Building corrosion-resistant epoxy resin paint

An epoxy resin coating and epoxy resin technology, applied in the coating field, can solve the problems of difficulty in adapting to heavy anti-corrosion requirements in the construction field, poor heat and humidity resistance, and poor weather resistance, and achieve the problems of easy cracking, improved anti-corrosion performance, and increased flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of corrosion-resistant epoxy resin coating for building, the weight percent of each raw material is: 45% of corrosion-resistant epoxy resin, 12% of titanium dioxide, 15% of composite ultraviolet shielding agent, 5% of curing agent, 0.5% of leveling agent , defoamer 0.3%, cyclohexanone 22.2%;

[0048] The preparation method of described corrosion-resistant epoxy resin specifically comprises the following steps:

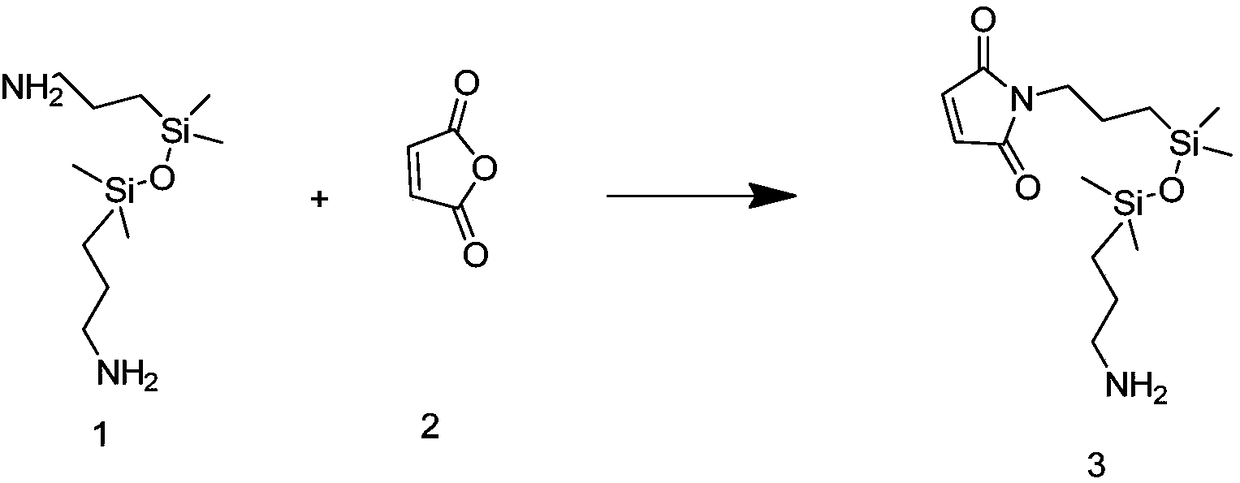

[0049] S1. Synthesis of modified silicone resin

[0050] Add 100 mol of amino silicone resin 1, 95 mol of modifier maleic anhydride 2 and 1.5 L of solvent N,N-dimethylformamide into the reaction flask, and heat it to 95°C for 40 min in a nitrogen atmosphere. Next, 2 mol of acid catalyst sulfamic acid was added, the temperature was raised to 135° C., and the ring closure and dehydration reaction was carried out for 3 hours to obtain the modified silicone resin 3;

[0051] The reaction formula is as follows:

[0052]

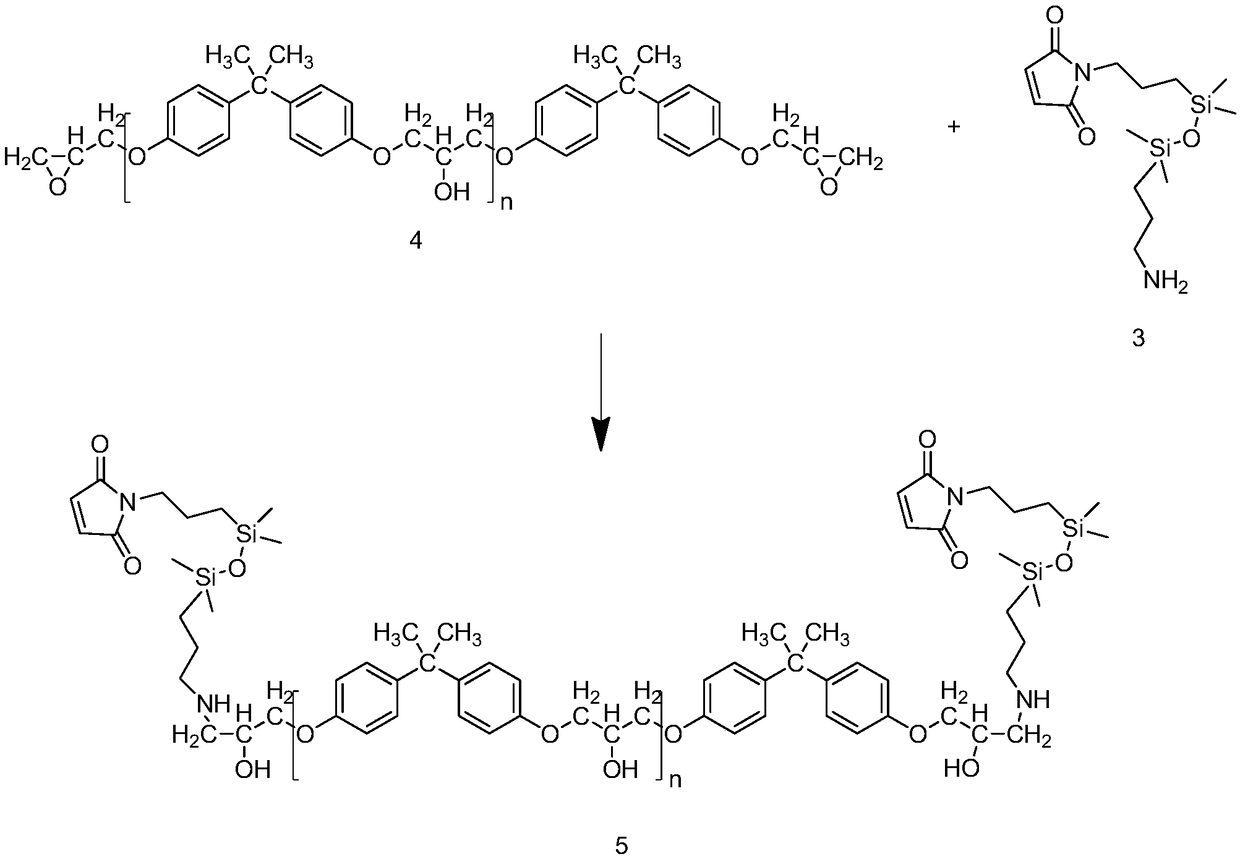

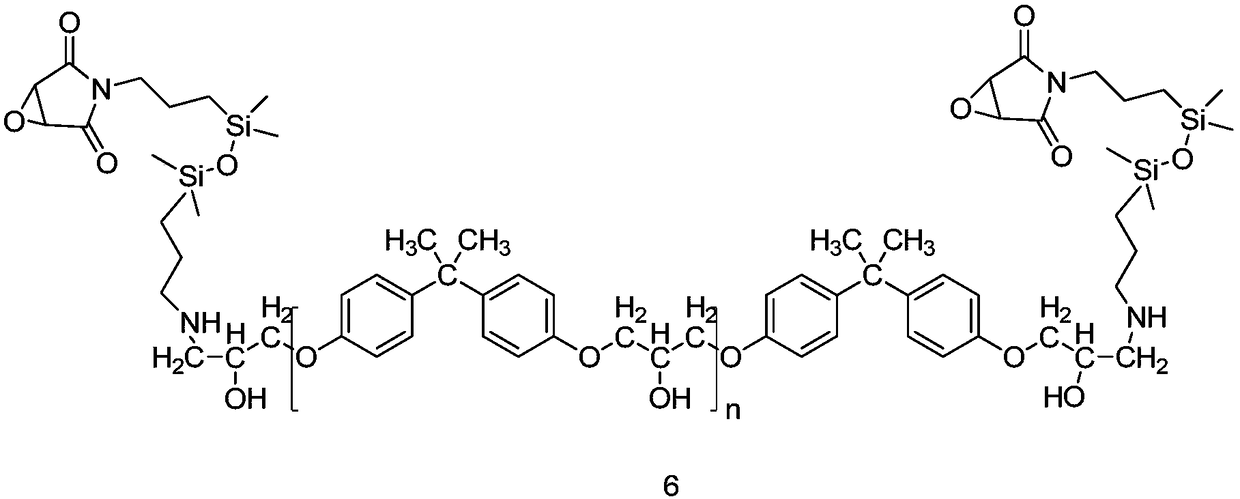

[0053] S2. Compounding of modifi...

Embodiment 2

[0066] A kind of corrosion-resistant epoxy resin coating for building, the weight percent of each raw material is: 60% of corrosion-resistant epoxy resin, 10% of titanium dioxide, 10% of composite ultraviolet shielding agent, 3% of curing agent, 1.2% of leveling agent , defoamer 0.8%, cyclohexanone 15%;

[0067] The preparation method of described corrosion-resistant epoxy resin is with embodiment 1;

[0068] The preparation method of described composite ultraviolet shielding agent is the same as embodiment 1.

Embodiment 3

[0070] A kind of corrosion-resistant epoxy resin coating for building, the weight percentage of each raw material is: 55% of corrosion-resistant epoxy resin, 14% of titanium dioxide, 13% of composite ultraviolet shielding agent, 6.5% of curing agent, 1% of leveling agent , defoamer 0.5%, cyclohexanone 10%;

[0071] The preparation method of described corrosion-resistant epoxy resin is with embodiment 1;

[0072] The preparation method of described composite ultraviolet shielding agent is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com