Sand blasting device for processing automobile accessories and parts and sand blasting method thereof

A technology for sandblasting devices and auto parts, which is applied to used abrasive treatment devices, metal processing equipment, manufacturing tools, etc. Strong sustainable operation ability, improved production efficiency and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

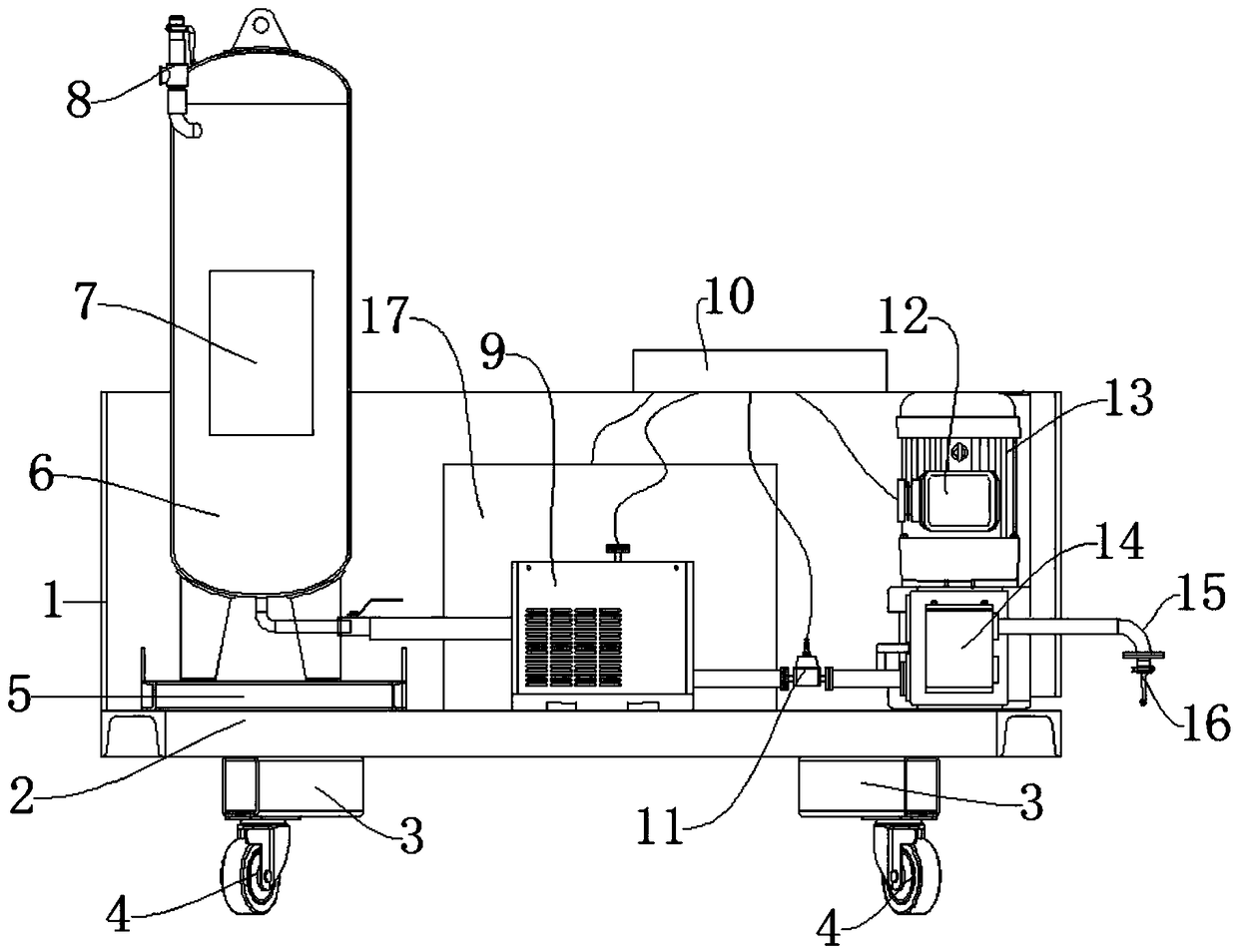

[0024] Such as Figure 1-Figure 4 As shown, a sandblasting device for processing auto parts, including a closed box 1 and a vibrator 9, the bottom of the closed box 1 is provided with a chassis 2, and the bottom of the chassis 2 is connected by a detachable connection module 3 Connected with the walking wheels 4, the top of the chassis 2 is connected with the spray tank 6 through the buffer base 5, the side wall of the spray tank 6 is provided with an observation window 7, and the top of the spray tank 6 is set There is a material injection valve 8, the spray tank 6 is connected to the vibrator 9, a flow meter 11 is arranged between the vibrator 9 and the high-pressure host 14, and the other end of the high-pressure host 14 is passed through a guide The flow tube 15 is connected to the sandblasting nozzle 16, the side of the vibrator 9 is provided with a battery box 17, the high-voltage host 14 is connected to a pressurizing motor 13, and the pressurizing motor 13 is electrica...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is:

[0027] In this embodiment, the spray tank 6 communicates with the vibrator 9 through a soft rubber pipe, the vibrator 9 contains a vibrating motor, and the vibrator 9 is connected to the flow meter 11 Connected through hard pipes.

[0028] Specifically, such setting is convenient for the vibrator 9 to vibrate the sand material and the spray liquid through the soft rubber pipe to avoid its precipitation, and the flow meter 11 can be used to count the amount of materials in real time, which is convenient for the staff Check.

[0029] The present invention also provides a method for using a sandblasting device for processing auto parts, which is applied to the above-mentioned sandblasting device. Stored in the spray tank 6 for use, the staff can pull out the fast charging plug 18, find the charging line board, charge the battery box 17, and then drive it manually or by external mechanical power The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com