Preparation method of porous calcium alginate gel spheres for treating heavy metal sewage

A calcium alginate gel ball and sewage treatment technology, applied in the field of preparation of polymer porous materials, can solve the problems of large pore size uniformity, small specific surface area, affecting the adsorption effect of heavy metal ions, etc., and achieve the effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

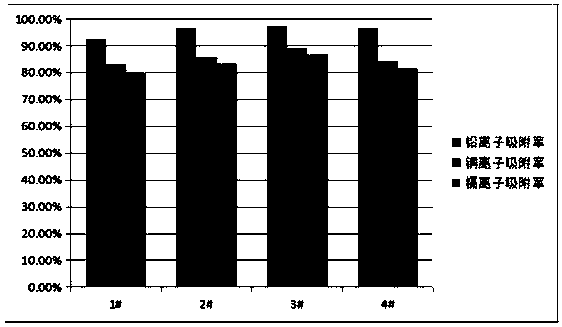

Embodiment 1

[0044] 20g of deionized water and 0.2g of sodium alginate were added into a 100ml beaker and stirred on a stirrer for 6h to form a 1% sodium alginate solution.

[0045] 0.05 g of 2% polystyrene microsphere emulsion was added to the above sodium alginate solution to form a mixed solution, the particle diameter of the microspheres was about 600 nm, and the mixed solution was placed on a stirrer and stirred for 6 hours.

[0046] The above homogeneous mixed solution was added dropwise into 0.2M calcium chloride solution with a dropper, and the formed gel balls were washed 3 times with deionized water and then put into a low-temperature refrigerator for freezing for 12 hours.

[0047] Put the frozen samples above into a vacuum freeze dryer for vacuum freeze drying for 48 hours, and then obtain porous calcium alginate gel balls. The obtained sample is marked as 2#.

Embodiment 2

[0049] Add 0.1g 2% polystyrene microsphere emulsion to the 1% sodium alginate solution configured in Example 1 to form a mixed solution, the particle diameter of the microsphere is about 600nm, and the mixed solution is placed on a stirrer to stir 6h.

[0050] The above homogeneous mixed solution was added dropwise into 0.2M calcium chloride solution with a dropper, and the formed gel balls were washed 3 times with deionized water and then put into a low-temperature refrigerator for freezing for 12 hours.

[0051] Put the frozen samples above into a vacuum freeze dryer for vacuum freeze drying for 48 hours, and then obtain porous calcium alginate gel balls. The obtained sample is marked as 3#.

Embodiment 3

[0053] Add 0.5 g of 2% polystyrene microsphere emulsion to the 1% sodium alginate solution configured in Example 1 to form a mixed solution with a particle diameter of about 600 nm, and place the mixed solution on a stirrer to stir for 6 h .

[0054] The above homogeneous mixed solution was added dropwise into 0.2M calcium chloride solution with a dropper, and the formed gel balls were washed 3 times with deionized water and then put into a low-temperature refrigerator for freezing for 12 hours.

[0055] Put the frozen samples above into a vacuum freeze dryer for vacuum freeze drying for 48 hours, and then obtain porous calcium alginate gel balls. The obtained sample is marked as 4#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com