Down-the-hole drill with dustproof function and use method thereof

A down-the-hole drilling rig and functional technology, applied in drilling equipment and methods, reciprocating drilling rigs, earth-moving drilling, etc., can solve the problems of poor flexibility, difficult dust removal, fixed mast angle, etc. Guarantee and speed up the effect of the project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

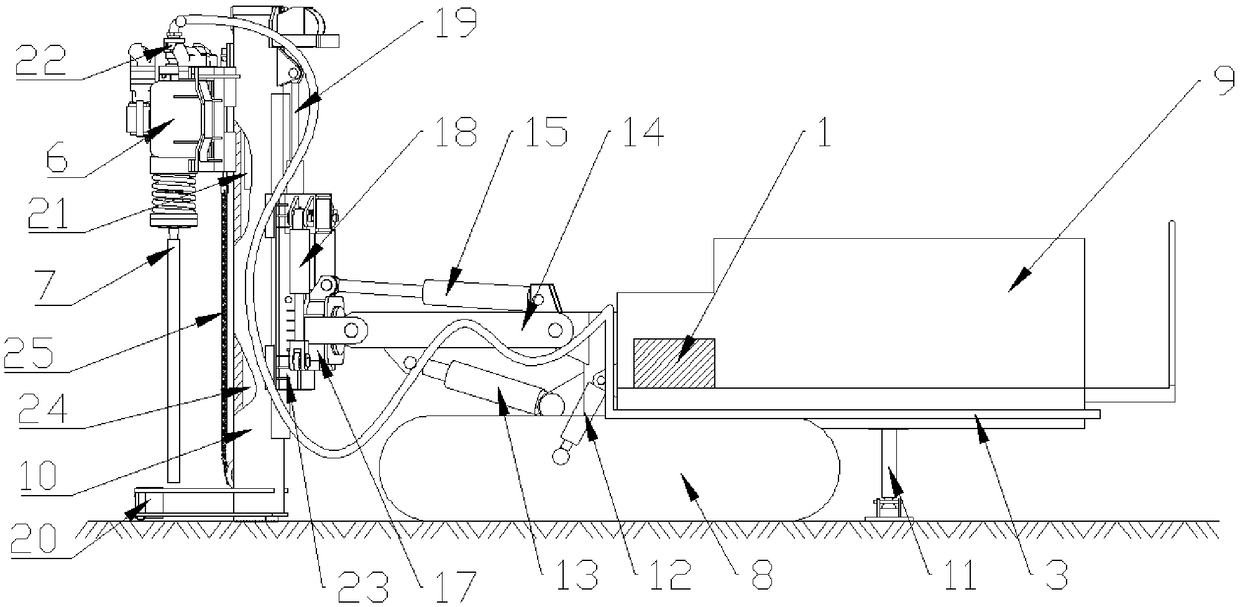

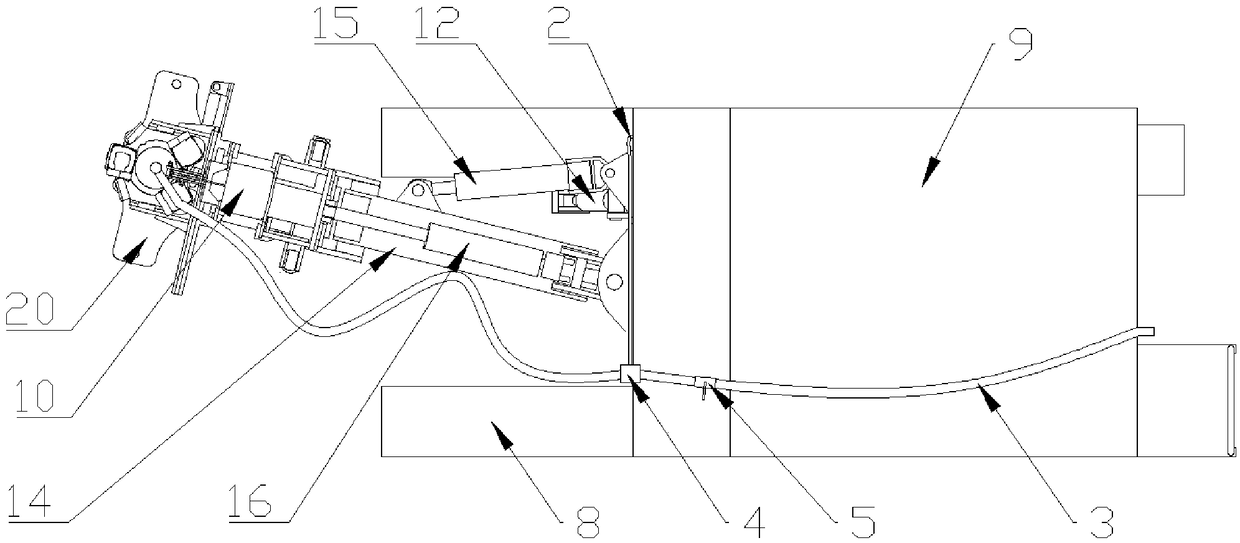

[0041] Such as figure 1 with 2 As shown, it includes: a drilling mechanism, a dust removal mechanism, a high-pressure air pipe 3, and a base 9. The drilling mechanism includes a drill power head 6 and a hollow drill rod 7. The housing of the drill power head 6 is connected to the drill mast through a fixed seat 10. The hollow drill rod 7 is connected to the output end of the drill power head 6, one end of the high pressure air pipe 3 is connected with a high pressure air pump, and the other end of the high pressure air pipe 3 is connected to the hollow drill rod 7 through the drill power head 6. The dust removal mechanism includes a high-pressure water pump 1 and a high-pressure water pipe 2. One end of the high-pressure water pipe 2 is connected to the high-pressure water pump 1, the other end of the high-pressure water pipe 2 is connected to the high-pressure gas pipe 3 through a three-way joint 4, and the high-pressure gas pipe 3 is connected with a manual switch valve 5. The...

Embodiment 2

[0044] Such as figure 1 with 2 As shown, it includes: a drilling mechanism, a dust removal mechanism, a high-pressure air pipe 3, and a base 9. The drilling mechanism includes a drill power head 6 and a hollow drill rod 7. The housing of the drill power head 6 is connected to the drill mast through a fixed seat 10. The hollow drill rod 7 is connected to the output end of the drill power head 6, one end of the high pressure air pipe 3 is connected with a high pressure air pump, and the other end of the high pressure air pipe 3 is connected to the hollow drill rod 7 through the drill power head 6. The dust removal The mechanism includes a high-pressure water pump 1 and a high-pressure water pipe 2. One end of the high-pressure water pipe 2 is connected to the high-pressure water pump 1, the other end of the high-pressure water pipe 2 is connected to the high-pressure gas pipe 3 through a three-way joint 4, and the high-pressure gas pipe 3 is connected with a manual switch valve 5 ...

Embodiment 3

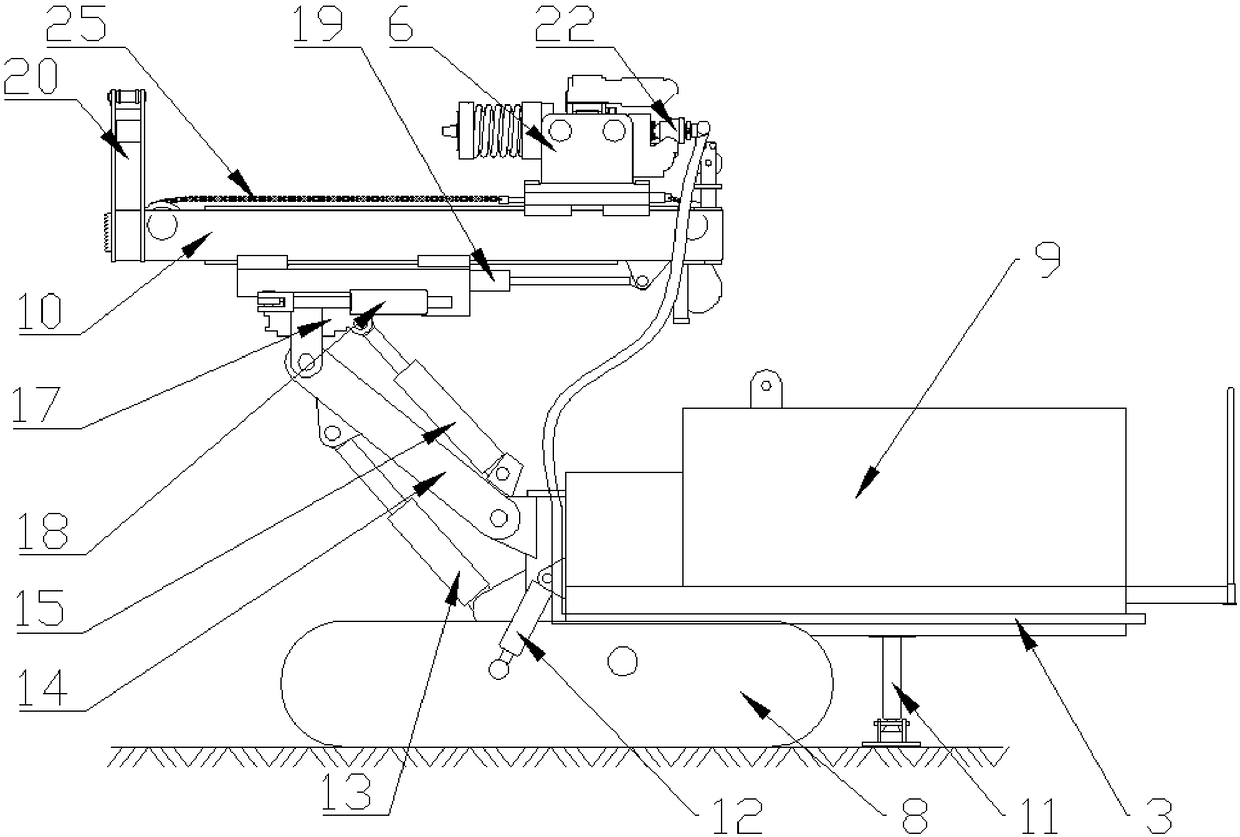

[0053] Such as figure 1 with 4 As shown, it includes: a drilling mechanism, a dust removal mechanism, a high-pressure air pipe 3, and a base 9. The drilling mechanism includes a drill power head 6 and a hollow drill rod 7. The housing of the drill power head 6 is connected to the drill mast through a fixed seat 10. The hollow drill rod 7 is connected to the output end of the drill power head 6, one end of the high pressure air pipe 3 is connected with a high pressure air pump, and the other end of the high pressure air pipe 3 is connected to the hollow drill rod 7 through the drill power head 6. The dust removal The mechanism includes a high-pressure water pump 1 and a high-pressure water pipe 2. One end of the high-pressure water pipe 2 is connected to the high-pressure water pump 1, the other end of the high-pressure water pipe 2 is connected to the high-pressure gas pipe 3 through a three-way joint 4, and the high-pressure gas pipe 3 is connected with a manual switch valve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com