345 MPa-grade low-cost high-toughness steel sheet and production method thereof

A production method and low-cost technology, applied in the field of metallurgy, can solve the problems of reduced toughness and deterioration of steel plate welding performance, and achieve the effects of good low-temperature impact toughness, reduced alloy cost and production cost, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

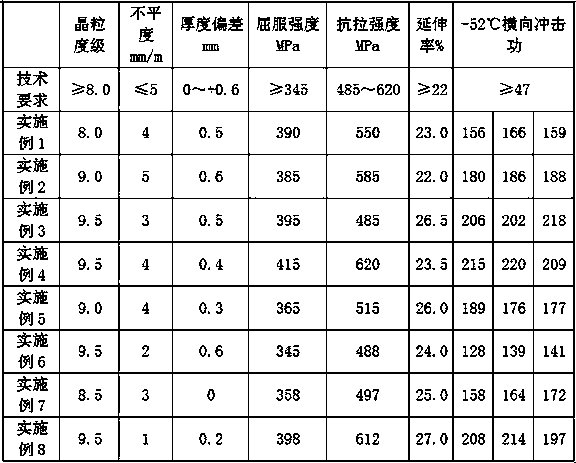

Examples

Embodiment 1

[0018] The thickness specification of the 345MPa low-cost high-toughness steel plate in this embodiment is 20mm, and its chemical composition and mass percentage are: C: 0.13%, Si: 0.40%, Mn: 1.48%, P: 0.012%, S: 0.006% , Al: 0.035%, Nb: 0.030%, the balance is Fe and unavoidable impurities.

[0019] The production method of the 345MPa grade low-cost high-toughness steel plate of this embodiment includes steel billet heating, controlled rolling, post-rolling cooling, and steel plate straightening processes. The specific process steps are as follows:

[0020] (1) Billet heating process: the maximum billet heating temperature is 1260°C, the soaking temperature is 1240°C, the heating time is 11min / cm, of which the soaking time is 60min, and the billet thickness is 200mm;

[0021] (2) Controlled rolling process: a two-stage rolling process is adopted; the starting temperature of the first stage is 1080°C; the starting temperature of the second stage is 850°C, the final rolling temp...

Embodiment 2

[0026] The thickness specification of the 345MPa low-cost high-toughness steel plate in this embodiment is 30mm, and its chemical composition and mass percentage are: C: 0.14%, Si: 0.30%, Mn: 1.45%, P: 0.009%, S: 0.005% , Al: 0.020%, Nb: 0.033%, the balance is Fe and unavoidable impurities.

[0027] The production method of the 345MPa grade low-cost high-toughness steel plate of this embodiment includes steel billet heating, controlled rolling, post-rolling cooling, and steel plate straightening processes. The specific process steps are as follows:

[0028] (1) Billet heating process: the highest billet heating temperature is 1255°C, the soaking temperature is 1230°C, the heating time is 11min / cm, of which the soaking time is 65min, and the billet thickness is 200mm;

[0029] (2) Controlled rolling process: Two-stage rolling process is adopted; the starting temperature of the first stage is 1100°C; the starting temperature of the second stage is 860°C, the final rolling temper...

Embodiment 3

[0034] The thickness specification of the 345MPa low-cost high-toughness steel plate in this embodiment is 35mm, and its chemical composition and mass percentage are: C: 0.15%, Si: 0.20%, Mn: 1.50%, P: 0.008%, S: 0.003% , Al: 0.025%, Nb: 0.035%, the balance is Fe and unavoidable impurities.

[0035] The production method of the 345MPa grade low-cost high-toughness steel plate of this embodiment includes steel billet heating, controlled rolling, post-rolling cooling, and steel plate straightening processes. The specific process steps are as follows:

[0036] (1) Billet heating process: the highest billet heating temperature is 1250°C, the soaking temperature is 1230°C, the heating time is 12min / cm, of which the soaking time is 65min, and the billet thickness is 250mm;

[0037] (2) Controlled rolling process: a two-stage rolling process is adopted; the starting temperature of the first stage is 1130°C; the starting temperature of the second stage is 850°C, the final rolling temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com