A pipe multi-angle drilling equipment

A kind of drilling equipment, multi-angle technology, applied in the direction of drilling/drilling equipment, metal processing equipment, boring machine/drilling machine parts, etc., can solve the problems of low drilling accuracy, inconvenient processing, inconvenient distance control, etc. , to achieve the effect of improving drilling accuracy, improving drilling efficiency, and controlling drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

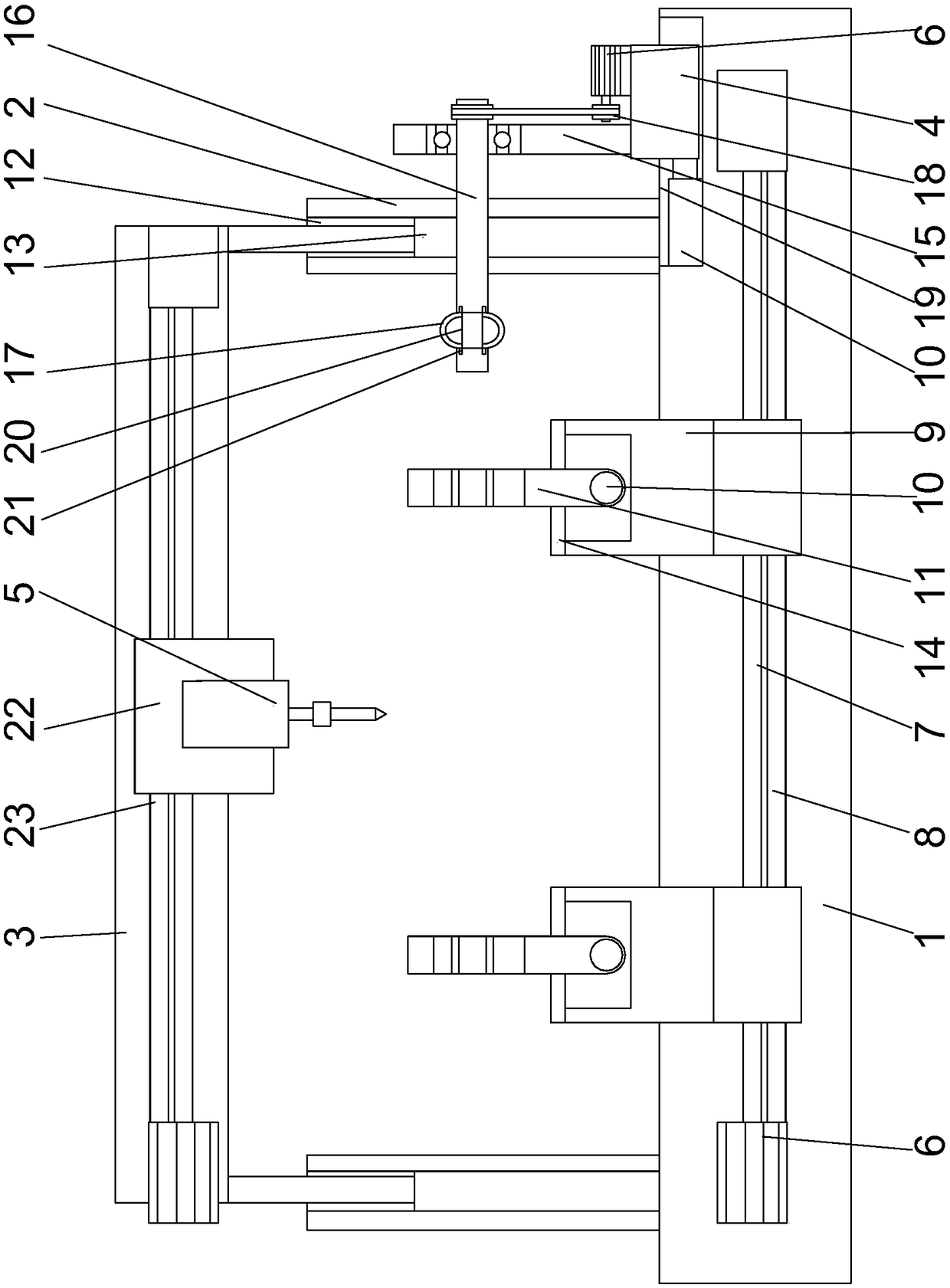

Embodiment 1

[0023] Such as figure 1 As shown, a pipe multi-angle drilling equipment includes a base 1 and a beam 3 arranged on the base, the beam is provided with a drilling device 5, and a pipe rotation device is provided on the base , a motor 6 is arranged on the base, a lead screw 7 is arranged on the rotating shaft of the motor, a fixed shaft 8 matched with the lead screw is arranged below the lead screw, and a A support platform 9 is provided on the bar, and the support platform is sleeved on the lead screw and the fixed shaft, and two hydraulic cylinders 10 arranged opposite to each other are arranged on the support platform. The expansion rods of the hydraulic cylinders are respectively provided with positioning buckles 11, the lower ends of the positioning buckles are fixedly connected to the hydraulic cylinders, the upper ends of the positioning buckles are semicircular, and the upper ends of the two hydraulic cylinders A circular structure is formed between the positioning buck...

Embodiment 2

[0031] In this embodiment, on the basis of Embodiment 1, in order to realize the rotation of the crossbar conveniently, preferably, a motor 6 and a reduction box matched with the motor are arranged on the upper end surface of the slider. The output shaft of the reduction box is provided with a pulley 18, and one end of the said cross bar protruding from the support is provided with a pulley, and the said reduction case drives the said cross bar to rotate by a belt. The belt pulley is driven to rotate by the motor, and the power transmission is realized by the belt, which drives the cross bar to rotate relative to the bracket. When the pipe needs to be rotated, slide the slider along the base, so that the slider drives the bracket to move towards the pipe. When the buckle on the cross bar is engaged with the inner side of the pipe, the starting motor drives the cross bar to rotate, so that the pipe rotates accordingly.

[0032]In this embodiment, in order to facilitate the move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com