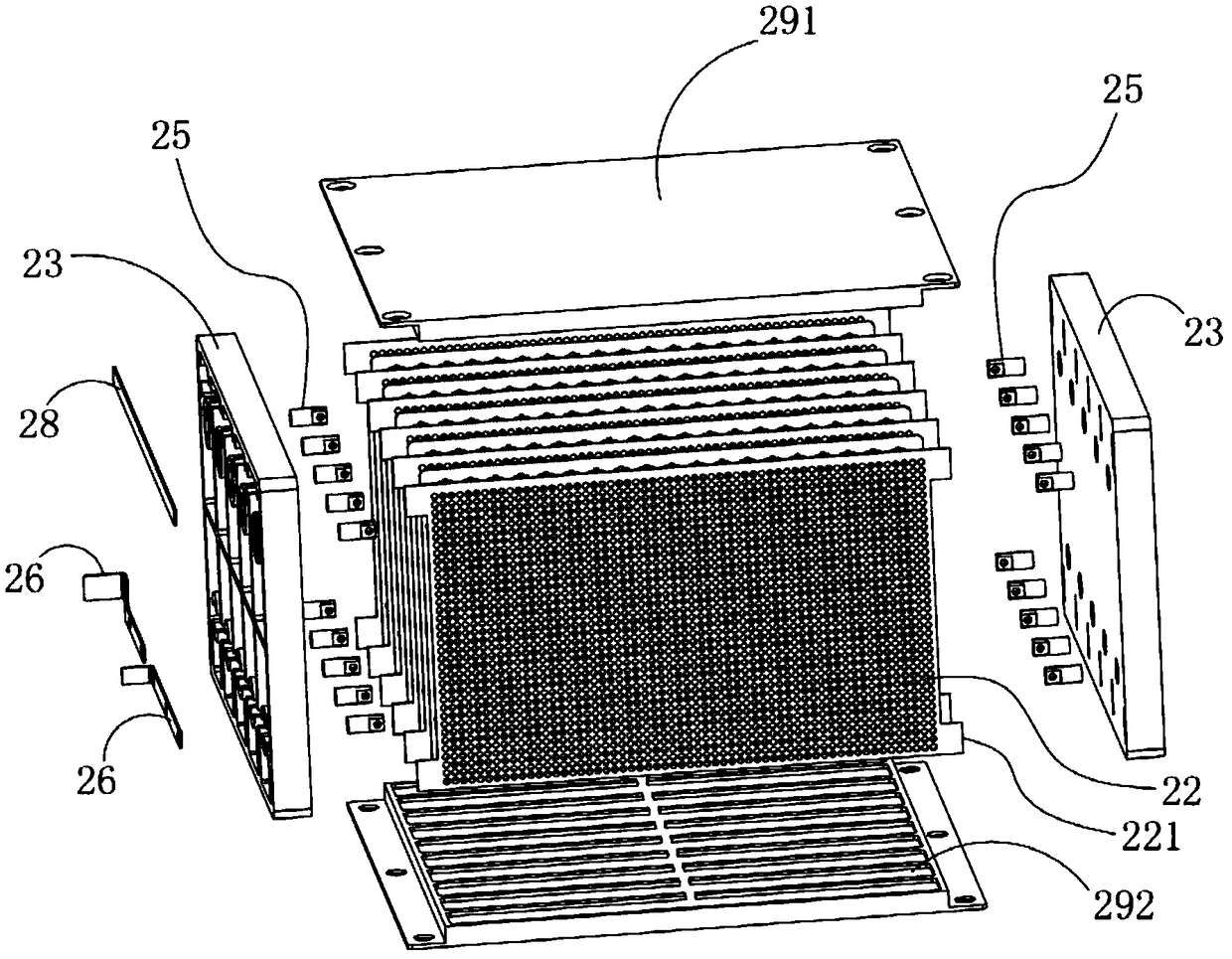

[0030] An electrostatic oil fume purification device with a composite layer electric field, such as Figure 1 to Figure 5 As shown, a box is included, one end of the box is provided with an air inlet, the other end of the box is provided with an air outlet, and at least one high-voltage electrostatic field group is arranged in the box, and the high-voltage electrostatic field group includes at least one cathode plate 21 and at least one An anode plate 22, all cathode plates 21 and anode plates 22 are alternately stacked and installed in the casing along the airflow direction, each cathode plate 21 is provided with a plurality of corona opening holes 211, and the edge of each corona opening hole 211 is convex At least one corona electrode 212 is molded; each anode plate 22 is provided with a plurality of ventilation holes. Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com