Tank reactor for producing surfactants, and application method thereof

A kettle-type reactor and surfactant technology, applied in the field of kettle-type gas-phase sulfonation reaction equipment, can solve problems such as reducing the viscosity of raw materials, difficulty in tail gas treatment, and loss of raw materials, so as to improve selectivity and avoid over-sulfonation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

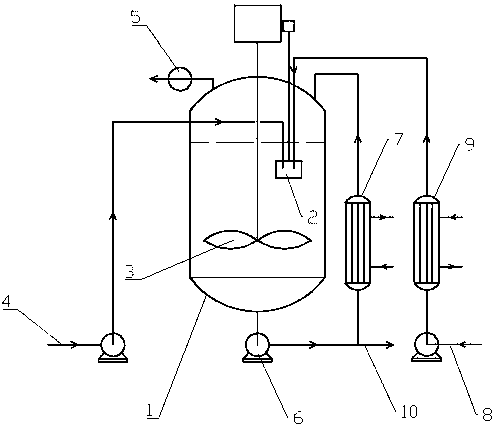

[0030] Embodiment 1 A kind of tank reactor for producing surfactant

[0031] Such as figure 1 In the shown embodiment, a kind of tank reactor that is used to produce surfactant comprises buffer tank 1, the gas-liquid mixer 2 that is arranged in buffer tank 1, the agitator 3 that is arranged in buffer tank 1, and The diluted raw oil inlet 4 connected to the gas-liquid mixer 2 in the buffer tank 1, the vacuum pump 5 connected to the buffer tank 1, the circulation discharge system arranged outside the buffer tank 1 and the diluted sulfur trioxide arranged outside the buffer tank 1 Feeding system; the circulating discharge system includes a circulating discharge pump 6 and a heat exchanger 7, one end of the circulating discharging pump 6 communicates with the bottom of the buffer tank 1, and the other end of the circulating discharging pump 6 communicates with one end of the heat exchanger 7 , the other end of the heat exchanger 7 communicates with the buffer tank 1 top; the circ...

Embodiment 2

[0034] Embodiment 2 A kind of use method for the tank reactor of producing surfactant

[0035] The using method of the present embodiment is based on a kind of tank reactor for producing surfactant in embodiment 1, specifically comprises the steps:

[0036] (1) Separately dilute the raw material oil and sulfur trioxide: subtract the fourth-line raw material oil, the boiling range is 450-500°C, dilute according to the weight ratio of raw material oil: dichloromethane = 1:1.5, SO 3 Dilute with dichloromethane at a weight ratio of 1:2;

[0037] (2) Add 1000Kg of diluted raw oil into the buffer tank 1;

[0038] (3) Turn on the agitator 3, turn on the cold water jacket of the buffer tank 1, wait until the temperature in the buffer tank 1 drops to 10°C, turn on the vacuum pump 5 to evacuate, and maintain the negative pressure in the buffer tank 1 at 2mmHg;

[0039] (4) Start the gas-liquid mixer 2 in the buffer tank 1;

[0040] (5) The temperature of the evaporator 9 is 30°C, sta...

Embodiment 3

[0043] Embodiment 3 A kind of use method for the tank reactor of producing surfactant

[0044] The using method of the present embodiment is based on a kind of tank reactor for producing surfactant in embodiment 1, specifically comprises the steps:

[0045](1) Separately dilute raw oil and sulfur trioxide: mix vacuum residue, diesel oil, and dichloromethane at a weight ratio of 1:0.5:3 to prepare diluted oil, and sulfur trioxide and dichloromethane at a ratio of 1:2 The weight ratio is diluted;

[0046] (2) Add 1000Kg of diluted raw material oil into the buffer tank 1;

[0047] (3) Turn on the agitator 3, turn on the cold water jacket of the buffer tank 1, wait until the temperature in the buffer tank 1 drops to 10°C, turn on the vacuum pump 5 to evacuate, and maintain the negative pressure in the buffer tank 1 at 2mmHg;

[0048] (4) Start the gas-liquid mixer 2 in the buffer tank 1;

[0049] (5) The temperature of the evaporator 9 is 30°C, start to pump diluted SO into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com