Multifunctional integrated all-in-one machine for core processing and method adopting same

A multi-function, all-in-one technology, applied in the field of geological exploration equipment, to achieve the effect of reducing work intensity, saving work time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

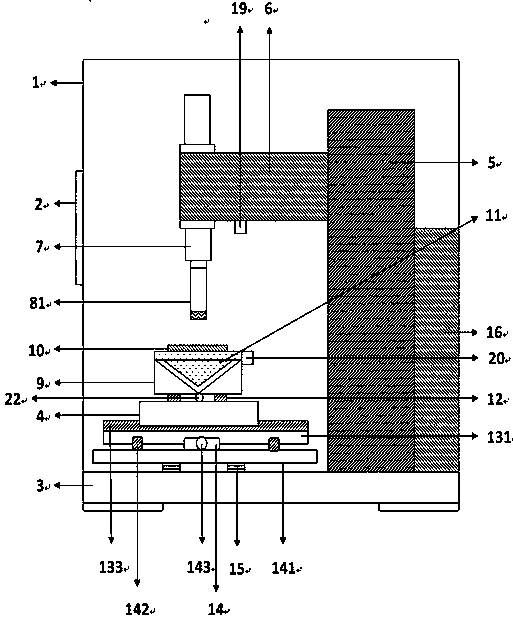

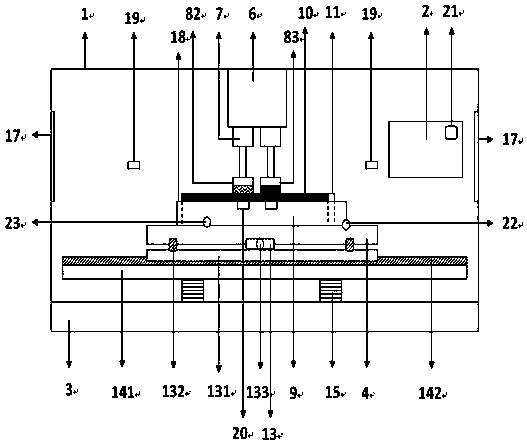

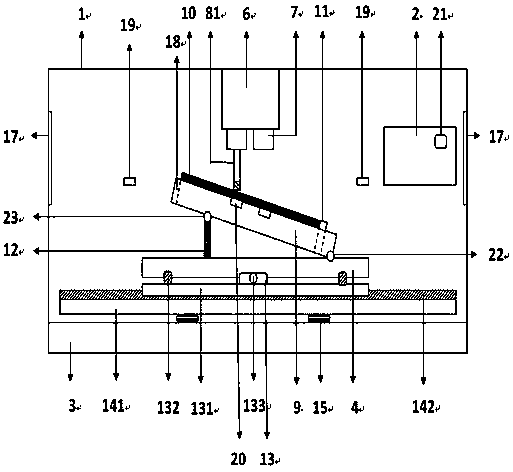

[0041] Example 1. Such as Figure 1-2 , 4, and 5, the integrated machine includes a main machine tool, a core clamping device, a cooling device, and a full servo control device.

[0042] Described main machine tool comprises base 3, workbench 4, column 5, spindle box 6, column 5 is fixed on the base 3, and spindle box 6 is installed on the front side of the top of column 5. The headstock 6 is arranged vertically, that is, arranged in the direction of the Y axis. Two rotatable main shafts 7 are vertically arranged on the spindle box 6, and a drilling and grinding tool 8 is provided on the bottom of each main shaft 7; One of them; the workbench 4 is installed on the base 3 below the drilling and grinding tool 8 in front of the column 5 through a moving device that can control the movement of the workbench 4 in the X-axis, Y-axis, and Z-axis directions, wherein the front and rear movement is the Y axis, Moving left and right is the X axis, and moving up and down is the Z axis....

Embodiment 2

[0069]Example 2. The multifunctional core processing integrated machine is composed of main machine tool, drilling and grinding tool device, core holding device, liquid nitrogen cooling device, full servo control device and auxiliary safety device. The overall shell is made of stainless steel.

[0070] The main machine tool is composed of body, base, workbench, column, spindle box and so on. The body is fixed on the base to install and support the various parts of the machine tool. The workbench is driven by the longitudinal feed servo motor, horizontal feed servo motor and vertical lift feed servo motor to complete the feed of X, Y, and Z coordinates. , the front and rear movement is the Y axis, the left and right movement is the X axis, and the up and down movement is the Z axis. The horizontal movement of the worktable can reach a displacement space of more than one meter. The headstock is fixed on the column, and the headstock is equipped with double spindles, and suitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com