Antibacterial nanometer polyurethane emulsion with air purification function, method for preparing same and carpentry paint

A polyurethane emulsion and air purification technology, applied in polyurea/polyurethane coatings, biocide-containing paints, coatings, etc., can solve the problem of inability to demonstrate the effect of formaldehyde absorption and decomposition, and achieve the improvement of the antibacterial effect of the emulsion and the hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4、 comparative example 1

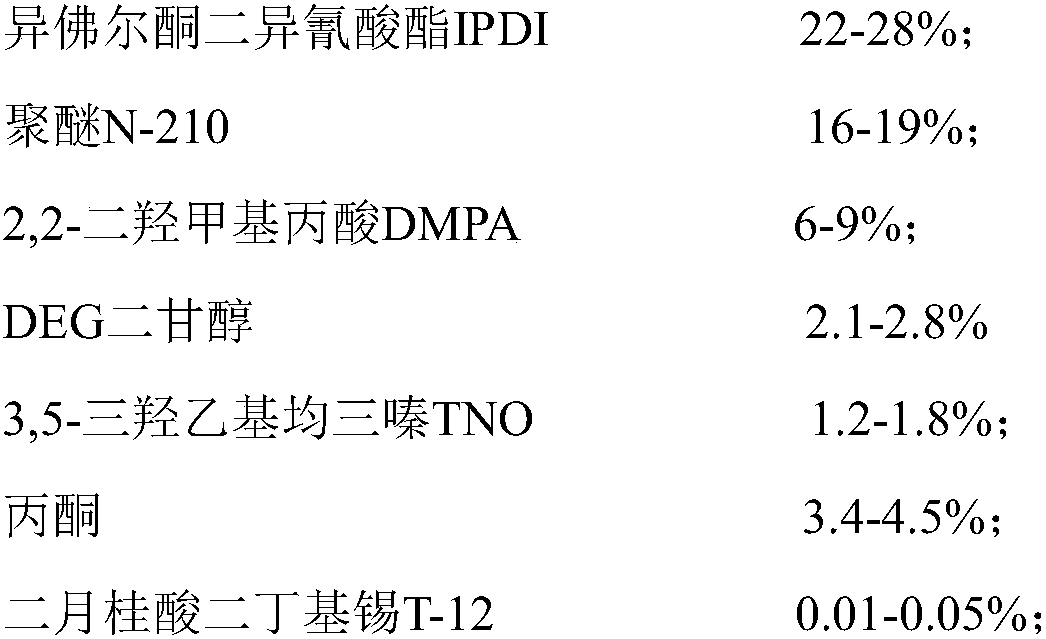

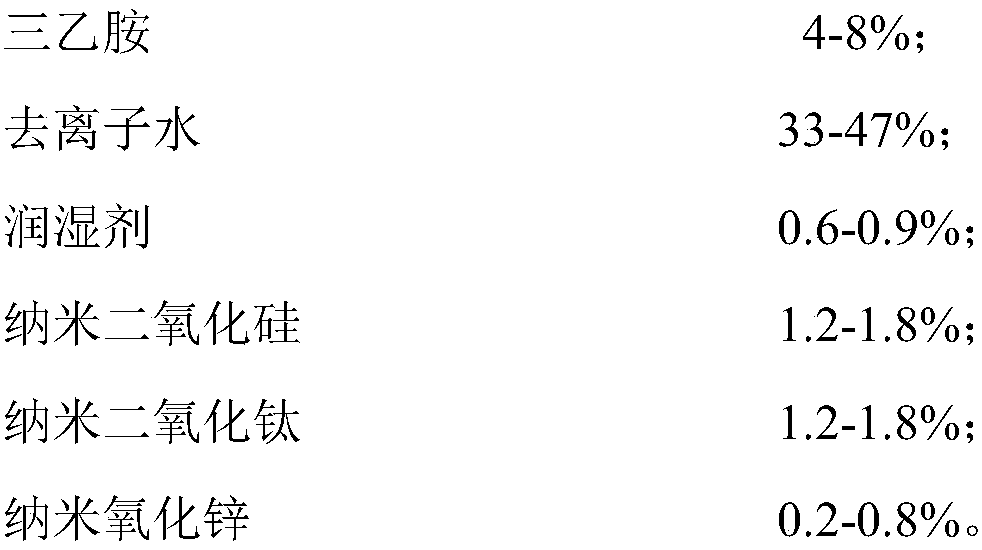

[0035] 1. Prepare nano-polyurethane emulsion.

[0036] Refer to the following table 1 material ratio.

[0037] Table 1 The material ratio of Examples 1-4 and Comparative Example 1

[0038] Component

Example 1

Example 2

Example 3

Example 4

Comparative example 1

A

IPDI

20

30

25

23

21.5

N-210

18

15

20

16

18

B

DMPA

8

5

5

10

8

C

DEG

2.5

2

3

2

2.5

TNO

1.5

2

1

1

0

4

3

5

3

4

T-12

0.05

0.01

0.03

0.04

0.05

D

8

5

3

10

8

E

Deionized water

33.35

33.99

32.47

31.96

33.35

0.8

1

1

0.5

0.8

Nano silica

1.5

1

2

1

1.5

Nano Titanium Dioxide

1.5

1

1.5

1

1.5

0.8

1

1

0.5

0.8

[0039] The preparation steps are:

[0040] 1. Blow nitrogen, add material A into the reactor, stir evenly, and raise the temperature to 90°C for 2 hours;

[0041] 2. Put in material B and keep it warm for 1 hour;

[0042] 3. Cool down and put in C material, react at 60℃ for 6 hours;

[0043] 4. Cool down to 30℃ and put it into high-speed dispersing kettle, add D material to neutralize;

[0044] 5. The water added to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com