Method for preparing ferronickel alloy utilizing low-grade laterite nickel ore

A technology of laterite nickel ore and nickel-iron alloy, which is applied in the field of preparation of nickel-iron alloy to achieve the effect of low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: The low-grade laterite nickel ore powder in this example is a certain laterite nickel ore in Yunnan. In terms of mass percentage, the low-grade laterite nickel ore powder contains Ni 0.93%, Fe 11.63%, MgO 28.70%, SiO 2 36.71%;

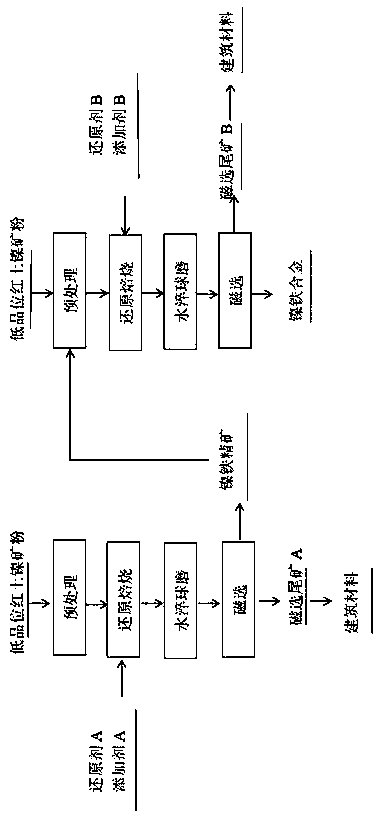

[0020] like figure 1 Shown, a kind of method utilizing low-grade laterite nickel ore to prepare nickel-iron alloy, concrete steps are as follows:

[0021] (1) The low-grade laterite nickel ore is dried, crushed to a particle size of -0.074mm, accounting for more than 75%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder;

[0022] (2) Mix the low-grade laterite nickel ore powder in step (1), reducing agent A (reducing agent A is coal powder), additive A (additive A is NaCl), and prepare pellets A with a diameter of 40mm, wherein The mass ratio of low-grade laterite nickel ore powder, reducing agent A (coal powder), and additive A (NaCl) is 1:0.07:0.08; at a temperature of 1250°C, pellet A is obtaine...

Embodiment 2

[0025] Example 2: The low-grade laterite nickel ore powder in this example is a certain laterite nickel ore in Yunnan. In terms of mass percentage, the low-grade laterite nickel ore powder contains Ni 0.93%, Fe 11.63%, MgO 28.70%, SiO 2 36.71%;

[0026] like figure 1 Shown, a kind of method utilizing low-grade laterite nickel ore to prepare nickel-iron alloy, concrete steps are as follows:

[0027] (1) The low-grade laterite nickel ore is dried, crushed to a particle size of -0.074mm, accounting for more than 75%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder;

[0028] (2) Mix the low-grade laterite nickel ore powder in step (1), reducing agent A (reducing agent A is coal powder), additive A (additive A is NaCl) and prepare pellets A with a diameter of 20mm, wherein The mass ratio of low-grade laterite nickel ore powder, reducing agent A (coal powder), and additive A (NaCl) is 1:0.1:0.1; at a temperature of 1180°C, pellet A is obtained b...

Embodiment 3

[0031] Example 3: The low-grade laterite nickel ore powder in this example is a certain laterite nickel ore in Yunnan. In terms of mass percentage, the low-grade laterite nickel ore powder contains Ni 1.2%, Fe 9.7%, MgO 31.5%, SiO 2 37.4%;

[0032] like figure 1 Shown, a kind of method utilizing low-grade laterite nickel ore to prepare nickel-iron alloy, concrete steps are as follows:

[0033] (1) The low-grade laterite nickel ore is dried, crushed to a particle size of -0.074mm, accounting for more than 75%, and passed through a 200-mesh sieve to obtain low-grade laterite nickel ore powder;

[0034] (2) Combine step (1) low-grade lateritic nickel ore powder, additive A (additive A is Na 2 SO 4 ) mixed evenly and prepared into a pellet A with a ball diameter of 30mm, in which low-grade laterite nickel ore powder, reducing agent A (coal powder), additive A (Na 2 SO 4) with a mass ratio of 1:0.1:0.07; at a temperature of 1230°C and the introduction of reducing agent A (red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com