Multi-axis motion control automatic coil winding machine

An automatic winding machine and multi-axis motion technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problem that the output of stator coils cannot meet market demand, the quality of winding cannot reach high-performance motors, and the processing efficiency is low And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

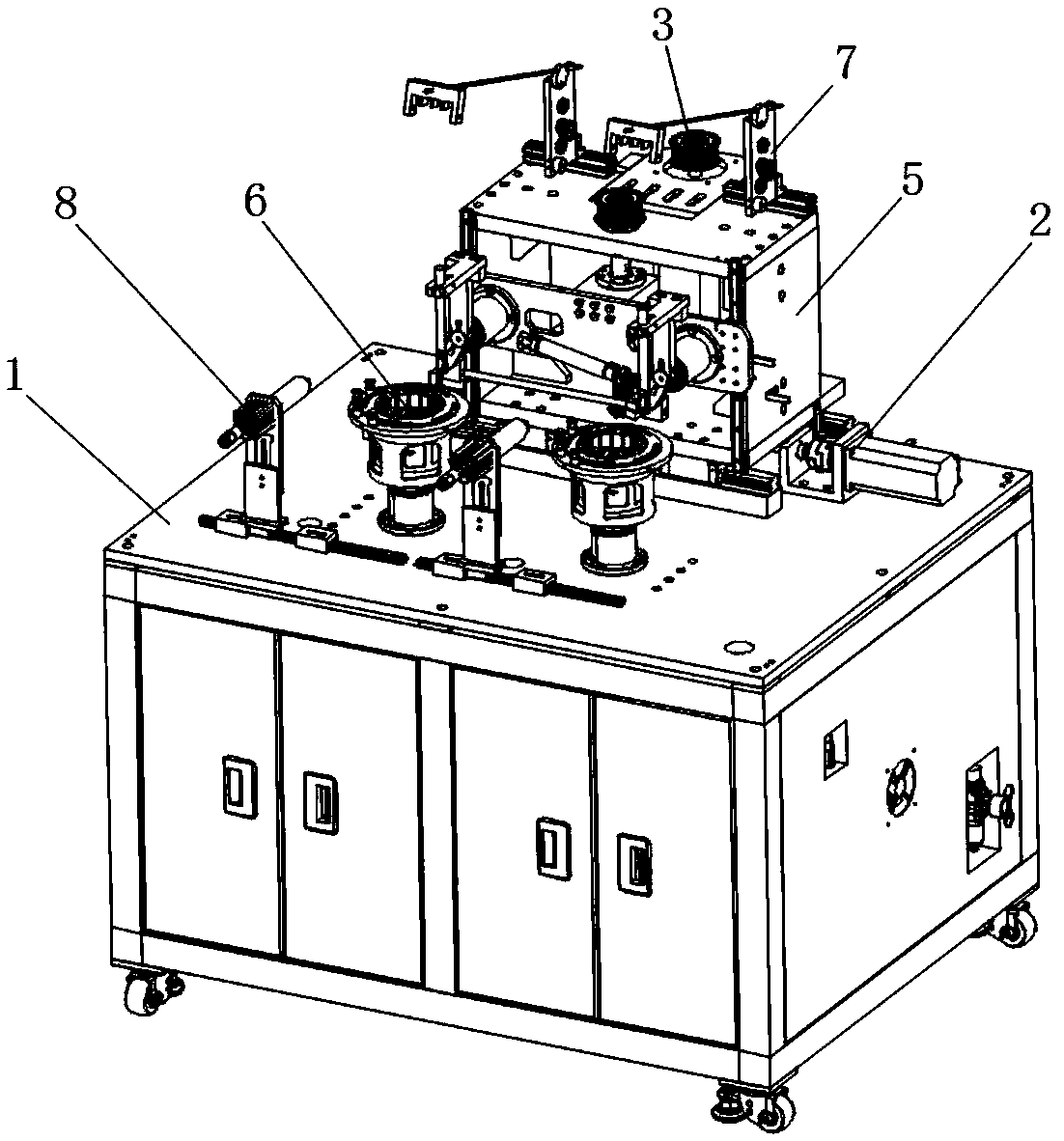

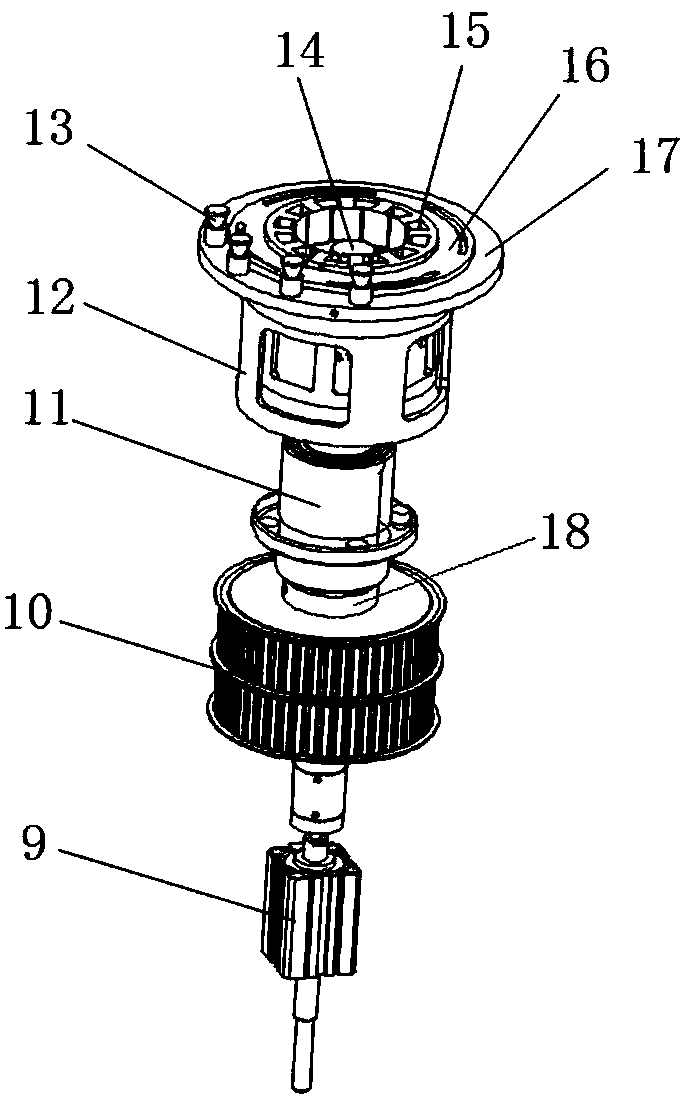

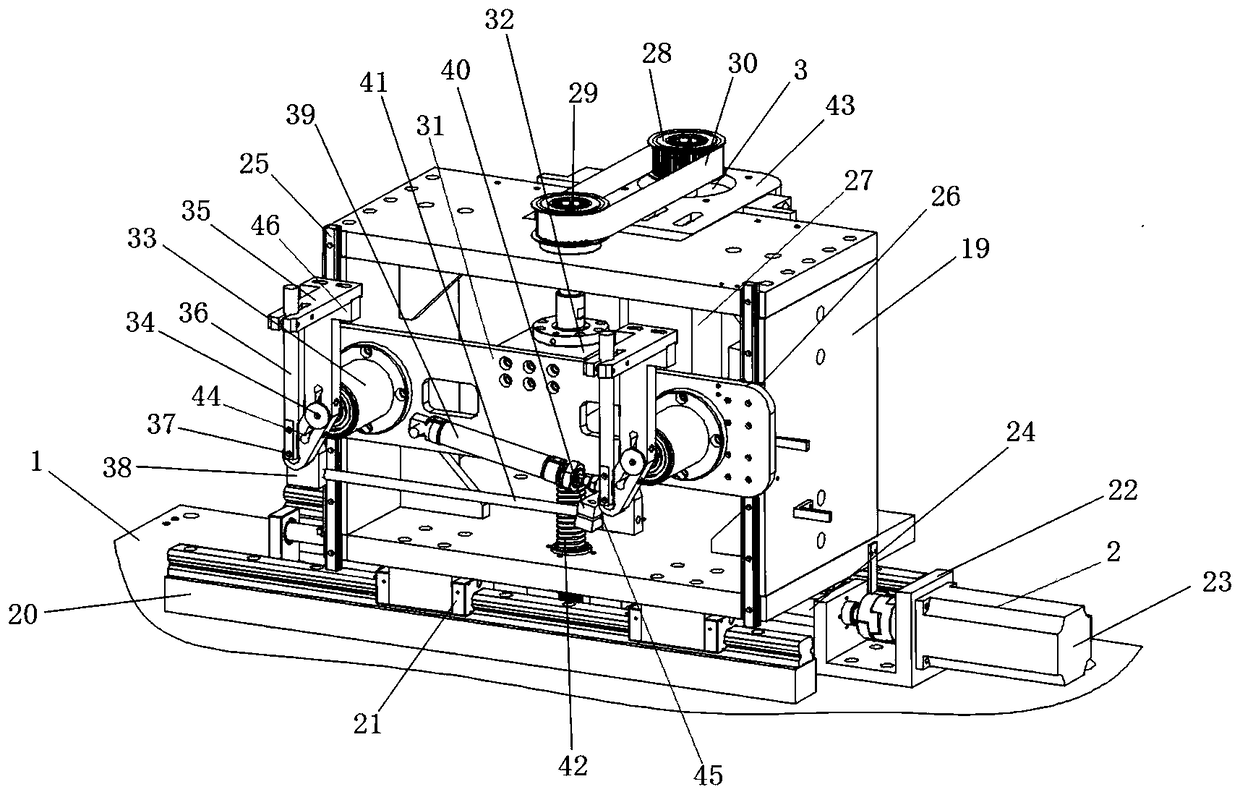

[0031] Embodiment: a kind of automatic winding machine of multi-axis motion control, constitutes as attached Figure 1-7 As shown, it includes a frame 1, the frame 1 is provided with a first transmission mechanism 2, and the first transmission mechanism 2 is provided with a winding mechanism 5, and the winding mechanism 5 includes a Sliding table 19, the top of sliding table 19 is provided with second transmission mechanism 3; The front portion of described sliding table 19 is provided with the horizontal plate 31 that connects second transmission mechanism 3, and the front portion of horizontal plate 31 is provided with two rotating shafts 33 , the front parts of the two rotating shafts 33 are respectively provided with a wire rod 34, and the two wire rods 34 are respectively provided with a rotating arm 46, and the first sliding hole matched with the wire rod 34 is provided on the described rotating arm 46 44, the tops of the two rotating arms 46 are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com