Drilling machine for machining and using method thereof

A technology of mechanical processing and drilling machine, applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of tediousness, large device size, inability to use various bottom surfaces, etc. , to achieve the effect of good practicability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

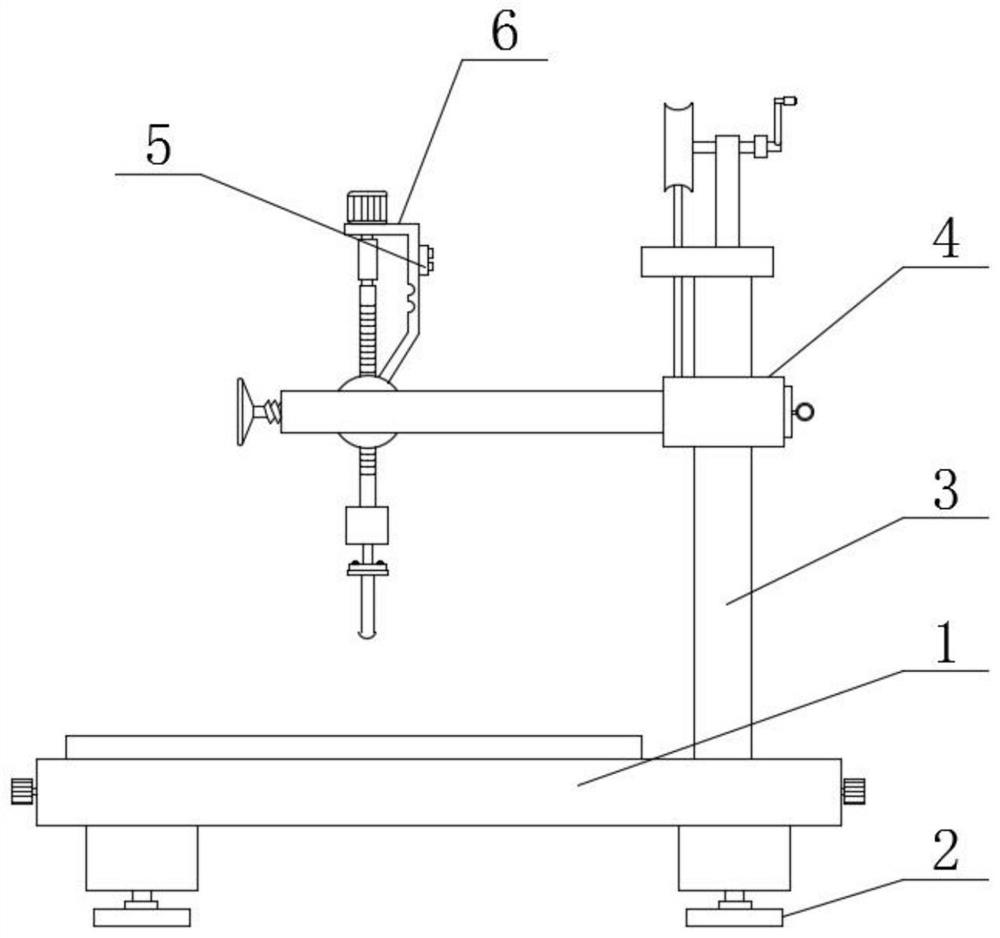

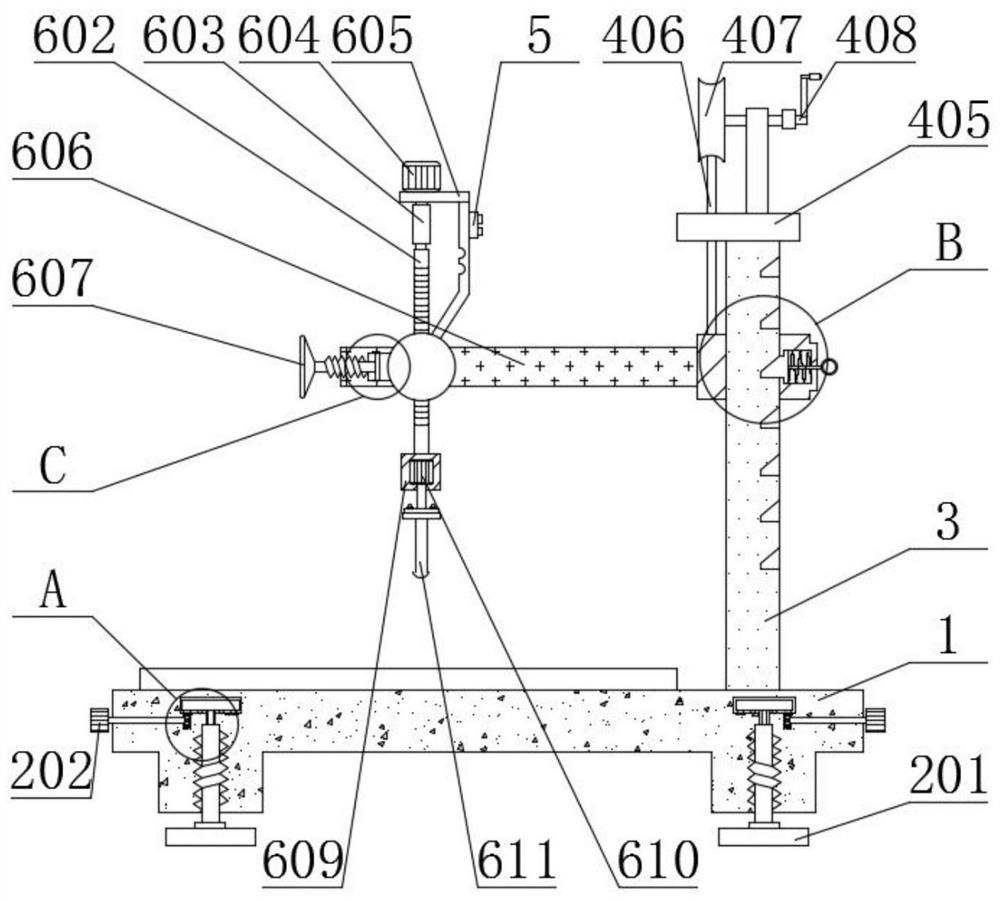

[0032] see Figure 1-7 , the present invention provides a technical solution:

[0033] A drilling machine for mechanical processing, comprising a base 1 and a controller 5, a base flatness adjustment mechanism 2 is provided at the inner four corners of the base 1, a support column 3 is fixedly connected to the right side of the top of the base 1, and the outer side of the support column 3 A height adjustment mechanism 4 is provided. The height adjustment mechanism 4 includes a horizontal plate 606. The left end of the horizontal plate 606 is provided with a drilling mechanism 6. The base flatness adjustment mechanism 2 includes a rotating hand 202 and a turntable 203. The rotation of the turntable 203 is set on the bottom of the base 1. On the inner side, the bottom end of the turntable 203 is fixedly connected with a gear ring 205, and the central position of the bottom end of the turntable 203 is fixedly connected with an inner rod 206. 208, the inner side of the base 1 is ...

Embodiment 2

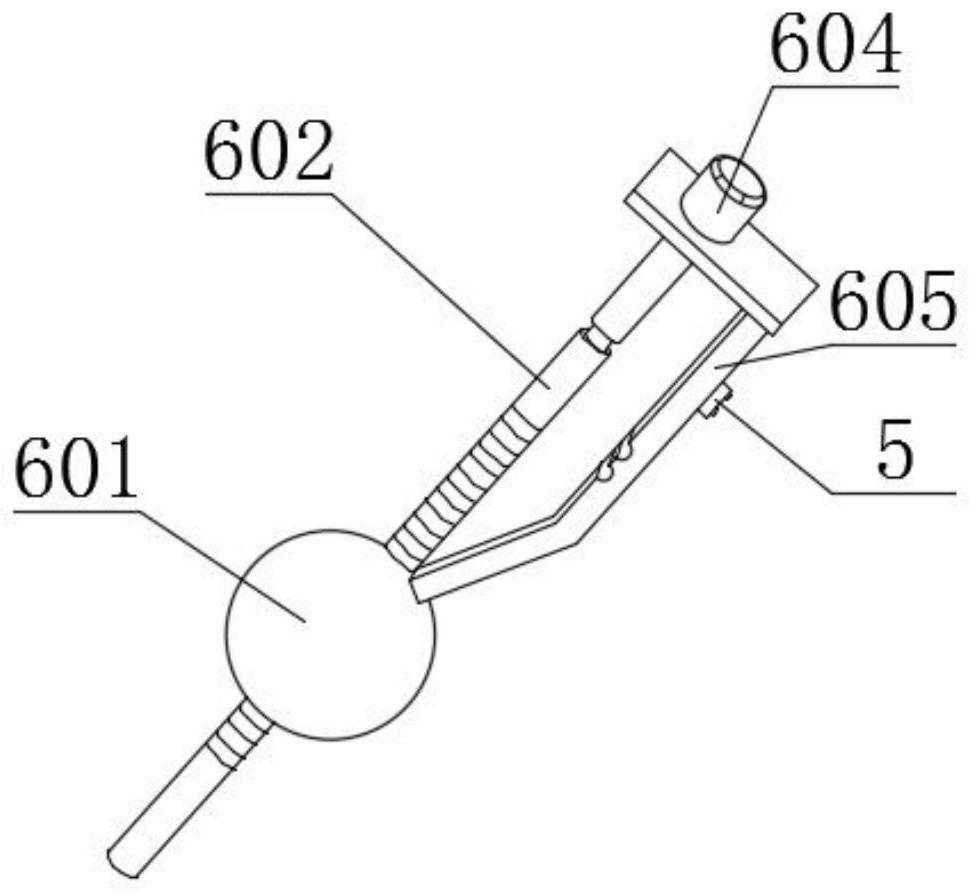

[0038] Workflow: The same parts in this embodiment as in Embodiment 1 will not be repeated, the difference is that the present invention can also realize the adjustment of the drilling angle, when adjusting, the staff can hold the support frame 605 with their hands, Rotate the compression screw 607, and the compression screw 607 will drive the rubber pad 608 to rotate left or right during the rotation process. When the rubber pad 608 moves to the left for a certain distance, the staff can adjust the support frame 605 and press Under the action of the rotating ball 601, the angle of the drilling head 611 is changed. After adjusting to the required angle, turn the compression screw 607 again to keep the rubber pad 608 and the rotating ball 601 in close contact, thereby realizing counter-rotating balls. The fixing of the angle between 601 and drilling head 611 has good practicability. After fixing, the staff can control the first motor 604 to rotate through the controller 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com